|

Posted: 10/13/2014 8:34:45 PM EDT

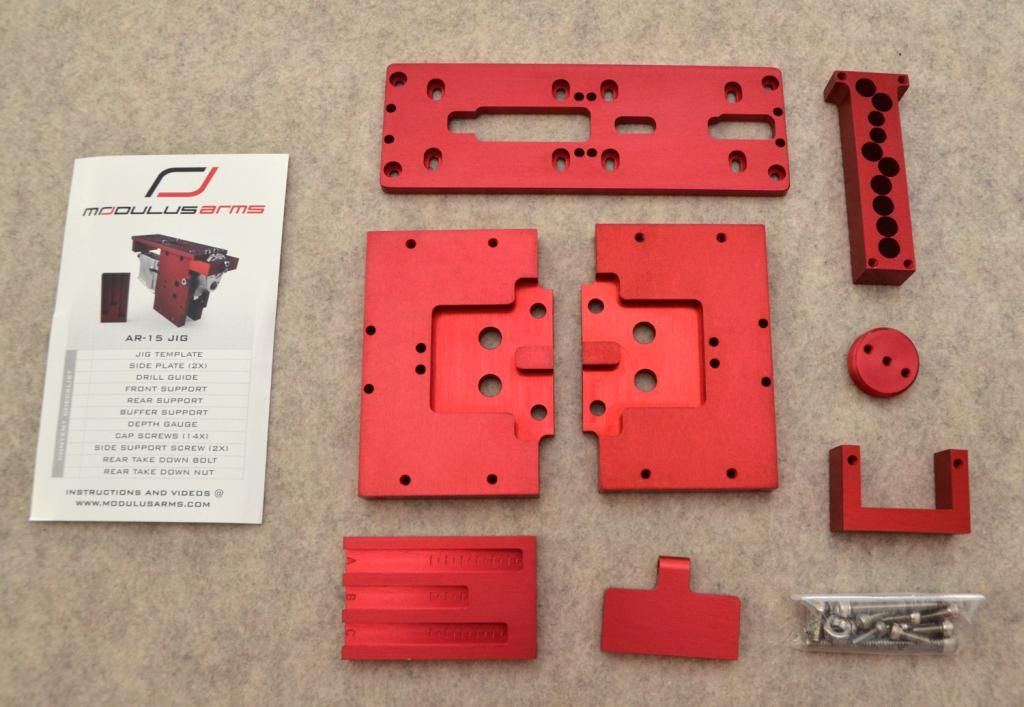

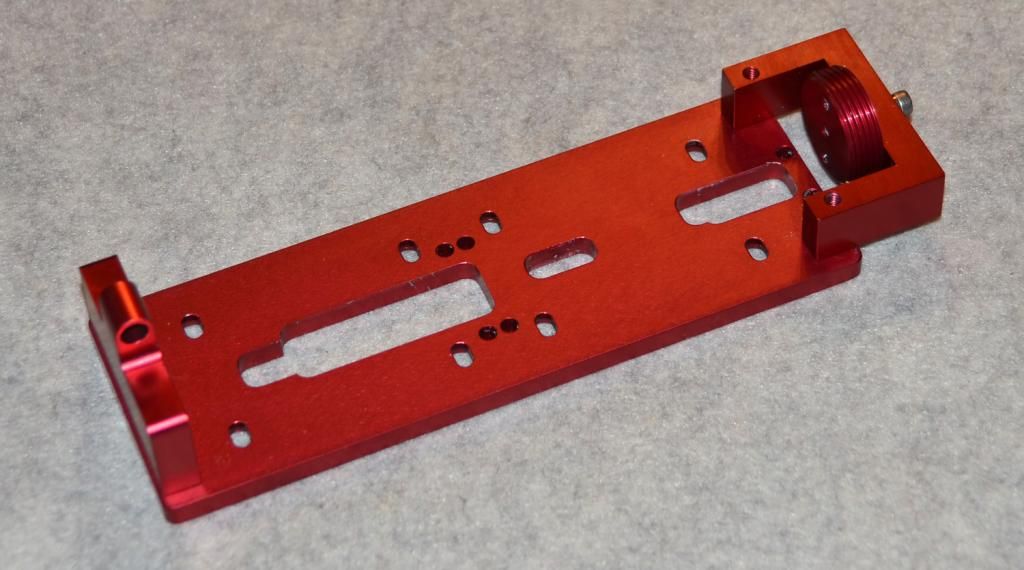

Modulus Arms is new to the 80% lower jig manufacturers. Their Modulus Arms Universal AR-15 80% Lower Receiver Jig is unique in many ways. This is my fourth jig (yeah I know) and I've found that not every lower fits every jig ... until now. Because of the way Modulus Arms jig is designed it appears that they've solved that problem.

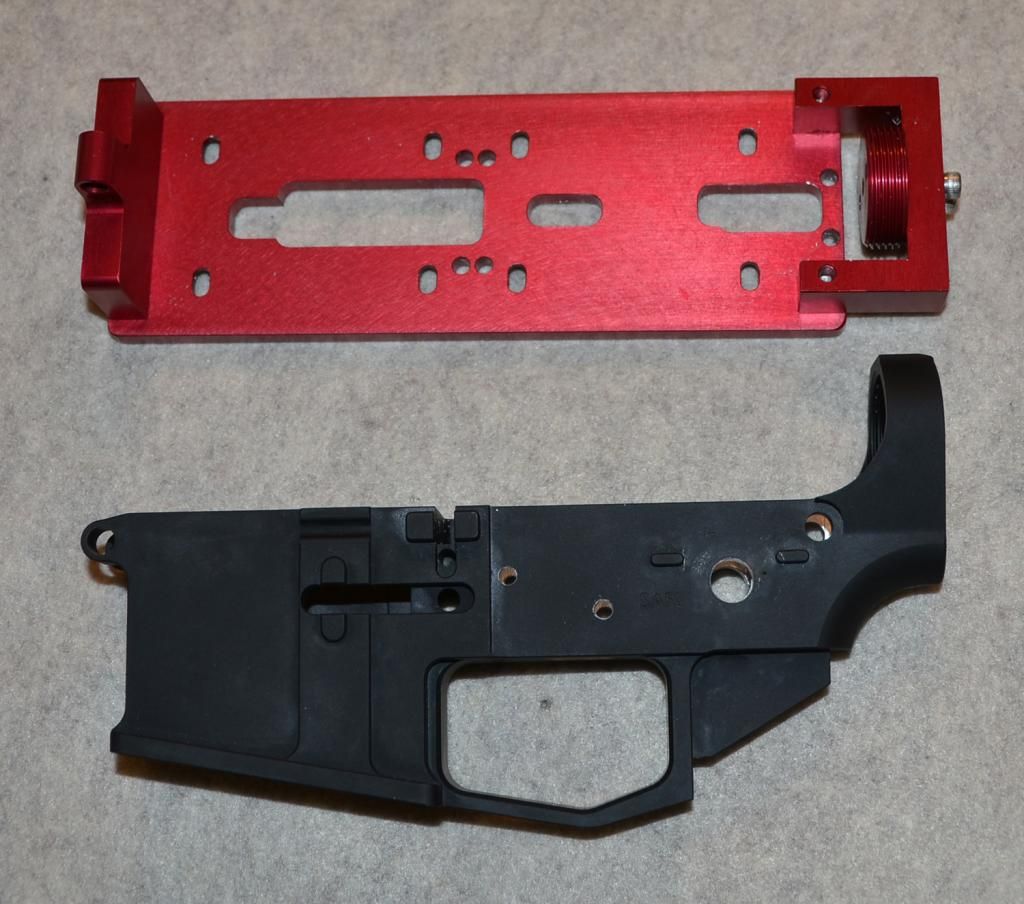

Every 80% AR-15 lower that will work with a standard upper and receiver extension has two points where the upper has to index: the front take down tab and the buffer tube/receiver extension tapped hole.

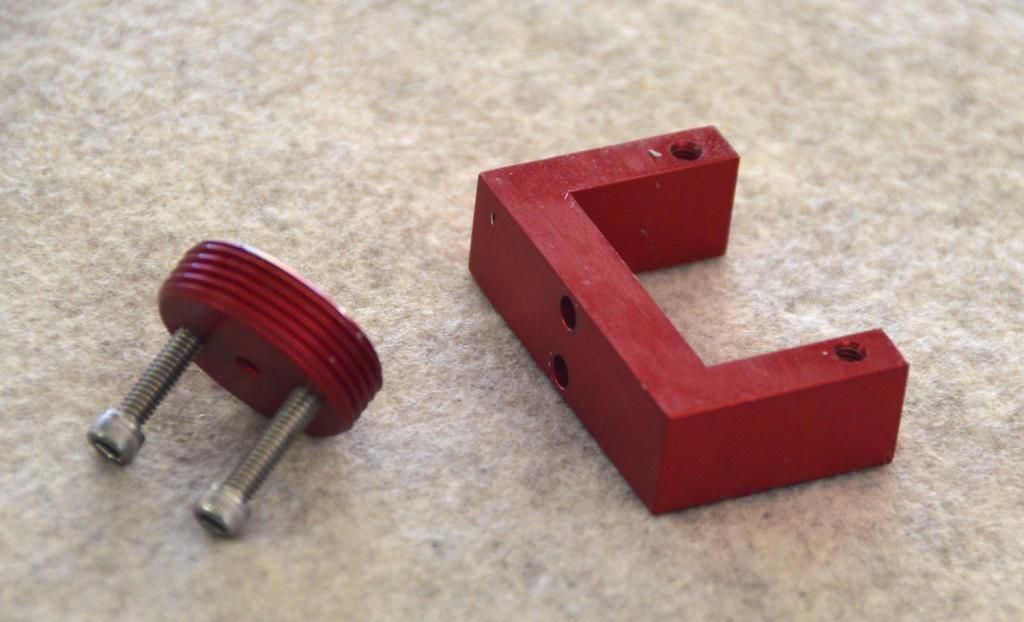

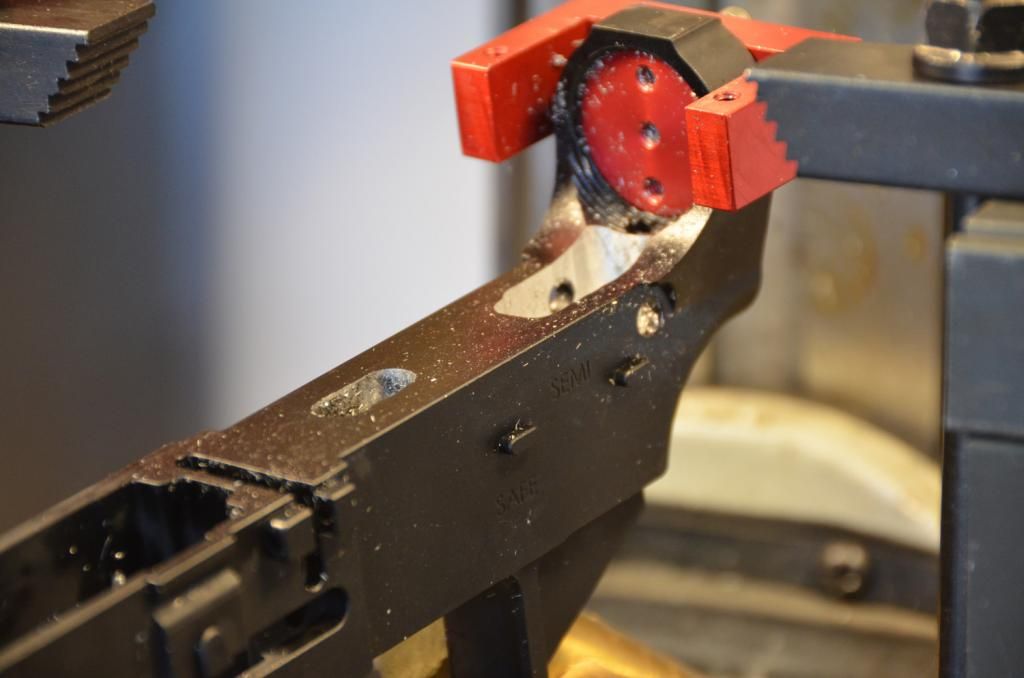

There is a round plug that treads into the buffer tube which allows the jig to index off the rear of the receiver.

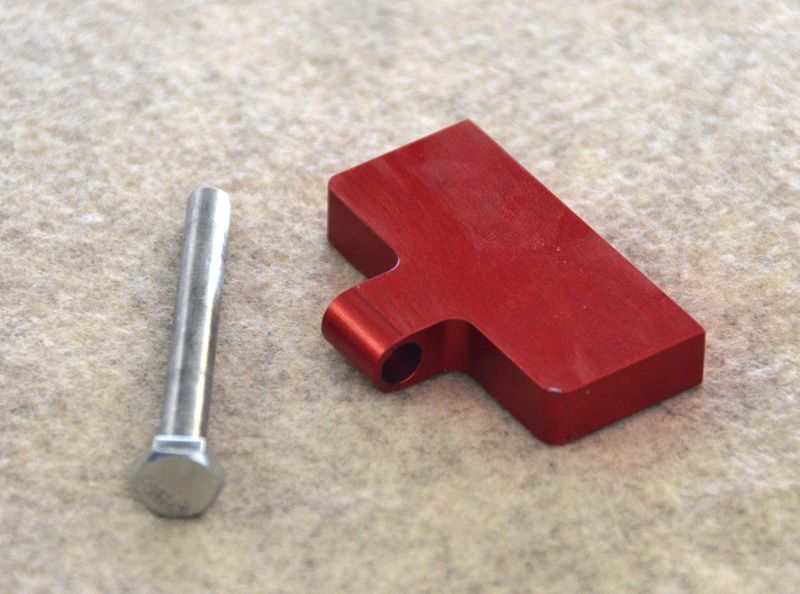

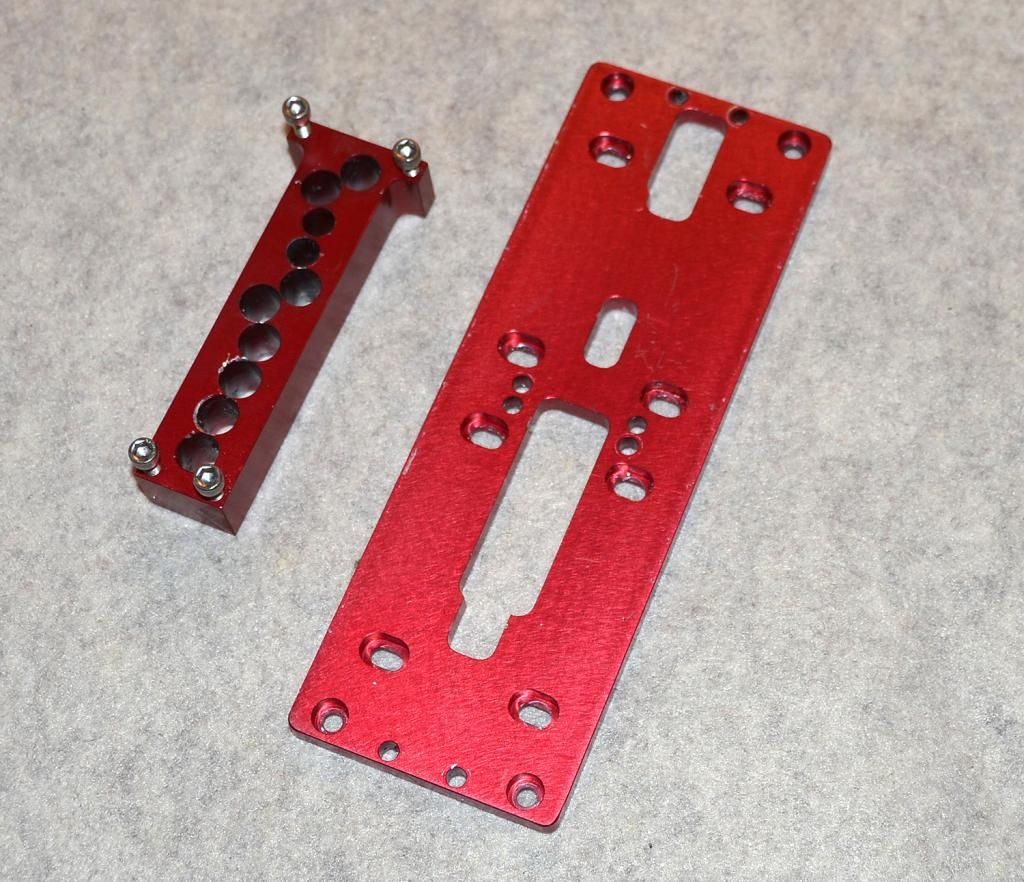

And another jig part that connects into the front take down notch where is it held in place either with the take down pin or with a 1/4" aluminum dowel like I used.

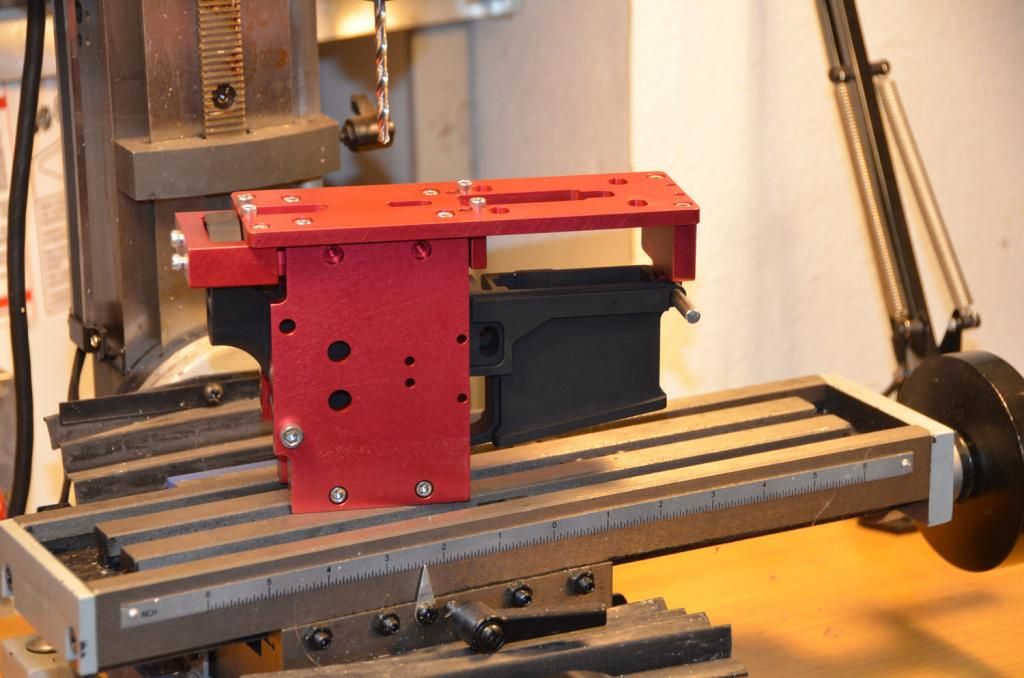

Together these two parts index and hold the cutting jig in place for the three areas that need to be cut - the rear shelf cut to 0.620", the trigger hole cut all the way through, and the main pocket for the trigger cut to 1.249" deep. In the photo below the jig is oriented to cut the first two of those pockets - the rear shelf and the trigger holes. Not shown for clarity are the side supports. To cut the main pocket the top of the jig is unscrewed, rotated 180 degrees and re-attached. A very simple and well thought out system.

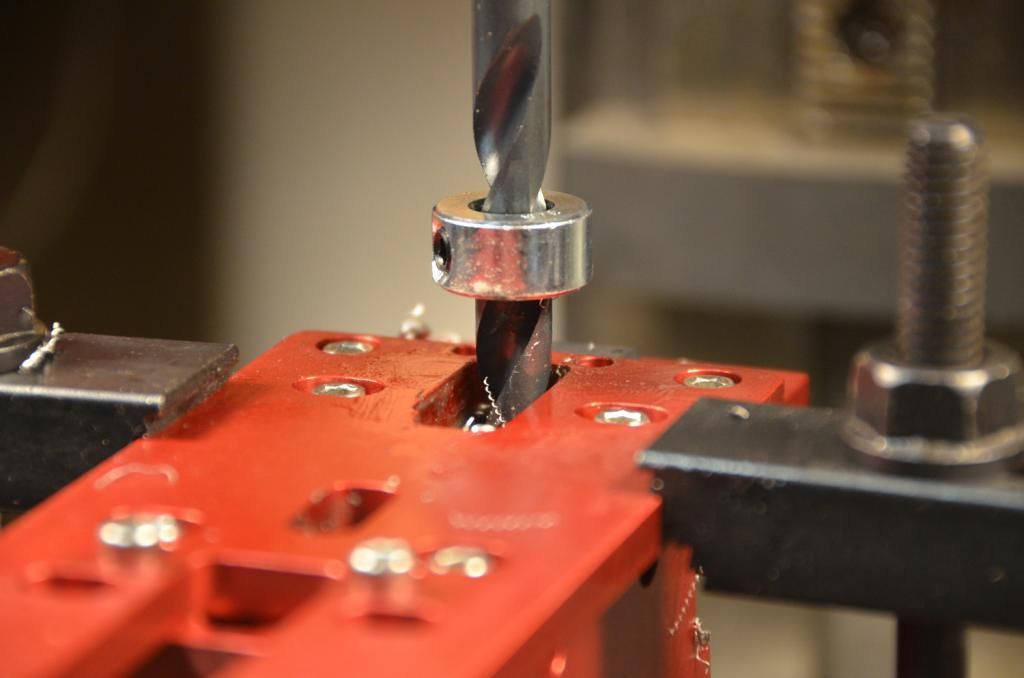

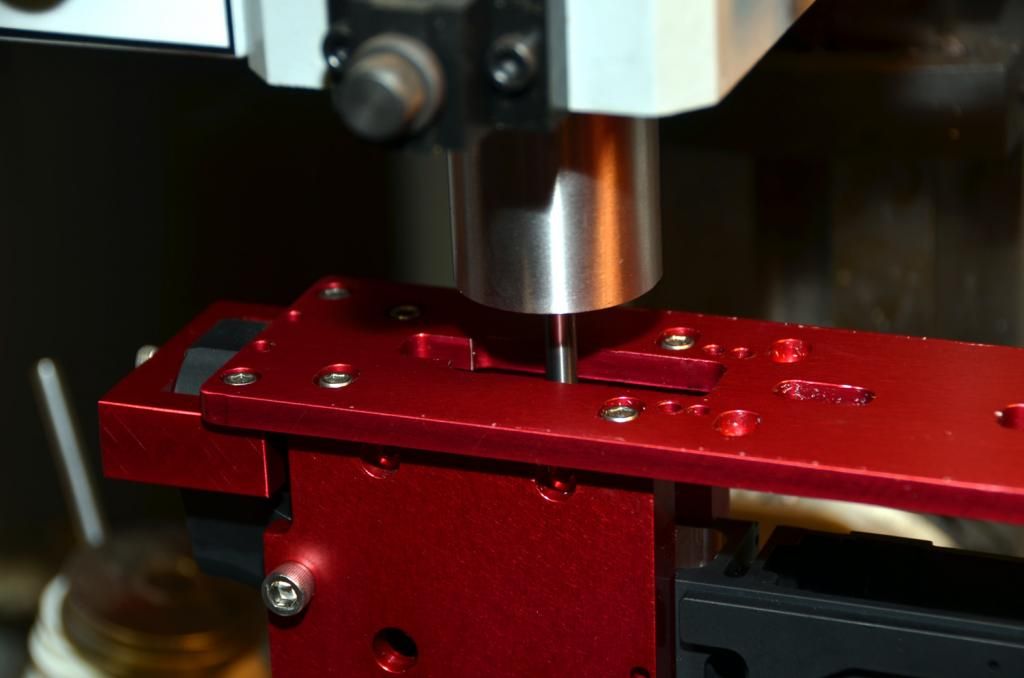

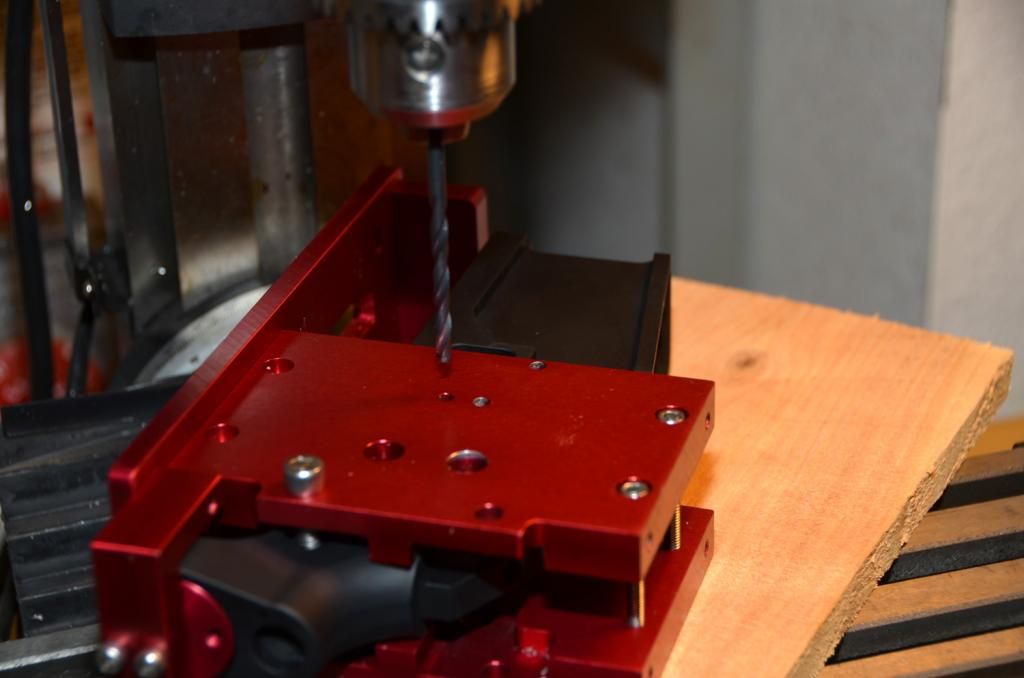

I had a couple of 80% lowers waiting to be finished so I fired up the mini-mill to have at one. The Modulus Arms jig is designed to be completed with a drill/drill press and either using a handheld router or a mill. The top surface is designed to lay a small router up on top and use a 1/4" end mill to complete. I recommend using a variable speed plunge type router if you're going to use ... this route as you'll want to cut with a lower speed on aluminum than crazy wicked speeds of a fixed router and the plunge adjustment will make using the include depth gauge easier. Milling out the pockets is a lot of work on the tool which can be done with a cheaper/faster drill bit. Modulus sells a small kit with the required 1/4" carbide end mill, 3/8" drill bit and drill stop, a 19/64" bit for the trigger hole, and a 5/32" for cutting the trigger and disconnector side holes. Available here. I connected the jig up and drilled out parts of the pockets using the include depth guide. The 3/8" drill stop is used to limit the plunge depth of the drill press.

3/8" holes are cut in the rear for the shelf that the upper drops down against for the take down pin.

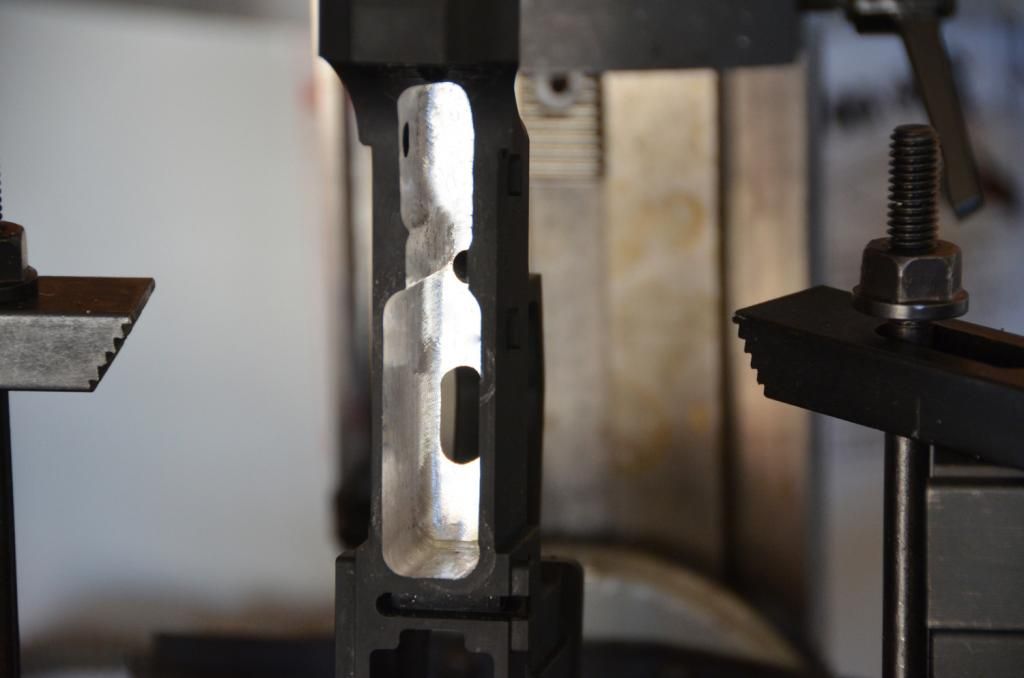

The 19/64" bit cuts the trigger hole all the way down through the bottom of the lower. The milling of the trigger hole is then done. This is different that many other jigs in that the bulk of the pocket material is still there supporting the end mill cutting tool. In some of my lowers when completing the trigger hold with the pocket already cleared the cutting tool wants to cut "outside the lines" as you're using a small 1/4" mill at close to 2" of length. A side view

The result is pretty nice.

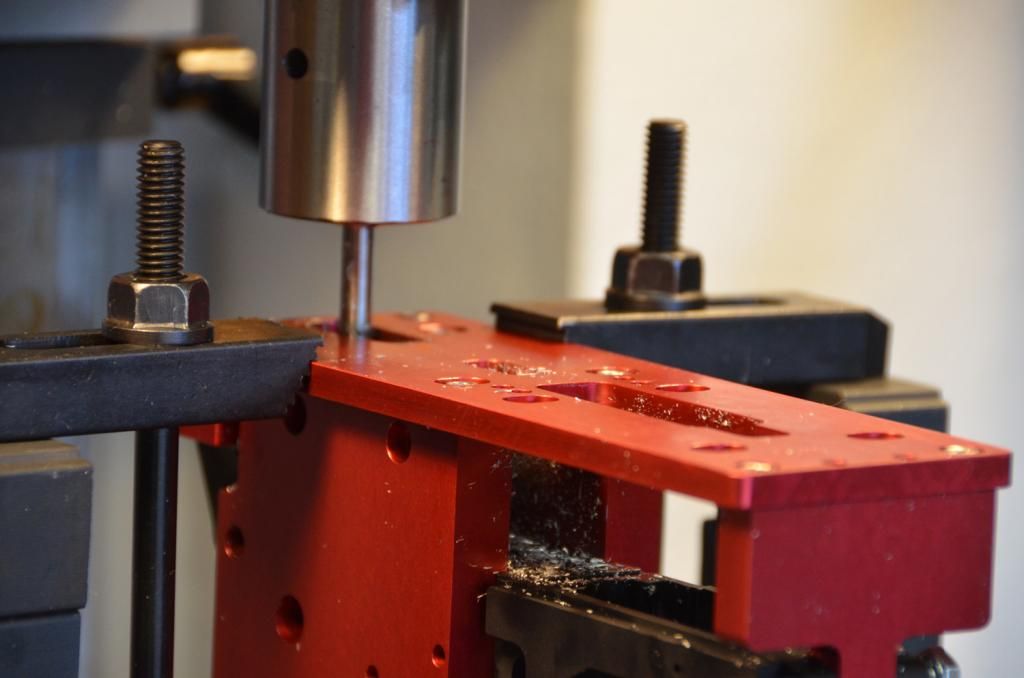

You then mill out the rear shelf. The jig is held up above the surface of the lower which does two important things. First and most importantly it protects the jig from the cutting action of the end mill. Having the tool below the jig's side makes it impossible to nick the jig. Secondly the space allows the swarf a place to gather and pour out so that the work is easier and the upper surface of the lower is protected. In the photo below I've removed the cutting jig to rotate it around for the main pocket work.

And results.

The included drill bit guide mounts under the jig template to guide the 3/8" and 19/64th holes. Starting and stopping the drill press while inside the holes protects the guide from getting cut up too badly. The jig includes all the needed cap screws.

Making lots of chips with the drill saves the wear and tear on the end mill tool.

Milling is done with a 1/4" end mill.

After a bit of milling out pops a completed fire control pocket.

Another unique feature of the jig is that the safety/selector, trigger pin, and disconnector pin holes on the jigs side are provided twice - there's a set on top and rotating the left to right side and flipping them over the bottom pair can be used as well. That's a pretty neat feature.

The results look very nice.

The Modulus Arms web site indicates that they're working on a .308 upper. This jig solves the issue of having to match your jig to your 80% lower. It can be done simple tools like a drill press and a handheld variable speed plunge router or a mini mill. The fit and finish of the jig is top notch and shows that the designer has thought out the 80% completion process completely. I can most highly recommend this jig. |

|

|

Celebrating the Second Amendment One Fine Firearm at a Time

|

|

Excellent review Paul! The pros you highlighted were some of the primary reasons I bought one of these. It's a very well thought out design.

|

|

|

|

|

...believe in me, I'm with the High Command.

|

The only issue I see with it is that it doesn't locate the bolt catch plunger hole, Anderson Arms has been shipping 80% lowers that are not drilled for the bolt catch plunger. (I have two)

|

|

"When trading bullets it is better to give than to receive"

"Take your money and a traveler's bag. And if you don't have a sword, sell your clothes and buy one!" Jesus Christ - Luke 22.36 NRA Endowment Member |

|

OST. Looks like this is the route I want to go

Thanks OP!

|

|

|

The government cannot give to anyone anything that it does not first take from someone else.

|

|

Originally Posted By PursuitSS:

The only issue I see with it is that it doesn't locate the bolt catch plunger hole, Anderson Arms has been shipping 80% lowers that are not drilled for the bolt catch plunger. (I have two) View Quote Yikes. I'd have to look at my jigs but I think only my 1998 era Tannery had that feature as those "80%" lowers were closer to what we call 40% ... of course back then we didn't have electric motors and the lowers were made out of stone ... I'll have to pull out my other jigs to see if they index the bolt catch plunger. |

|

|

Celebrating the Second Amendment One Fine Firearm at a Time

|

|

That turned out really good. Mine using the router was not as nice but still GTG. I really like these jigs.

My only thoughts for improvement would be having more holes to drill out. I understand this takes more time but I think having a little more material removed with a drill would help when using a router. Wont matter for a actual mill. It still works very well IMHO. |

|

|

|

|

Originally Posted By Paul:

Yikes. I'd have to look at my jigs but I think only my 1998 era Tannery had that feature as those "80%" lowers were closer to what we call 40% ... of course back then we didn't have electric motors and the lowers were made out of stone ... I'll have to pull out my other jigs to see if they index the bolt catch plunger. View Quote View All Quotes View All Quotes Originally Posted By Paul:

Originally Posted By PursuitSS:

The only issue I see with it is that it doesn't locate the bolt catch plunger hole, Anderson Arms has been shipping 80% lowers that are not drilled for the bolt catch plunger. (I have two) Yikes. I'd have to look at my jigs but I think only my 1998 era Tannery had that feature as those "80%" lowers were closer to what we call 40% ... of course back then we didn't have electric motors and the lowers were made out of stone ... I'll have to pull out my other jigs to see if they index the bolt catch plunger. IMO, the bolt catch plunger is something most people can just WECSOG with a well calibrated eye ball. |

|

|

|

|

Based on this excellent writeup I just ordered one of these jigs...

I have a drill press (from Harbor Freight so its not the best in the world but it is one of the better ones they sell), and an old Craftsman router... but do y'all think I can do a decent job with those tools or should I really shell out the $500 or so to buy a benchtop end mill? Or could I get by just buying a variable speed plunge router? |

|

|

|

|

Nice review. I am a rookie at working with firearms, but I do have a milling machine and a decent drill press.

What bothers me is that I had to look up what WECSOG. Roy |

|

|

|

|

Originally Posted By SoftwareJanitor:

Based on this excellent writeup I just ordered one of these jigs... I have a drill press (from Harbor Freight so its not the best in the world but it is one of the better ones they sell), and an old Craftsman router... but do y'all think I can do a decent job with those tools or should I really shell out the $500 or so to buy a benchtop end mill? Or could I get by just buying a variable speed plunge router? View Quote I've made a couple of lowers using a drill press ... but that was before the jig science changed allowing us the ability to use a router. The drill press is designed to do vertical up-n-down work. The bit is designed to be pushed down into the work. With a router (and of course the mill) the work is designed to be pressed sideways into the tool - this is what we're doing for the majority of the work on the fire control pocket. Because of the difference the router/mill has less slop side-to-side than an equal drill press. If I didn't have my mill I'd rent a variable speed plunge router at the local Home Depot for the day. You could likely finish several lowers in that time. |

|

|

Celebrating the Second Amendment One Fine Firearm at a Time

|

|

I guess I'm going to have to get one of these and my next build will be from an 80% lower. Damn! I've been bitten by the build bug!

|

|

|

|

|

Originally Posted By SoftwareJanitor:

Based on this excellent writeup I just ordered one of these jigs... I have a drill press (from Harbor Freight so its not the best in the world but it is one of the better ones they sell), and an old Craftsman router... but do y'all think I can do a decent job with those tools or should I really shell out the $500 or so to buy a benchtop end mill? Or could I get by just buying a variable speed plunge router? View Quote You don't need a plunge router. You need a variable speed laminate router like a Bosch PR20EVSK or similar. |

|

|

|

|

Originally Posted By charliehorse1967:

I guess I'm going to have to get one of these and my next build will be from an 80% lower. Damn! I've been bitten by the build bug! View Quote They're like potato chips ... once you do one ... you do another and another ... serial numbers are so overrated. |

|

|

Celebrating the Second Amendment One Fine Firearm at a Time

|

|

Nice write up.

|

|

|

Only two defining forces have ever offered to die for you,

Jesus Christ and the American Soldier. One died for your soul; the other for your freedom. George Patton |

|

Nice, informative review. Much appreciated...

|

|

|

|

|

Nice write up and that's a very clever jig. Did you consider not connecting the two wells?

|

|

|

Managing Member of Mischief

|

|

Celebrating the Second Amendment One Fine Firearm at a Time

|

|

Originally Posted By Paul:

I've seen lowers like that ... weren't those designed to prevent the use of a lighting link or something? View Quote View All Quotes View All Quotes Originally Posted By Paul:

Originally Posted By backbencher: Nice write up and that's a very clever jig. Did you consider not connecting the two wells? I've seen lowers like that ... weren't those designed to prevent the use of a lighting link or something? They do that - but by leaving the material in place, it strengthens the receiver marginally. Just wondered if you'd considered doing so - given your rate of production. |

|

|

Managing Member of Mischief

|

|

I think the amount of structure it adds is negligible. It does remove a little bit of weight too.

|

|

|

|

|

Originally Posted By SSCamaro:

You don't need a plunge router. You need a variable speed laminate router like a Bosch PR20EVSK or similar. View Quote View All Quotes View All Quotes Originally Posted By SSCamaro:

Originally Posted By SoftwareJanitor:

Based on this excellent writeup I just ordered one of these jigs... I have a drill press (from Harbor Freight so its not the best in the world but it is one of the better ones they sell), and an old Craftsman router... but do y'all think I can do a decent job with those tools or should I really shell out the $500 or so to buy a benchtop end mill? Or could I get by just buying a variable speed plunge router? You don't need a plunge router. You need a variable speed laminate router like a Bosch PR20EVSK or similar. 15000 - 35000 rpm? Isn't that too fast for milling? |

|

|

|

|

Originally Posted By SoftwareJanitor:

15000 - 35000 rpm? Isn't that too fast for milling? View Quote I believe the Modulus arms manual says they did their lowers at around 24,000 rpm. I've done a couple with my router at 25000 and I got a little clatter, so I may try to slow it down a little on my next lower. |

|

|

|

|

That is the one they recommend in the instructions.

http://www.modulusarms.com/content/AR-15%20Jig%20Instructions%20ver%201.7.pdf |

|

|

|

|

Thanks Paul. Currently I have 1 80% and I am looking at different jigs. This one sounds great. The nice part about it is, that if this project turns out well, I plan on doing more and using different lower manufacturers. I don't have any machines, but my buds dad owns a machine shop and has mills. I will be doing all the work myself, but it would be nice to use his equipment. I could probably do it without a jig at the machineshop or is that a huge undertaking that requires years of machine shop experience? |

|

|

|

|

Add drill bushings and you've got my money.

|

|

|

|

|

Originally Posted By OverScoped:

Thanks Paul. Currently I have 1 80% and I am looking at different jigs. This one sounds great. The nice part about it is, that if this project turns out well, I plan on doing more and using different lower manufacturers. I don't have any machines, but my buds dad owns a machine shop and has mills. I will be doing all the work myself, but it would be nice to use his equipment. I could probably do it without a jig at the machineshop or is that a huge undertaking that requires years of machine shop experience? View Quote I've chased 'trons all my life ... not turned wrenches. I am not a machinist by any measure. You're about 99% likely to complete the lower good enough that it will work ... about 97% to do it flawlessly. I've now made more than a handful of 80% lowers and only had issues with my first one back in 1998 when those lowers required drilling out all holes - including finishing the magazine well (uggh!) and the buffer extension hole. Using today's 80% lowers and a jig like this one you're going to have to work hard to not get it finished correctly. The best feature of this jig is that it's design is "outside-the-box" in that it indexes (and holds) the 80% differently. The thickness of the side walls (the width measurement of the lower) varies a bit as does the design of the magwell flare and trigger guard (some have them others don't). The Modulus Arms grips the points where the industry standard upper meets the lower. You then attach the side walls - there's a bit of movement allowed until locked down to allow for different width lowers - index the rear take down pin (EXCEPT WHILE MILLING THE REAR POCKET!!) and tighten up. The nice thing about doing the work at your friends shop is that they're good tools there to use. There are wonderful videos on the Modulus Arms site and following them step-by-step makes it easy to complete. A good machine shop is going to have the vice to clamp the work solid, cutting fluid, and a good mill. I cut aluminum at 1250 RPM and use a cutting fluid to keep things cool. |

|

|

Celebrating the Second Amendment One Fine Firearm at a Time

|

|

Originally Posted By Paul: I've chased 'trons all my life ... not turned wrenches. I am not a machinist by any measure. You're about 99% likely to complete the lower good enough that it will work ... about 97% to do it flawlessly. I've now made more than a handful of 80% lowers and only had issues with my first one back in 1998 when those lowers required drilling out all holes - including finishing the magazine well (uggh!) and the buffer extension hole. Using today's 80% lowers and a jig like this one you're going to have to work hard to not get it finished correctly. The best feature of this jig is that it's design is "outside-the-box" in that it indexes (and holds) the 80% differently. The thickness of the side walls (the width measurement of the lower) varies a bit as does the design of the magwell flare and trigger guard (some have them others don't). The Modulus Arms grips the points where the industry standard upper meets the lower. You then attach the side walls - there's a bit of movement allowed until locked down to allow for different width lowers - index the rear take down pin (EXCEPT WHILE MILLING THE REAR POCKET!!) and tighten up. The nice thing about doing the work at your friends shop is that they're good tools there to use. There are wonderful videos on the Modulus Arms site and following them step-by-step makes it easy to complete. A good machine shop is going to have the vice to clamp the work solid, cutting fluid, and a good mill. I cut aluminum at 1250 RPM and use a cutting fluid to keep things cool. View Quote View All Quotes View All Quotes Originally Posted By Paul: Originally Posted By OverScoped: Thanks Paul. Currently I have 1 80% and I am looking at different jigs. This one sounds great. The nice part about it is, that if this project turns out well, I plan on doing more and using different lower manufacturers. I don't have any machines, but my buds dad owns a machine shop and has mills. I will be doing all the work myself, but it would be nice to use his equipment. I could probably do it without a jig at the machineshop or is that a huge undertaking that requires years of machine shop experience? I've chased 'trons all my life ... not turned wrenches. I am not a machinist by any measure. You're about 99% likely to complete the lower good enough that it will work ... about 97% to do it flawlessly. I've now made more than a handful of 80% lowers and only had issues with my first one back in 1998 when those lowers required drilling out all holes - including finishing the magazine well (uggh!) and the buffer extension hole. Using today's 80% lowers and a jig like this one you're going to have to work hard to not get it finished correctly. The best feature of this jig is that it's design is "outside-the-box" in that it indexes (and holds) the 80% differently. The thickness of the side walls (the width measurement of the lower) varies a bit as does the design of the magwell flare and trigger guard (some have them others don't). The Modulus Arms grips the points where the industry standard upper meets the lower. You then attach the side walls - there's a bit of movement allowed until locked down to allow for different width lowers - index the rear take down pin (EXCEPT WHILE MILLING THE REAR POCKET!!) and tighten up. The nice thing about doing the work at your friends shop is that they're good tools there to use. There are wonderful videos on the Modulus Arms site and following them step-by-step makes it easy to complete. A good machine shop is going to have the vice to clamp the work solid, cutting fluid, and a good mill. I cut aluminum at 1250 RPM and use a cutting fluid to keep things cool. |

|

|

|

|

Celebrating the Second Amendment One Fine Firearm at a Time

|

|

|

|

The sides have 2x the holes and can be flipped over so the drill bushings aren't needed. You get two for one with the sides.

|

|

|

|

|

Hey Paul, I've noticed in several of your photo threads, you seem to use the clamp kit instead of a mill vise. Is that because you have limited z-axis travel or do you just prefer the clamp kit?

I am close to pulling the trigger on a mini-mill and wonder if a mill vise is money needlessly spent. |

|

|

|

|

my jig came in.

Looks like my brother and BIL will be doing the first ever 80% So we will have 3 different lowers on this jig. Standard forged One Billet and a plastic from ares that I will be making into a light weight 22. We will be using a router |

|

|

Only two defining forces have ever offered to die for you,

Jesus Christ and the American Soldier. One died for your soul; the other for your freedom. George Patton |

|

How difficult would it be to make a working wooden lower with this jig?

|

|

|

Managing Member of Mischief

|

|

Originally Posted By uxo2:

my jig came in. Looks like my brother and BIL will be doing the first ever 80% So we will have 3 different lowers on this jig. Standard forged One Billet and a plastic from ares that I will be making into a light weight 22. We will be using a router View Quote Post results! |

|

|

|

|

|

|

Originally Posted By Bretshooter:

Post results! View Quote View All Quotes View All Quotes Originally Posted By Bretshooter:

Originally Posted By uxo2:

my jig came in. Looks like my brother and BIL will be doing the first ever 80% So we will have 3 different lowers on this jig. Standard forged One Billet and a plastic from ares that I will be making into a light weight 22. We will be using a router Post results! You bet |

|

|

Only two defining forces have ever offered to die for you,

Jesus Christ and the American Soldier. One died for your soul; the other for your freedom. George Patton |

|

...believe in me, I'm with the High Command.

|

|

|

"When trading bullets it is better to give than to receive"

"Take your money and a traveler's bag. And if you don't have a sword, sell your clothes and buy one!" Jesus Christ - Luke 22.36 NRA Endowment Member |

|

Originally Posted By PursuitSS:

It probably would look better than this one does.... http://i135.photobucket.com/albums/q125/PursuitSS/52313d0f74d80eaa768c21f6c50572f7.jpg View Quote View All Quotes View All Quotes Originally Posted By PursuitSS:

Originally Posted By backbencher: How difficult would it be to make a working wooden lower with this jig? It probably would look better than this one does.... http://i135.photobucket.com/albums/q125/PursuitSS/52313d0f74d80eaa768c21f6c50572f7.jpg True - Orion's Hammer recommends not repeating his experiment in pine. But it did fire 3 shots. |

|

|

Managing Member of Mischief

|

|

awesome write up. I had seen these billed as universal jigs and really wondered how that could be. once I saw how it worked I thought it was very slick. now seeing you put it to the test has really sold me. I only have like 10 blanks on order that will need to be done....

I do wonder about drilling the side holes. it has usually been advised to drill these prior to doing the FCG pocket due to flex/deflection in the long and thin drill bit. with this jig though each side is a separate process, so less chance of this happening. there could be a bit of a chance to have misalignment from side to side though. Paul, would you see any advantage/disadvantage do drilling these holes before doing the FCG, or do you think it is accurate enough to not worry about it? |

|

|

|

|

Any thoughts as to using one size smaller drill bit and a reamer, instead of the "hole-size" drill bit?

Wasn't sure if that would better protect the edges of the jig, for those like me who are twitchy amateurs with power tools. Having just ordered this nice jig, I'd hate to screw it up when a couple bucks for another tool would be wise. |

|

|

|

|

...believe in me, I'm with the High Command.

|

Originally Posted By XJ:

Any thoughts as to using one size smaller drill bit and a reamer, instead of the "hole-size" drill bit? Wasn't sure if that would better protect the edges of the jig, for those like me who are twitchy amateurs with power tools. Having just ordered this nice jig, I'd hate to screw it up when a couple bucks for another tool would be wise. View Quote Roseville has .154 holes BUT, their website has issues. I'm wondering if they are gone. LINK |

|

"When trading bullets it is better to give than to receive"

"Take your money and a traveler's bag. And if you don't have a sword, sell your clothes and buy one!" Jesus Christ - Luke 22.36 NRA Endowment Member |

|

Originally Posted By XJ:

Any thoughts as to using one size smaller drill bit and a reamer, instead of the "hole-size" drill bit? Wasn't sure if that would better protect the edges of the jig, for those like me who are twitchy amateurs with power tools. Having just ordered this nice jig, I'd hate to screw it up when a couple bucks for another tool would be wise. View Quote great idea. I am worried about enlarging the holes in the jig side plates with as many pieces I have to work on (10 right now, and Im sure some friends will want to do so as well. I could see one jig being used for 20 receivers). I was contemplating installing drill bushings but this might be a better way to go. |

|

|

|

|

Originally Posted By SSCamaro:

You don't need a plunge router. You need a variable speed laminate router like a Bosch PR20EVSK or similar. View Quote View All Quotes View All Quotes Originally Posted By SSCamaro:

Originally Posted By SoftwareJanitor:

Based on this excellent writeup I just ordered one of these jigs... I have a drill press (from Harbor Freight so its not the best in the world but it is one of the better ones they sell), and an old Craftsman router... but do y'all think I can do a decent job with those tools or should I really shell out the $500 or so to buy a benchtop end mill? Or could I get by just buying a variable speed plunge router? You don't need a plunge router. You need a variable speed laminate router like a Bosch PR20EVSK or similar. I can't find anyone local that has that Bosch in stock, so I just bought a Makita RT0701C which seems to have similar specs to the Bosch. From what I've heard over the years Makita has a fairly good reputation for quality and the one I got actually has more power (1.25 HP vs. 1.0 HP) and wider speed adjustability (10,000 RPM - 30,000 RPM vs. 16,000 RPM - 35,000 RPM) with more of the range to the slower side, the other specs like the size and collet capacity are the same or similar. Hopefully this one will work out good. I didn't have a lot of choice the Makita was about the only thing I could find that looked similar to the Bosch. |

|

|

|

|

If you have a milling machine you don't need a jig of any kind. You just need a print there are many on the net available for free so don't pay for one keep looking. You don't need a CNC machine unless you are going to production. Learn to operate your milling machine and it will look better and be more accurate than any jig.

|

|

|

|

|

Paying all the money for a Monulus arms Jig it would come with a Drill bushings. If they would start installing them I would buy one.

|

|

|

|

|

Originally Posted By Lawdog-1:

Paying all the money for a Monulus arms Jig it would come with a Drill bushings. If they would start installing them I would buy one. View Quote If they added drill bushings to the Modulus jig it would probably increase the price significantly. You don't really need bushings, especially if you've got a decent drill press and good, sharp drill bits. |

|

|

|

|

Originally Posted By SoftwareJanitor:

If they added drill bushings to the Modulus jig it would probably increase the price significantly. You don't really need bushings, especially if you've got a decent drill press and good, sharp drill bits. View Quote View All Quotes View All Quotes Originally Posted By SoftwareJanitor:

Originally Posted By Lawdog-1:

Paying all the money for a Monulus arms Jig it would come with a Drill bushings. If they would start installing them I would buy one. If they added drill bushings to the Modulus jig it would probably increase the price significantly. You don't really need bushings, especially if you've got a decent drill press and good, sharp drill bits. I have had no issues and it seems like OP did well without them |

|

|

Only two defining forces have ever offered to die for you,

Jesus Christ and the American Soldier. One died for your soul; the other for your freedom. George Patton |

|

Originally Posted By uxo2:

I have had no issues and it seems like OP did well without them View Quote View All Quotes View All Quotes Originally Posted By uxo2:

Originally Posted By SoftwareJanitor:

Originally Posted By Lawdog-1:

Paying all the money for a Monulus arms Jig it would come with a Drill bushings. If they would start installing them I would buy one. If they added drill bushings to the Modulus jig it would probably increase the price significantly. You don't really need bushings, especially if you've got a decent drill press and good, sharp drill bits. I have had no issues and it seems like OP did well without them Most other brands of jig besides Modulus don't include them either... I've only seen a couple that do. |

|

|

|

|

I think adding drill bushings would probably increase the number of times you could reuse the jig by quite a bit though. Why not make them out of steel to begin with?

Still looks to be the best jig out there though. I've been saving up my mad money to try one of these myself with a 80% forged lower. Just acquiring tools and materials that I'll need right now. Mainly gonna do it because it looks fun and interesting. Then I guess I'll have to try their jig for the .308 lowers. In the future I hope they'll do other universal jigs for 1022's, 1911's, a wide body style of 1911 (ala Paraordnance for example), maybe a shotgun jig, etc. |

|

|

|

|

I just bought one today. great price too. |

|

|

|

|

Originally Posted By BroadSideOfADime:

Hey Paul, I've noticed in several of your photo threads, you seem to use the clamp kit instead of a mill vise. Is that because you have limited z-axis travel or do you just prefer the clamp kit? I am close to pulling the trigger on a mini-mill and wonder if a mill vise is money needlessly spent. View Quote My mill has the extended height modification but still I'd rather clamp the jig directly to the table. A mill vice big enough to hold the jig is going to be a big (expensive) one. The clamp kit is cheap and locks tightly - the only negative is ensuring that you've got the lower aligned correctly before locking it down and I use a series of mill squares to square the jig before tightening everything down. |

|

|

Celebrating the Second Amendment One Fine Firearm at a Time

|

|

...believe in me, I'm with the High Command.

|

I have been looking into adding Drill Bushings to this jig.

I've found a source for Tungsten Carbide Drill Bushings and I can get bushings for the trigger and hammer holes that have an I.D. Of .154 |

|

"When trading bullets it is better to give than to receive"

"People sleep peaceably in their beds at night only because rough men stand ready to do violence on their behalf." - George Orwell |

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.