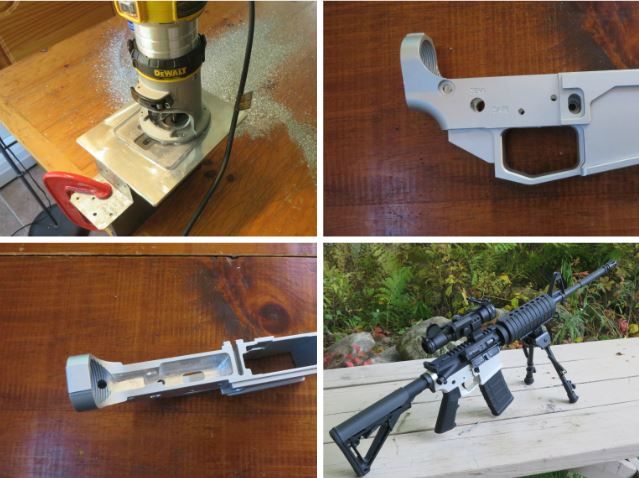

I had drafted a detailed review of my exp. with 80% Arms Easy Jig, as well as, their lower receiver. Sadly, new members have a 2000 char. limit here. With that being said, here's a summary:

Some things I was specifically interested in:

1.Easy

2.Reliable

3.Ability to complete work with only the use of simple tools. (no drill presses, mills, lathes, cnc, etc.)

4.Good instruction

5.Solid customer service.

In the end, I opted for 80% Arms.

Less than 2 days later I had an 80% Arms Easy Jig, and stripped 80% lower (non-anodized).

In my endeavors, I came across a video where this guy had completed a jig on a flimsy table w/ a drill, a POS router, and a C-clamp. His results, near perfect. To me, that was PRECISELY what I was looking for, and I found it with 80% Arms.

PROS:

1. Great Customer Service (as illustrated by their staff here on the forums). *Also, thanks Jeff!!

2. It's Easy. REALLY Easy!

3. Superb Results.

4. Good Instruction/Ref's. (eg. vid. and tech doc).

CONS:

1. Anodizing of parts was a tad sloppy (this has ZERO impact on overall quality/functionality)

2. Threads on right plate (top) not well fabricated. (still functional)

FINAL REMARKS – It's a newer company, with a fairly newer product line. With that being said, it may not contain the 'flare' of a company conditioned over a 50 year existence. Although, it's quite obvious that they believe in their product, and are COMMITTED to making the customer happy. I, as their customer, made a purchase on a faith that it would work. It worked perfectly and precisely as they advertised. I am beyond happy with 80% Arms and not only will I return, I will share my great experience with others. Thank you 80% Arms for making this build a ridiculously easy piece of cake.

Win a FREE Membership!

Win a FREE Membership!