Same here. I'm trying real hard not to do it until the AR is built and I find out if I need them (I have mismatched upper and bbl). Wouldn't want to unnecessarily damage that fancy cmmg bbl. |

|

|

|

Wow, I know this is a little late. Danny, I didn't know that upper had M4 feed ramps, I want that upper back. Just joking. |

|

|

|

|

|

|

|

Thanks for you opinion Mongoo1 I will be contacting RRA for correction...Thankx |

||

|

|

Actually, no real problem exists right now, just a potential for a problem and that problem may only show itself in full auto operation with a mag that has a weak srping. If you don't have either of those, it would likely operate just fine as is. I would run it for awhile to see how it goes. You will likely never see a problem. |

|||

|

|

|

"The extended feed ramps were necessary to ensure that the thin-jacketed 77-grain Match King bullets were not damaged during the feeding cycle." Black Rifle II, by Christopher R. Bartocci, Chapter Four, Special Operations Command (SOCOM) Variations, Page 110. ETA: I asked about this in the ammo forum and the BS meter hit maximum. The Black Rifle II is not necessarily a good source for reliable information, so we need a reliable source to confirm this before it is accepted as fact. For now, treat it as probable BS. |

|

|

Wow. That's a new one to me. I always thought it was a full auto thing, because that's all I've ever heard here, and it makes sense to me. That, OTH, doesn't quite click in my thick head. I shoot 69gr and 77gr SMKs out of nonramped rifles just fine. |

|

|

|

|

the ramps predate the 77 gr loads.

the answer you seek is on page 70 of TBRII |

|

|

|

Is it possible the thin-jacketed 77gr bullets are only damaged during full-auto fire? Since the increased weight of the 62gr bullet is cited as slowing it down enough that it did not have time to enter one of the feed ramps (hence requiring the modifications), would it not be a worse case with the 77gr bullets? Perhaps the feed ramps are added on SBR rifles for this reason, but are not required for 62gr bullets (because the buffer, bolt velocity, etc., are rifle type, they do not cause the problems they do in the M4). |

|

|

|

Sierra Match Kings have very durable jackets in almost all calibers -- it's what makes them exceptionally tolerant of a wide range of barrel throat lengths. Most will tolerate "Jump" well because of those jackets (they can take a good amount of "Free-bore" jump from their neck seating before hitting rifling engraving).

The M4 "Ramps," especially with jacketed softpoints and hollowpoints was so the actual rough tip edges didn't hang up in the juncture between the top of the upper and the barrel extension. You get the same effect by just rounding off and polishing the first ramp contact point in the barrel extension without having to be as aggressive as Colt's did. When Colt put in the ramps it became a "Commercial proprietary design" not in the US Government technical package, which is why Colt's has the USG by the short hairs and can charge what it does (and can't farm out M4 contracts to others who have held M16 contracts, like FN, GM, etc.). No other M16s have/had it (M16, M16A1, M16A2, M16A4). Remember USSOCOM issues M4A1s exclusively (no more M16A2s or A4s), and besides the AMU and Navy Rifle Teams (perhaps the Marines now that they use MK294) they shoot the most of it. |

|

|

Walk the line at ANY across the course HP match. 99% of the shooters will be running 75-77gr. BTHP(basically MK 262) at 300yd rapid. You'll be lucky to find anyone with M4 feed ramps on the line. No, these aren't maching guns, and there is no one shooting back - but you wont see any alibis due the lack of M4 feedramps. There is no reason for concern if you are shooting 77gr ammo, semi auto from a rifle with a standard barrel extension. |

|

|

|

|

I am sure the M4 ramps were specialy developed for the short BBL carbine in FA. You may never need them in a rifle or a semi auto carbine.

However I find them a "IMPROVMENT" an advanage over the shorter original design. Giving aid to a possable weak mag spring, dirt in mag, or any other thing life can and will through at you, at any given time. |

|

|

|

I have a bushy carbon 15 model 4 that had no feed ramps and initially had some serious feeding problems...so I took my dremel and cut ramps into it...it looks fine (I didn't butcher it, its nice and polished) It feeds fine now. My question is if I want to sell it eventually, how much will that decrease the value if any.

|

|

|

|

Hmmm, lets see here, two Bushmaster 20" rifles, one Olympic M4, and one DPMS M4....M4 ramps present: 0

Misfeeds that were not a result of bad ammo? Zero Misfeeds as a result of bad ammo: </=14 Rounds fired: >10000 Percentage rate of failure: .0014 Clearly M4 feed ramps arent as a big of a deal as people make them out to be. Most times people are saying they have it just for bragging rights. The M16 existed almost 30 years without M4 feed ramps, so it obviously isnt a make or break priority feature |

|

|

|

Anybody aware of somebody who offers a professional service to machine M4 feedramps into your extension/upper without charging an arm & a leg?

|

|

|

Very True - but walk the same line and notice how many M4s you're going to see. Zero. The M4s bolt carrier is moving much faster than the one for the service rifles, hence the magazine spring better be strong to bring the next round up fast enough for the bolt to catch. If you're spring is weakening or there is dirt getting in the magazines (remember there are in combat - not the manicured fields and cement pads of a High Power range) then you can get a condition where the bullet is starting to feed before the nose has cleared the begining of the ramp. I've seen this using worn magazines with my carbines (new magazine spring fixed the problem). I'm sure the problem is more evident with the OTMs, but it can happen with FMJ as well. I don't think the ramps were added for Mk262 as it's been indicated they predated the new round. I agree with Variablebinary they are not a make or break feature, as they fix a problem that is uncommon and can be mostly prevented by using new/good magazines. As civilians we have the luxury of buying new magazines and/or springs when we want; the guys in the field don't have that luxury so the extra insurance for them is a good idea IMHO. |

||

|

|

Thought I'd bump this one back up top. I'd like to know if there's anyone who I can send mine off to have ramps put on upper receiver as well. I know it is easy to do, but I would probably ruin my old Colt upper reciever if I tried. Just don't want to risk it. Thanks for any information. |

|

|

|

If its not broke, dont fix it. JMO. |

||

|

|

Thanks bigbore, you'd be the one to know and give this kind of advise. The reason I was asking is that I am one of the poor guys on this forum who can't afford a new M4 with all of the goodies, not that I'd know what to do with them anyway. I have an old carbine I put together many years ago before M4 ramps and flatops were popular. It's made from an extra AR15 A2 Sporter with fixed A2 carry handle I had. I bought a new Colt 16" barrel and an extra Colt large hole upper with fixed handle, from a member of this forum that is no longer here. He put the upper together for me and checked headspace. The barrel does have the M4 extensions, but the barrel sits more forward inside than my other AR15's leaving a longer "shelf" between where the magazine sits flush with the upper receiver. It has had no problem feeding with what little it gets shot, but I recently discovered that it appears the bullets have been catching on the flat spot in front of the M4 extension on the upper where the M4 upper cuts would be. I noticed one FN magazine that sits lower and it did not allow me to chamber the first round,which has me a little concerned. Any advise ? Thanks |

|

|

|

|

Denny gets it: The M16 system was never ever intended to shoot other than FMJ ammo. That said if you shoot match type ammo with its small hollow point you will experience zero malfuntions due to lack of M4 cuts. Lead exposed tip ammo is not a good idea in any military type weapon, M16s, FALs, G3s etc.

If I feel the need to use hunting/anti-personell ammo I use ballistic tips. They feed 100% due to the plastic tip that does not deform under beating around in the mag or during feeding. Removing the anodizing on the receiver is not a good idea. The upper is aluminum and soft, once you go thru the hard anodizing you expose the aluminum and suject the feed ramp to excessive wear by the ponts of the full metal jacket projos we use most of the time. Let me point out one thing to all the guys grinding the receiver. The BLACK color is not anodizing. Putting Aluminum Black on the fresh cuts you ground is not fixing the problem you created. Anodizing is a surface hardening process. It chemically alters the softer aluminum into harder aluminum oxide. This new surface is more porous, and that allows it to absorb dyes that can color aluminum red, blue, purple, green, gold, or even black. But the color is not the anodizing. I sell anodized products that are the natural aluminum color. The color is something else. So, you just ground through the surface hardening.  If you want M4 ramps, get barrel and upper receiver made with them. But if you are shooting fmj, you just don't need these "M4 Feedramps". |

|

|

|

Newby here with a question...... I'm rebuilding my SBR SWAT gun with a FF system. While my Bushy 11.5 barrel is off the Colt M4 upper I can polish out the barrel ramps a little to match the uppper M4 feed ramps right? I did it once when I put the barrel on but it needs a little more. In FA I get some jams ( about 1 every 200 rds) where the tip of hte FMJ 55gr. sticks into the sharp bottom edge of the barrel ramp. Funny thing is I went two years and 8,000 rounds without a single jam. Last week it started acting up.....@#$%^

A couple passes with my dremel should line them up for good. Any safety issues with this? On a side note I just found AR-15.COM a few weeks ago and I am amazed at what I have learned about my weapon. Thanx much to all the regular's on the site who share their know how and help out a guy in need. |

|

|

|

a lessening of the gas impulse can cause FtF, check your gas rings and the fit of your gas tube to the carrier key.

yes, you can "polish out" the ramps. |

|

|

|

totally forgot about this threat.

I was/am having lots of FTF with my DSC upper and CAV ARMS MKII lower. You can see the copper marks on the upper where they are hitting, right around the spot a ramp should be. Think I found a solution to the problem. |

|

|

Glad you checked in and likely you can and hopefully will contribute to the knowledge base here. Welcome aboard, KAISER!  (we will now continue with our regularly scheduled program- "Clearing Up M4 Feedramp Mis-information") |

|

|

|

If you got copper on your lower, you got bigger problems.

|

|

|

|

|

I though the jacket was made of copper...

ETA: Doh! I meant upper

|

|

|

Even still, you have issues. With everything in spec, bullet tips should be hitting in the lower third of a standard barrel extension feed ramp. If you have copper on your receiver, you've either got mag issues or a out of tolerance issue, which can be a combination of small issues that lead up to one big issue. Remember ARs worked for years without extended ramps. It wasn't until high full auto cyclic rates of carbines started showing real issues with feeding. And this was due to eroded, worn and out-of-spec items as much as anything else. The extended ramps allow more reliable feeding with well used equipment, barrels with eroded (enlarged) gas ports, mags with old and tired springs, lower receivers with worn mag catches, stuff like that. It is, in a sense, a band-aid fix that allows more reliable operation under sever conditions. In reality, it is a product enhancement, not needed for all situations, but nice to have for, say, 0.001% of us. |

|

|

|

|

|

|

|

|

Question, does the bushmaster m-4 style barrel have the m-4 type barrel extension?

Thanks |

|

|

|

one other question, can you grind m4 ramps into the barrel extension...or is that something not recommended...(not recommended by the wescog meathod i mean)

Thanks |

|

|

Why not. RRA does it all the time on their rifles. |

|

|

|

My Bushmaster M4 type does not. It was manufactured during the AWB, don't know the exact year. |

|

|

|

|

one concern,

I'd be grinding an m4 ramp into the barrel extension...with a dremel... I know my hand files don't even dent the barrel extension, i guess its because the barrel extension steel is a lot harder than my file..so my concern is does the dremel have tools to get the job done without changing the hardness of the barrel extension... or do i go reallly slow so as not to change the temper? hinking.gif |

|

|

|

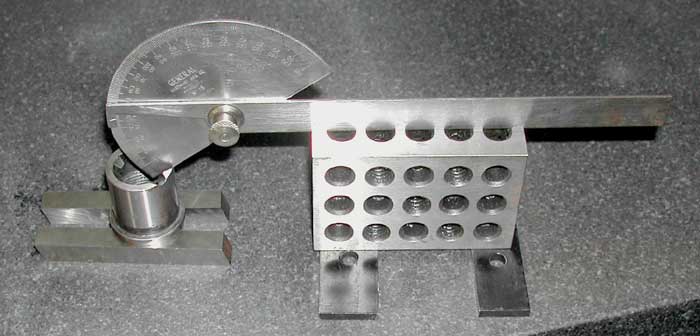

Just for all you would-be ramp modifiers...

During an offline discussion of barrel extensions, it was mentioned that company X used a 38 degree ramp angle. This raised the question "What does a standard feed ramp angle measure?" Well, I took a standard rock river extension and an LMT extension and measured them.  The Standard extension runs 45 to 46 degrees. The M4 extension runs 37 to 38 degrees.  Seeing as how I have standard and M4 barrel extensions in stock, you will never get a dremel-job from me. Randall Rausch www.ar15barrels.com |

|

|

|

NOW, TO ADD TO THE CONFUSION, THERE ARE TWO SUBTLY DIFFERENT "M4 BARREL EXTENSIONS" OUT THERE NOW.

THE GOOD NEWS IS THEY BOTH WORK. WES GRANT M.S.T.N. |

|

|

That's just mean to tickle my interest like that and leave me hanging. I have been using LMT's M4 extensions, so who is the other vendor making them available? It's always good to know all the options. Randall |

|

|

|

|

Just out of idle curiousity, what does it cost to make an upper and extension WITH the M4 ramps, as opposed to WITHOUT?

Maybe an extra $0.005? |

|

|

I pay $1.67 more for an LMT M4 barrel extension than for a standard rifle extension from Rock River Arms. The A4 receivers I use cost exactly the same with M4 ramps as without. I don't charge any more for M4 ramps than regular ramps like some companies do... Randall Rausch www.ar15barrels.com |

|

|

|

|

COMPASS LAKE CHARGES $12 TO CUT M4 FEED RAMPS INTO THEIR STANDARD BARREL EXTENSIONS.

WES GRANT M.S.T.N. |

|

|

|

IMO, all companies should standardize on the extended ramps. It's a product enhancement, but should be standard. Colt would probably sue them, though.

|

|

|

I spoke to Ken Elmer at SAW about this issue and he stated, "Colt actually cut hundreds/thousands of LE Uppers for the new feedramps after anodizing in the late 90's. There will not be any excessive wear." |

|

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.