|

man im starting to get pissed. its been a week and they are blowing off my parts (all they have done is one set of corners and 3 fan shrouds).. So they go NOTHING done on them this week.. FUCK!

Really thinking of saying F-it and order this.. http://www.ultibots.com/mendelmax-1-5-printed-parts/ So sorry !andy2. im still waiting.. |

|

|

|

Quoted: Got my hardware that I ordered today.man im starting to get pissed. its been a week and they are blowing off my parts (all they have done is one set of corners and 3 fan shrouds).. So they go NOTHING done on them this week.. FUCK! Really thinking of saying F-it and order this.. http://www.ultibots.com/mendelmax-1-5-printed-parts/ So sorry !andy2. im still waiting.. Hope to really get going on it this weekend. |

|

|

|

Quoted: I have built a reprap recently. I have decided to get it working and calibrated with PLA first before I move on to ABS. I am having trouble with my X axis and backlash. I have a new T2.5 belt and pulleys coming. My question is how do you print some of the items off defcad? I am using repiter and when I load the item I can see it but I have to scale the item because it starts out super small. Whats the deal? Sign it a DEFCAD. They will help you with the problem. I havent got that far yet.  |

|

|

|

So it appears a sub $1k delta format printer is likely in my future. A hackerspace here in Seattle is connected to the guy who developed the original Rostock printer, and he is working on an update that uses lasercut parts and aluminum extrusions to create a pretty badass printer for way less than some of the Mendelmax kits. And it looks sexseh.

|

|

|

|

Quoted: Ok. So... bottom line: can I get set up with one of these things with a decent sized print envelope for less than $1k? And if so, where do I order it? I really, REALLY want one and I've got some extra cash right now, but the Mendelmax 2 full kit I've been looking at is $1.5k and I can't even find a price for the Deltamaker I was eyeballing. Update for you. $699 http://www.ebay.com/itm/RepRap-Prusa-i3-Mini-3D-Printer-/290909370896?pt=LH_DefaultDomain_0&hash=item43bb8cba10 |

|

|

|

Can you print a lower with this??

Quoted:

Quoted:

Ok. So... bottom line: can I get set up with one of these things with a decent sized print envelope for less than $1k? And if so, where do I order it? I really, REALLY want one and I've got some extra cash right now, but the Mendelmax 2 full kit I've been looking at is $1.5k and I can't even find a price for the Deltamaker I was eyeballing. Update for you. $699 http://www.ebay.com/itm/RepRap-Prusa-i3-Mini-3D-Printer-/290909370896?pt=LH_DefaultDomain_0&hash=item43bb8cba10 |

|

|

|

Quoted: Can you print a lower with this?? Quoted: Quoted: Ok. So... bottom line: can I get set up with one of these things with a decent sized print envelope for less than $1k? And if so, where do I order it? I really, REALLY want one and I've got some extra cash right now, but the Mendelmax 2 full kit I've been looking at is $1.5k and I can't even find a price for the Deltamaker I was eyeballing. Update for you. $699 http://www.ebay.com/itm/RepRap-Prusa-i3-Mini-3D-Printer-/290909370896?pt=LH_DefaultDomain_0&hash=item43bb8cba10 Lets see. Max object dimension. 4x4x4 1/2 scale maybe.  |

|

|

|

|

|

Staples started selling the Cube 3D Printer from 3D System on Friday May 3, 2013.

Price $1300 http://www.pcmag.com/article2/0,2817,2418523,00.asp |

|

|

|

US company makes gun created entirely from 3D printer Published: May 4, 2013  http://www.mb.com.ph/article.php?aid=10485&sid=1&subid=6#.UYSeVMrXqRM The Liberator is made out of 16 plastic components, with a nail that serves as a firing pin. To comply with the US Undetectable Firearms Law, Defense Distributed is inserting a six ounce chunk of steel in the gun to make it detectable to metal detectors. But once the company uploads the plans for the gun onto the internet, budding amateur 3D printer enthusiasts can print their own version of the Liberator without the required part. |

|

|

|

Oh well

Quoted:

Quoted:

Can you print a lower with this?? Quoted:

Quoted:

Ok. So... bottom line: can I get set up with one of these things with a decent sized print envelope for less than $1k? And if so, where do I order it? I really, REALLY want one and I've got some extra cash right now, but the Mendelmax 2 full kit I've been looking at is $1.5k and I can't even find a price for the Deltamaker I was eyeballing. Update for you. $699 http://www.ebay.com/itm/RepRap-Prusa-i3-Mini-3D-Printer-/290909370896?pt=LH_DefaultDomain_0&hash=item43bb8cba10 Lets see. Max object dimension. 4x4x4 1/2 scale maybe.

|

|

|

|

Quoted: With a little imagination and engineering. You could make a .22 or short or .25 caliber variants.Oh well Quoted: Quoted: Can you print a lower with this?? Quoted: Quoted: Ok. So... bottom line: can I get set up with one of these things with a decent sized print envelope for less than $1k? And if so, where do I order it? I really, REALLY want one and I've got some extra cash right now, but the Mendelmax 2 full kit I've been looking at is $1.5k and I can't even find a price for the Deltamaker I was eyeballing. Update for you. $699 http://www.ebay.com/itm/RepRap-Prusa-i3-Mini-3D-Printer-/290909370896?pt=LH_DefaultDomain_0&hash=item43bb8cba10 Lets see. Max object dimension. 4x4x4 1/2 scale maybe.  |

|

|

|

OK looks like the school was a blow out.. they are dicking me around,oh ya oh ya were right on it.. next day nothing.. Screw it ordered 2 sets of plastic from ebay.. Should have it next week..

|

|

|

|

Tag.

I've got a Raspberry Pi and was thinking about making a small CNC mill for plastics and perhaps wood. I was looking at a Shapeoko, but this stuff it VERY interesting. |

|

|

|

Quoted: Tag. I've got a Raspberry Pi and was thinking about making a small CNC mill for plastics and perhaps wood. I was looking at a Shapeoko, but this stuff it VERY interesting. Watching videos of the Shapeoko. Nice toy. But the dremels are freaking loud.  |

|

|

|

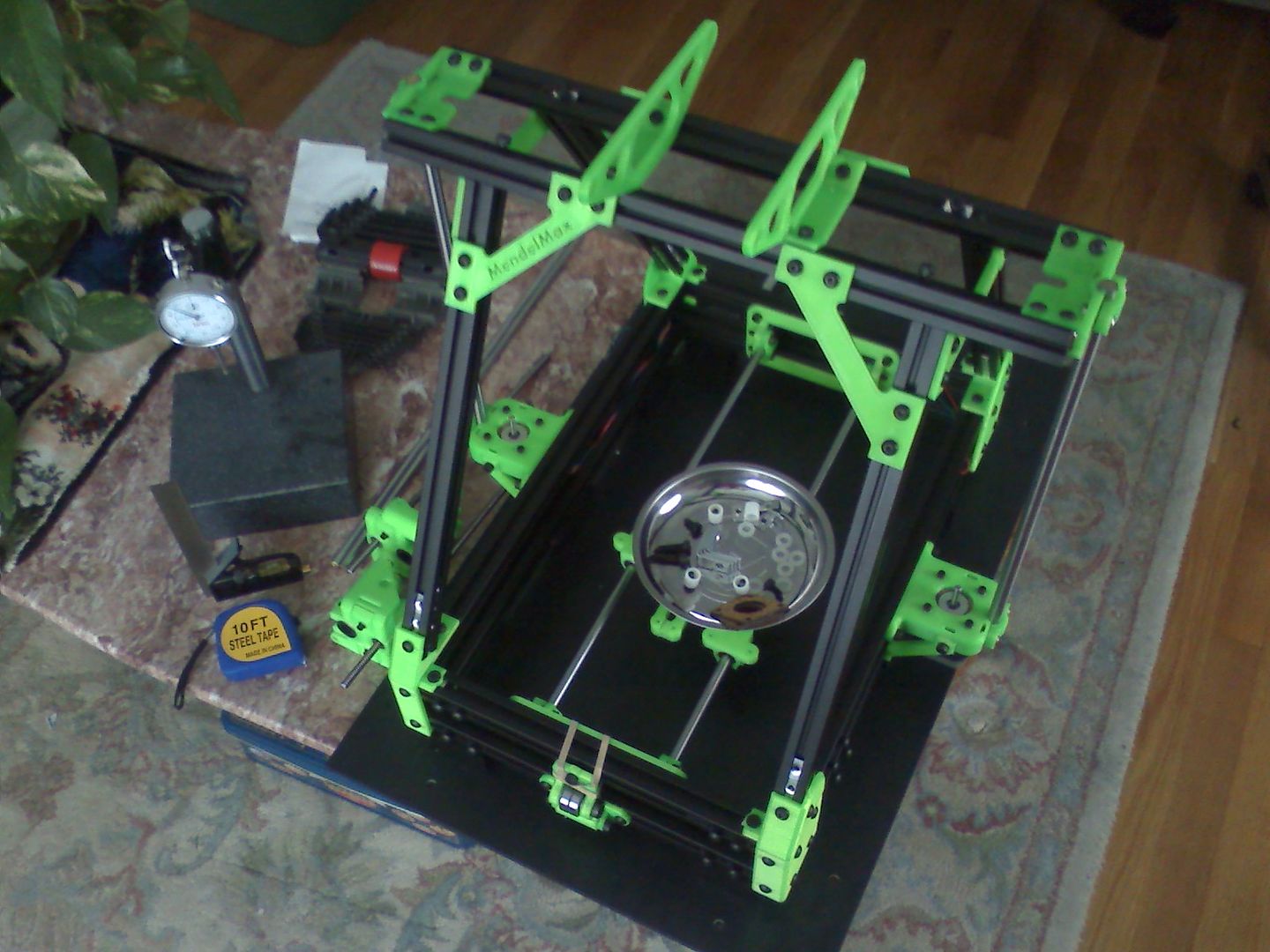

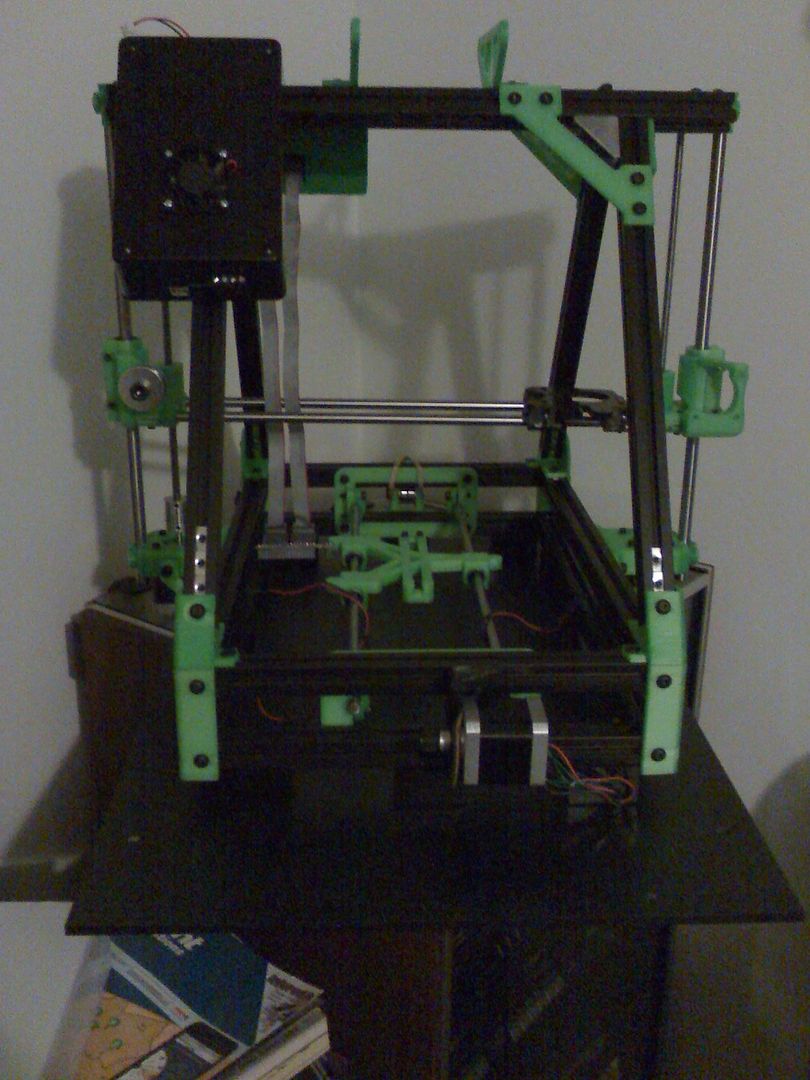

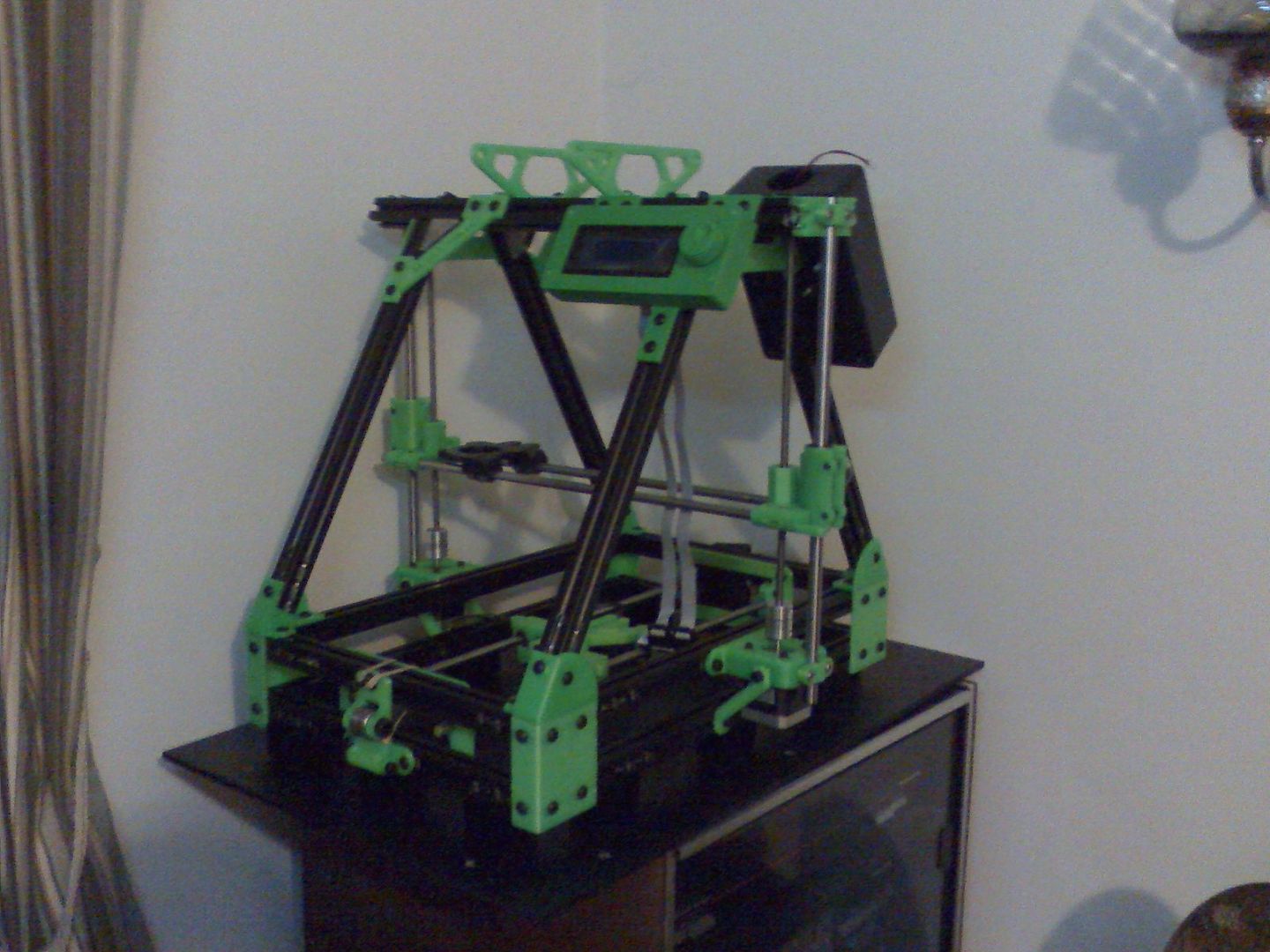

Quoted: OK looks like the school was a blow out.. they are dicking me around,oh ya oh ya were right on it.. next day nothing.. Screw it ordered 2 sets of plastic from ebay.. Should have it next week.. Finally got the base assembled and aligned less motor an belt. Lots of flashing and nut seating problem. Used one of the extrusions and placed it across the top of the base and checked the rods to see how far off the were. I started at .030 for a high and .004 for a low. It took a while but I got them at +/_ .003. The only way to get it better I would need to make a front and rear adjustable jig to hold the plastic from moving when tightening the screws. I just finished assembling the upper frame. Had to replace a torxs screw on one leg. The head stripped and I could not tighten it up. I replaced it with a M5x1- BHCS. Could have used an extra pair of hands to set the clamps to hold the legs in position. Twisting problems. Both upper Z vertex had to be trimmed with an Xacto to fit over the extrusion. Also I have two holes on both of them filled with plastic. I don't know if these parts are made with ABS or PLA. A bunch of kits on Ebay are PLA which would be bad for parts near the heating pad or extruder. One guy is selling emergency parts that may let go because of heat issues on first prints. |

|

|

|

What a Sunday.

I fell asleep on the couch. Got calls from telemarketers. Got call from my little sister who's dishwasher backed up into the house. The waste hose got really plugged' Just got home. Having a tough time slotting out the holes for the 5mm nuts. the deeper the slot the harder it is to slice open with the Xacto knife. There has to be something better out there to clean this slots out. Broke a blade tip in the process. Once they are open enough I can press them in. Dropped one of the nuts. It kicked away when I got up. It took me about 25 minutes to find it. I swept around until I heard it slide on the floor. I will order some extras from MSC Item #60329810. These are special thin M5 nuts. The are 2.7mm thick and not the usual 4mm thick. Also they are a jam nut. Had to take the Top Vertex apart to add more t-nuts. At 16 per legs and an additional 12 per cross member. Good thing I have an extra 200 pieces left over after adding the extra t-nuts.. Assembling the X-axis to complete the Z-Axis. Should be adding the wires by Tuesday. Also. I had to polish the shafts with scotch brite thanks to the gritty feeling along the shafts. Corrosion. Low grade stainless. Magnets stick to it. Also I think they are soft and not harden. I'll get a hardness test done on one tomorrow. That will ID the type of shaft. It may just be rod material. I'll call around this week during the day to the local glass shops for the Borosilicate Glass. I'll leave the top sheet metal plate as a sample. Ill order a spare at the same time. |

|

|

|

Quoted: Got marlin installed. Not much else I can do right now.  I know the feeling. The waiting sucks. Just finished the order for nuts and hand drill from MSC and Pro Flowers for Friday delivery for Mom. Too tired right now to do any work on the Mendelmax. Thirsty as hell right now. Burning sinus and sore throat. Thinking of making some acrylic panels like the Vision ones on page 8. But mine will either fold down on a hinge or slide out. It will shield the parts from cool air and keep prying fingers out. Already had people playing with the parts on the Mendy. Hate to see what will happen when it is running. Wait. I do want to see their face when a finger is pinched or burnt. |

|

|

|

|

|

|

|

|

|

WOW! Just checked it out. That is one great deal. As a kit. I cant touch it by buying individual items. If I were building another Mendy, it would be the best deal. The corners(4 for $5.95) and power jacks($2) are a really good deal. Too much invested in this one. I'll have to use it the way it is for now. But for using the rails system on the CNC,well that is a different story. The Igus rail is $53 dollars for a 4000mm long x 80mm wide. Pro-rated price for less than 4000. A 120mm wide is I think $68. I think the are using a 40mm. Cheaper to buy the longer rail and split the difference between two machines and salvage the parts from the old Z-axis parts on the Mendy therefore saving money. |

|

|

|

|

|

Ordered the corner brackets(2-set of 4), M5 trim caps(2-packs of 4), 2.1 phone power jack (4), and a printed LCD display box(green). Dont want to damage the display board by hanging it in a stupid way. Its well worth the $12. |

|

|

|

Got the spare M5 thin nuts coming in today.

Also two pin vises. The pin vise will be useful in opening up holes in the plastic parts. This one will take up to .250 inch.  You can use a drill or reamer. The latter being the most expense of the two. The larger pin vise would be the Vargus brand Vargus Pin Vises | Type: Handy Chuck Pin Vise | Capacity Range: 0.010 - 0.312 $31.08 ea. Funny how the price kind of matches the maximum size on this one. |

|

|

|

Well. The only thing that has gone right today is that my MSC parts and tools came in today.

On the other hand the motor won't install because the M3x10 SHCS (18 pcs)are too short. I really need M3x12mm but I only have 3 in the kit. The rod clamps on the X-axis need a min of M3x16 to work. The local hardware store doesn't carry squat. Called the local KL Jack for the hardware and they would have to order the screws. The dimensions of these part are thicker than the hardware that is called out. With all the replacement wrong and missing hardware. The missing mounting holes. No manual for the kit. Paying and waiting for the hardware to arrive. This kit is a huge disappointment. |

|

|

|

Not to sound like an ass, but why do they need to be metric? Drill the holes out to the next size up...SAE... and get them at the local hardware store. Buy longer ones than you need, and trim to length if you need to do so.

|

|

|

|

|

|

Quoted: Not to sound like an ass, but why do they need to be metric? Drill the holes out to the next size up...SAE... and get them at the local hardware store. Buy longer ones than you need, and trim to length if you need to do so. All the Misumi products are in metric. Only the 10 Series and up can use the fractional T-nuts. Also most of these units are designed in Europe so the dimension of the models/parts are also metric. Only models/parts designed in fractional/decimal measurements. |

|

|

|

Quoted:

Decided to play with this kit some more. Maybe I should not have. Bottom of Y-axis plates. Note how far off the holes are to the others. http://i2.photobucket.com/albums/y22/TractorDre/AR15/Mrndelmax%201%205/Yaxisholes1_zps0f9b42ce.png Top view of the plates. http://i2.photobucket.com/albums/y22/TractorDre/AR15/Mrndelmax%201%205/Yaxis2_zpsf35c72ea.png It is what happens when you are in a hurry. This kit is turning into a disaster. Nice kit Mikey holy shit snacks! |

|

|

|

Just got an email from the seller.

Told me that I was the worst customer he ever had. Yada,Yada Yada. It was his first time getting a negative review. I hurt little Bobbies whittle feelings  Well I answered him back with the above picture indicating what I was going through.Also included his shipping games, lack of manuals and other poor business practices. My fault. I should have paid more and ordered from more reliable source. Like they say. You get what you paid for. I wasted $550 on a kit that has to be restored. Yes restored to be called a Mendelmax. |

|

|

|

Just got this for an answer

Try flipping the lower plate around. You'll see it matches up. The plates are drilled through each other to guarantee that they match up. Another example of you not being up to task. Thank you for proving my point that you really don't know what your talking about. Really? Sent him this. Look who's talking. Turned it around for you. Now the sides don't line up and the panel is twisted. Running it this way the table would be of a bit. BTW. I have over 20 years of building multi axis system, pick and place systems, CNC(Sand blaster curtains, laser CNC) and the M60A3 Optical laser range finder for 5 of those years. Andre  |

|

|

|

looks fine, just auger out the holes a bit..

and the LRF for the M60A3 was a heavy bitch. |

|

|

|

Quoted: I'll clamp it down on the good side and drill press the two bad holes. I'll replace the metric screws with fractional and use either star washers or lock nuts so it doesn't slide apart.looks fine, just auger out the holes a bit..  and the LRF for the M60A3 was a heavy bitch. It is amazing what kind of sellers are out there. This was my real bad one yet. The LRF was my main build at building 3 on Nashua. The optical bench was delicate in a way. Once installed wasn't bad to handle LRF until I mounted the mirror. Then things really got heavy.It became awkward to move. Back then I moved them by myself around the floor on the wooden fixtures. But in the alignment room I had to use the hoist because of the confined space of the alignment fixture. End of the month push really sucked when DCAS or inspection found dirt or lint inside of one. Then it had to remove the covers in the clean room, clean, production tested, leak test, quality test, vibration, back to quality test then final inspection. Then checked. If dirty then it was started all over again. Ever try to ID what surface that the dirt was on without opening it from some 20+ surfaces of glass? Some had folders that were two to three inches thick for one assembly. It felt heaver than the cant angle unit. Once I had burned out the eyes in ID Badge with the laser as part of a bet on my accuracy. Got a free lunch. Drove the guards crazy when they looked at my picture. I looked like someone from the village of the damned. I miss those day |

|

|

|

|

|

|

|

|

|

|

|

Quoted:

This might be nice as a gift. Its also on Thingiverse. http://www.thingiverse.com/thing:12472 Someone should rebuild Dave Gingery's lathe in CAD. |

|

|

|

MSC was fast.

Just got home and my hardware that I ordered yesterday was already here since 1PM. |

|

|

|

my update.. got my parts kit form China.. holy shit its rough. and I hope this is not the quality that the printers print at.

|

|

|

|

I'll bet they sacrifice alot of resolution/smoothness for speed.

|

|

|

|

Quoted:

I'll bet they sacrifice a lot of resolution/smoothness for speed. they did.. I grabbed one of the bags threw it in a box and it will be on its way tomorrow. Ill will end up reprinting a set as soon as I can get my system up and running. If I can get some good prints Ill throw a few sets up in the EE. For other members.. |

|

|

|

Quoted:

Got the spare M5 thin nuts coming in today. Also two pin vises. The pin vise will be useful in opening up holes in the plastic parts. This one will take up to .250 inch.

http://cdn.mscdirect.com/global/images/ProductImages/8649199-23.jpg You can use a drill or reamer. The latter being the most expense of the two. The larger pin vise would be the Vargus brand Vargus Pin Vises | Type: Handy Chuck Pin Vise | Capacity Range: 0.010 - 0.312 $31.08 ea. Funny how the price kind of matches the maximum size on this one. That looks like a useful tool. I'm always just using drill bits with my finger tips, or a portable drill to clean up holes which risks damaging the hole. That tool would give me enough force to do it by hand correctly. |

|||||||||||||

|

|

|

Quoted: Yes these are great to have around.Quoted: Got the spare M5 thin nuts coming in today. Also two pin vises. The pin vise will be useful in opening up holes in the plastic parts. This one will take up to .250 inch. <thead><th>Select </th> <th> Product Image </th> <th colspan="2"> PRODUCT DETAILS </th> <th> ADD ORDER </th> </thead>

http://cdn.mscdirect.com/global/images/ProductImages/8649199-23.jpg You can use a drill or reamer. The latter being the most expense of the two. The larger pin vise would be the Vargus brand Vargus Pin Vises | Type: Handy Chuck Pin Vise | Capacity Range: 0.010 - 0.312 $31.08 ea. Funny how the price kind of matches the maximum size on this one. That looks like a useful tool. I'm always just using drill bits with my finger tips, or a portable drill to clean up holes which risks damaging the hole. That tool would give me enough force to do it by hand correctly. These are some of the other tools that I been using on this project.  Note how I am using a countersink for a deburring tool. |

|||||||||||||

|

|

|

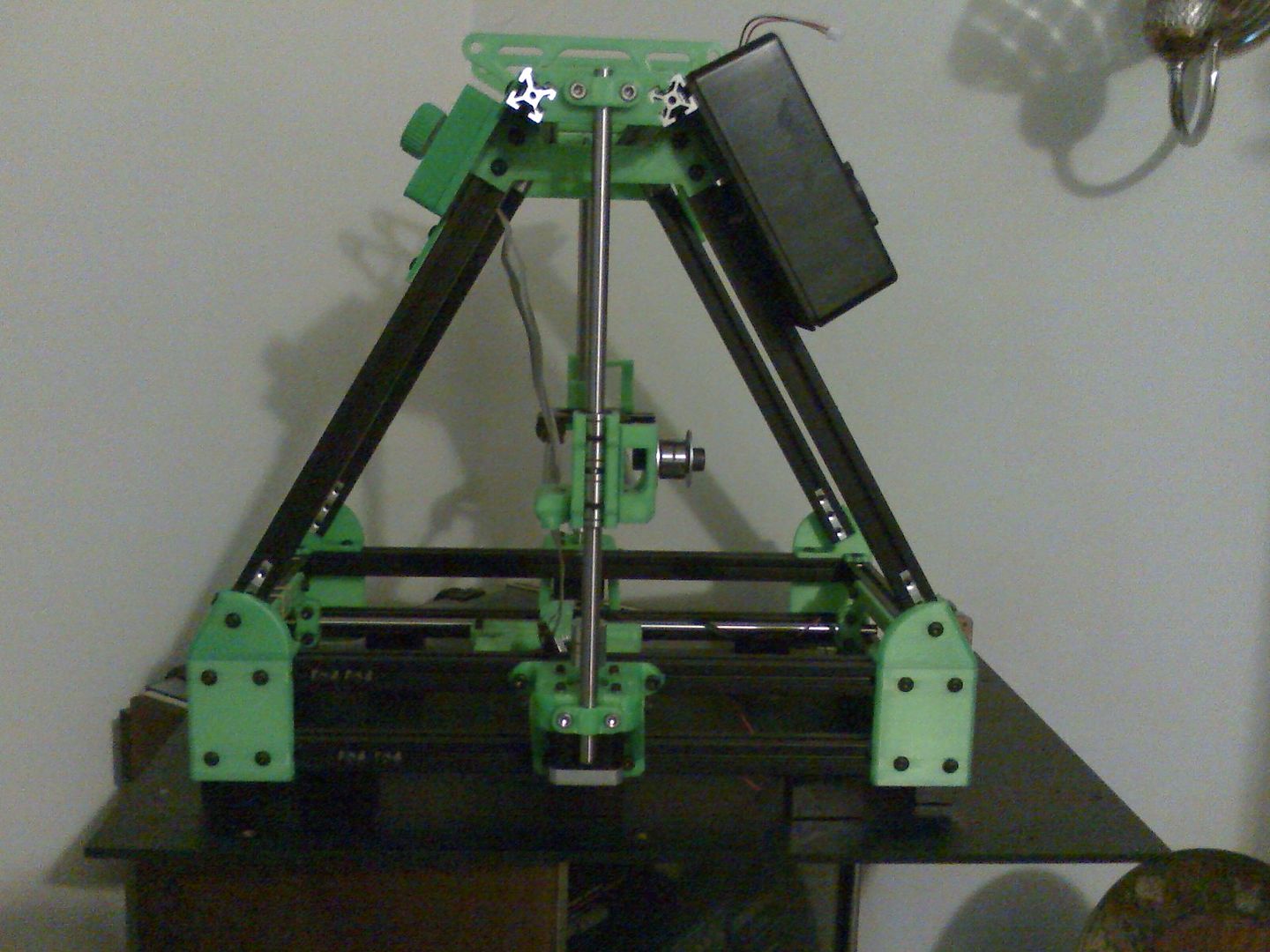

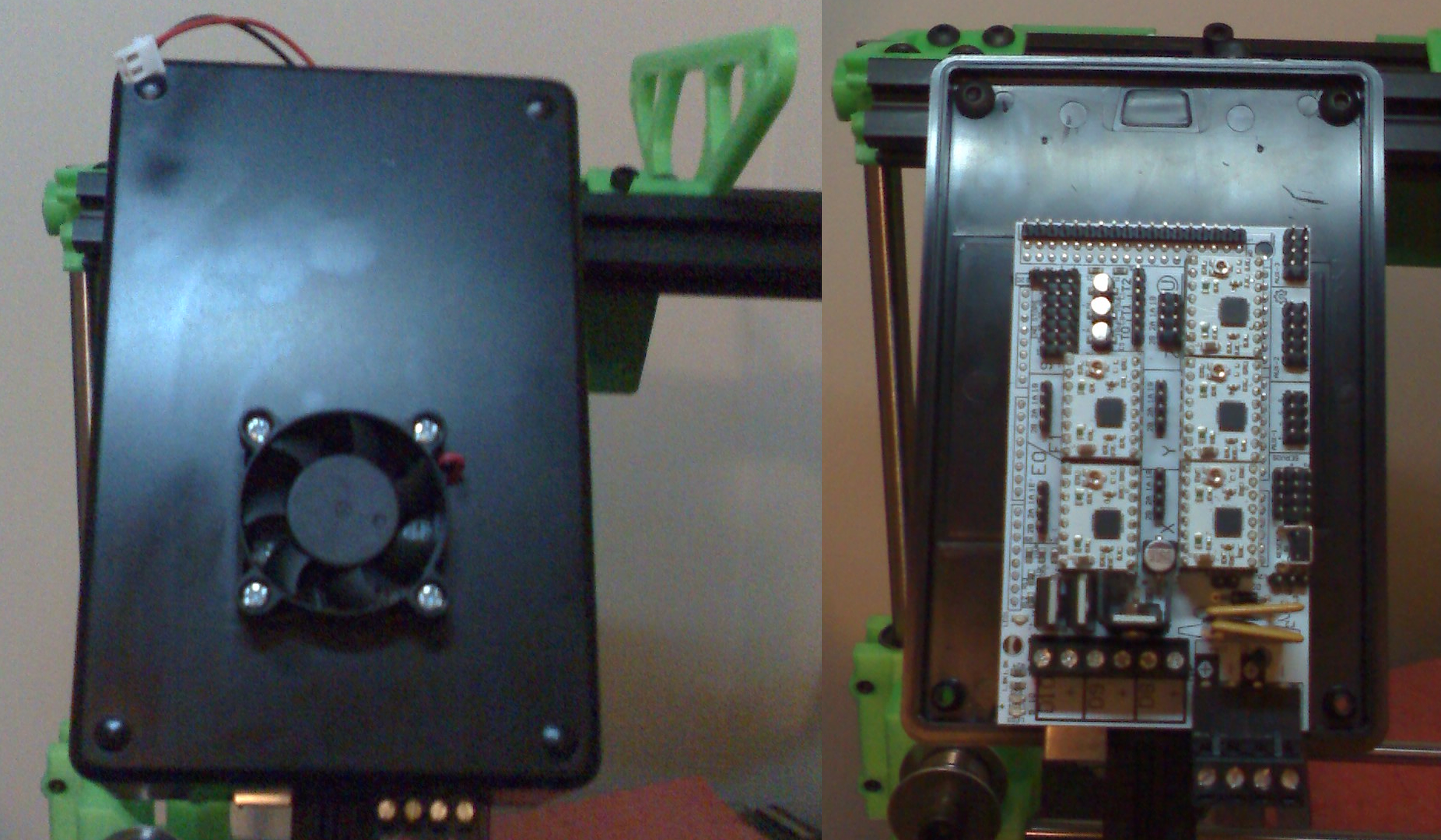

I used a nylon washer inside both Z axis carriers to prevent the spring from pushing through and getting stuck inside jamming the lead screw.  Saturdays assembly and stopped to take care of the spring problem.  Monday the Display box arrived with some other hardware from Utilsbot.com. Their plastic parts were of better quality than the Mech assy.OK. I didnt specify the type of green but the display board is safer inside of the box. Also note the new corner braces in the Upper Vertex Assy. Got them from Utilsbot.com  This a Radio Shack Project box being used for the Main board an driver assy. I have one fan mounted but not the top one.  I have not made the holes for the cables yet but a 12v terminal block will be going in above the board.    |

|

|

|

I have been following this thread since I find the concept of 3D printing interesting, but I am new to the whole thing and not up for rolling my own.

Given your experience with all of the components, could you take a look at this to see if it would work for me to get started? Or would it be a big letdown for $400? RigidBot 3D Kickstarter I would not be doing anything serious, just for personal geeking out. Thanks. ETA: Oops, found a thread on it when I set my search parameters right. I'll read that up....free bump anyways. |

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.