|

Posted: 3/11/2014 4:52:22 AM EDT

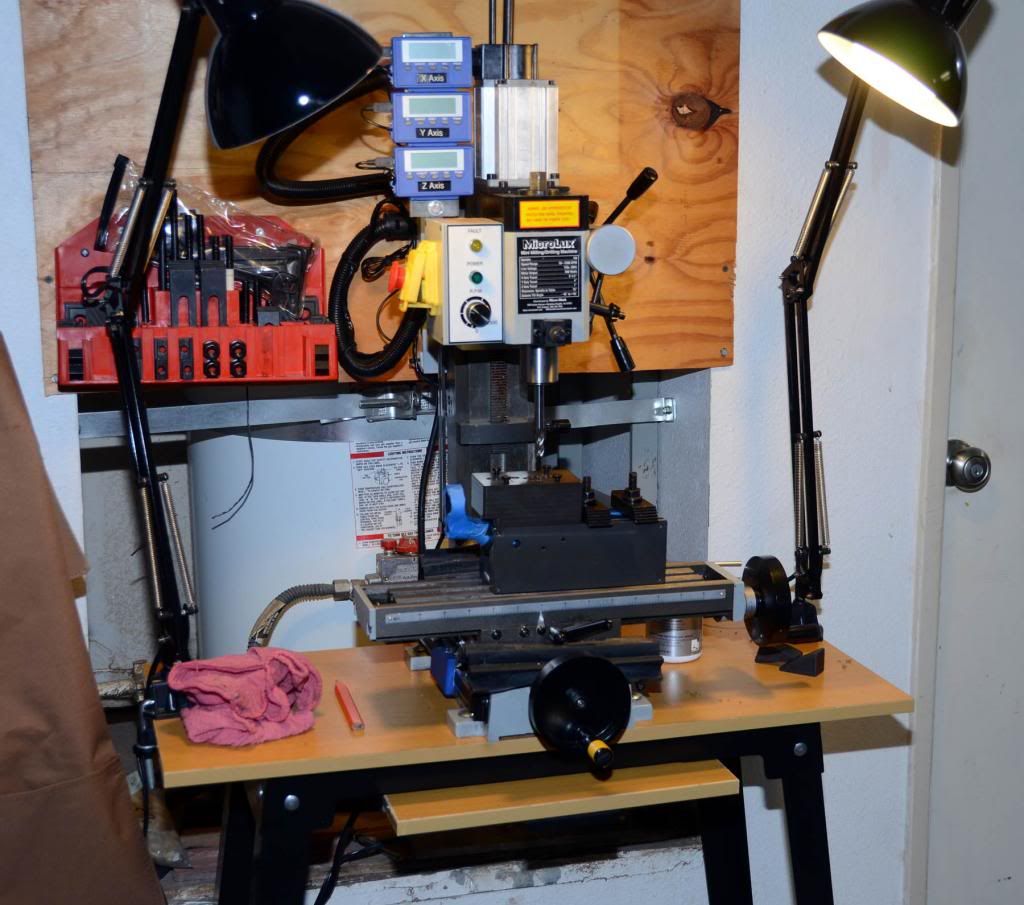

Mill is up and running. So far I've only completed two three 80% lowers, but I've started several small projects. Most of my effort has been setting up the mill. Complete tear down, deburr, clean up and re-assemble, Installing DRO's, Air Spring conversion, spindle lock(in progress), lights(in progress), Tach (in progress). Lots of pics!

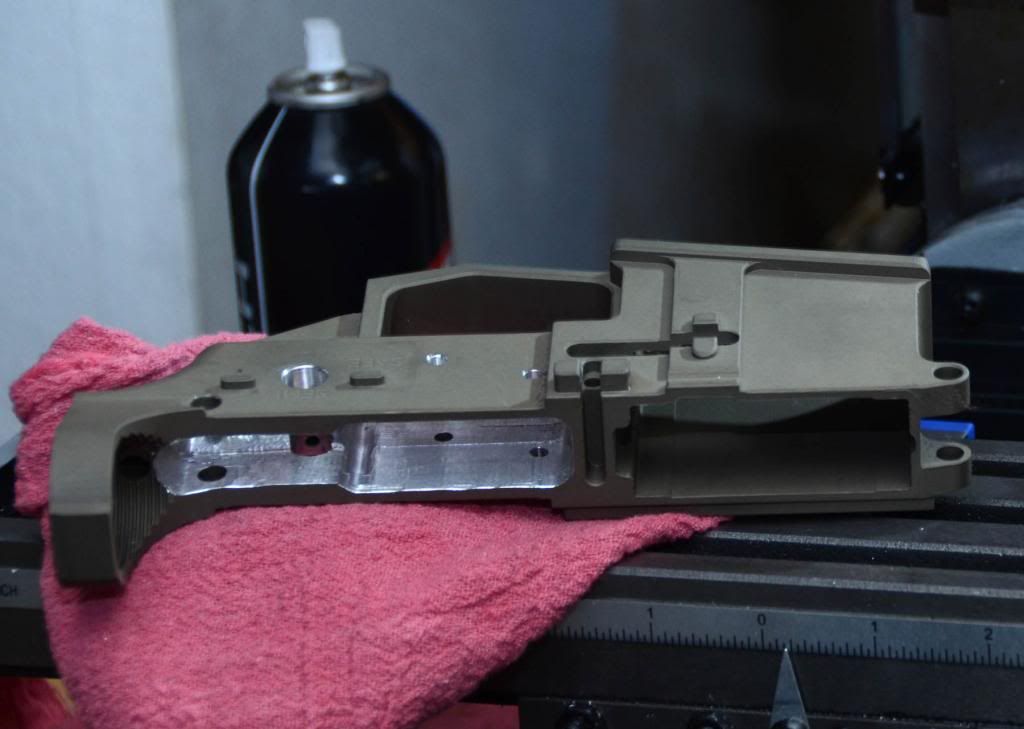

Original Post: Which one do you have, or have you owned? What do you like about them? What don't you like about them? Any gaps between your needs and their abilities? I have my eye on LMS Hi Torque Probably one of the packages with some tooling Like This. Although I haven't done a lot of research on the DRO's, I've heard they can be found pretty cheap. I haven't found them "cheap" though. I understand the tooling will add up fast and continuously, but I'd like to keep the initial buy-in under $1500 I already have a small lathe, about a 24" bed. This will be used primarily for firearms related machining, but could serve for any small projects I dream up. So with that, feel free to flaunt your projects. TIA Updates... ETA: Got the HiTorque from LMS Chips are flying ! Sources for 80% Lowers I've used. Coate's Carbine (so far, probably my favorite for cost to quality ratio. Small company, but VERY fast shipping) TR Enabling (Very nice quality, not a fan of the "look" of the trigger guard, but otherwise VERY nice, I bought them on a good sale $69 each with free shipping) I also bought their Jig as the Ares was backordered, it is a simple designed Jig that worked well, but I like the Ares Jig better. The Ares Jig pictured below is thicker and anodized black. The TR Enabling jig is the much thinner and "raw" jig pictured. Ares Armory (I bought the "RAW" lowers, cosmetic machining flaws, but pretty nice otherwise. Shipping was somewhat slow and the JIG was backordered, took 2 months, but I like this Jig better than the TR Enabling Jig) Note on Jigs: Both of these jigs stick up quite a bit from the top deck of the receiver. This gives the chips a place to accumulate, rather than galling up. But it makes it necessary to use extra long end mills that cost, flex and break more than shorter end mills. Also, it really cuts down on your view of your work. Using hindsight, I would prefer a jig that the side plates sit flush with the top deck of the receiver. Ares Lower and TR Enabling Jig

FCG Pocket complete !

It works, that magazine didn't empty itself!

Second 80%, opted for an anodized finish. Getting better. Much cleaner milling, finished this one in about 3 hours, start to finish. Could have been about half that time, but I was testing options. Coats Carbine lower and Ares Jig

Mill Mods: Spindle Lock. Squaring up stock to build a Spindle Lock

Ready to mount, the plunger looks like a bolt, but it's hardened 1/4" steel rod, I opened up the spindle hole to accept a heavier rod. Milled a flat on the rod to accept a set screw for capturing, threaded the end for a nut to hold the spring and use as a "button" to depress when locing the spindle. It's amazing how nice this little mods helps with every tooling swap. forget those stupid spanner wrenches. Obviously I had to use longer bolts, but I used the existing bolt holes for the cover around the bottom side of the spindle. I thought about recessing a channel for the LED I'll be mounting, but not being recessed would allow for better lighting and I don't think it will be exposed enough to matter. A look at the plunger (looks like a bolt, but it's just the exposed spring) I could have had the spring internal, but the capturing solutions would have weakened the rod too close to the spindle. This was easy enough and works great.

The end that contacts the spindle

|

|

|

|

http://www.mini-lathe.com/Mini_mill/Reviews/Reviews.htm

This guy has pretty much reviewed all the Chinese small mills and lathes. A worthwhile read if you're considering a small mill. Al |

|

|

|

|

|

I have the Harbor Freight Mini-mill. I have completed three 80% lowers on it without a hitch. I paid $400 for it when it was on sale, I had an additional 25% off coupon, bringing it down fro $600. I spent an additional $60 for mill bits and $50 for a 7/16 mill set. So far no problems with it. It has proven to be a valuable addition to my garage workshop since it doubles as a drill press.

http://www.amazon.com/Anytime-Tools-Slot-CLAMP-CLAMPING/dp/B007DMLBZ6/ref=sr_1_2?ie=UTF8&qid=1394554964&sr=8-2&keywords=7%2F16+mill+set http://www.amazon.com/End-Mill-Set-pieces-Flute/dp/B002YPHSJK/ref=sr_1_1?ie=UTF8&qid=1394554964&sr=8-1&keywords=7%2F16+mill+set http://www.harborfreight.com/two-speed-variable-bench-mill-drill-machine-44991.html |

|

|

|

|

|

Quoted:

How much is that puppy...I would love that! View Quote View All Quotes View All Quotes Quoted:

Quoted:

How about a micro Bench-top CNC Mill How much is that puppy...I would love that! ^^^This All of the small cnc's ice looked at are in the $4-5k range. That does not include a pc or software. Decent CAD software is pricey. |

|

|

|

Quoted:

How much is that puppy...I would love that! View Quote View All Quotes View All Quotes Quoted:

Quoted:

How about a micro Bench-top CNC Mill How much is that puppy...I would love that! If you have a Pc already. You get starter package for a Taig between $1500-2400 For my all my machining so far... including the coding for the FCG and pin hole for my 80% I use a great little CAM program called CamBam. Yes you can get into High$$ software packages as needed.. But I just add to it as I need it... just like my AR's Ca_Longshot |

|

|

|

Quoted:

If you have a Pc already. You get starter package for a Taig between $1500-2400 For my all my machining so far... including the coding for the FCG and pin hole for my 80% I use a great little CAM program called CamBam. Yes you can get into High$$ software packages as needed.. But I just add to it as I need it... just like my AR's Ca_Longshot View Quote View All Quotes View All Quotes Quoted:

Quoted:

Quoted:

How about a micro Bench-top CNC Mill How much is that puppy...I would love that! If you have a Pc already. You get starter package for a Taig between $1500-2400 For my all my machining so far... including the coding for the FCG and pin hole for my 80% I use a great little CAM program called CamBam. Yes you can get into High$$ software packages as needed.. But I just add to it as I need it... just like my AR's Ca_Longshot Have a lubrication system on it, I'm just impressed with the enclosure the most, was that built by you, or something you bought from Taig? |

|

|

|

That is a very nice setup for a non shop deal. would look good in my garage on the back of my property.

|

|

|

|

|

|

Quoted:

If you have a Pc already. You get starter package for a Taig between $1500-2400 For my all my machining so far... including the coding for the FCG and pin hole for my 80% I use a great little CAM program called CamBam. Yes you can get into High$$ software packages as needed.. But I just add to it as I need it... just like my AR's Ca_Longshot View Quote Thanks for the reply...I have such a bad time remembering to "subscribe" after I post. |

|

|

|

Quoted: How about a micro Bench-top CNC Mill http://photos.imageevent.com/scl_electronics/misc/taigstuff/websize/enclosure5.jpg http://photos.imageevent.com/scl_electronics/cfguns/ar15/websize/lower1.jpghttp://photos.imageevent.com/scl_electronics/cfguns/ar15/websize/bare31.jpg It doe have a vertical (z axis) limitations.. It also can't Hog large chunks in one pass... But that is what CNC is for.... I just let the computer do all the repetitive work!! Ca_Longshot View Quote awesome setup,this is just beyond ridiculously cool  I've been thinking about the HF 2spd mini mill/drill to finish 3-4 80% lowers and makes some tooling and just general tinkering around |

|

|

|

Quoted:

How about a micro Bench-top CNC Mill View Quote Wish I had the money and space to buy one of these. Are you just finishing 80% lowers with this or are you machining them from solid blocks? Also, would there be any legal issues with these? Since I'm not a gunsmith would I get in trouble for making myself a lower and possibly making one to gift out? Just curious since I have zero knowledge of this stuff. |

|

|

|

I have the Micromark mini mill - to which I installed the LMS solid column conversion kit.

Thus my mill is now almost identical to the LMS mill except their mill has a slightly bigger table. These "second generation" mills have addressed some of the complaints of the earlier versions, and they now have brushless DC motors with electronic speed control, belt drive, the solid column (which improves rigidity) and R8 spindles. When I got mine I was limited by size and weight constraints, otherwise I might have gone with one of the somewhat larger mills from Grizzly, but so far I've been able to do everything I wanted to do with it, and I don't have any complaints. I added an Igaging DRO on each axis...and I now cannot imagine using the mill without these. Adding them made a big difference in "user friendliness". I was able to install the Igaging DROs without drilling any holes in the mill at all. In fact, for the Z axis, I used the preexisting holes on the left side of the column...all I had to do was to turn one of the Igaging supplied brackets around the other way, and the holes lined up perfectly. For the other two axes I made some hardware that just bolted on to the table using existing holes and it's been working good so far. The Igaging DROs are relatively cheap and I think you can get them on Ebay, Amazon and from Grizzly. Quoted:

Which one do you have, or have you owned? What do you like about them? What don't you like about them? Any gaps between your needs and their abilities? I have my eye on LMS Hi Torque Probably one of the packages with some tooling Like This. Although I haven't done a lot of research on the DRO's, I've heard they can be found pretty cheap. I haven't found them "cheap" though. I understand the tooling will add up fast and continuously, but I'd like to keep the initial buy-in under $1500 I already have a small lathe, about a 24" bed. This will be used primarily for firearms related machining, but could serve for any small projects I dream up. So with that, feel free to flaunt your projects. TIA View Quote |

|

|

|

Thanks for all of the info. Anybody care to share some of their projects? I have a small list of things I want. A couple 80%'s, maybe a side charger, some other tools, ect.

|

|

|

|

Quoted:

Wish I had the money and space to buy one of these. Are you just finishing 80% lowers with this or are you machining them from solid blocks? Also, would there be any legal issues with these? Since I'm not a gunsmith would I get in trouble for making myself a lower and possibly making one to gift out? Just curious since I have zero knowledge of this stuff. View Quote View All Quotes View All Quotes Quoted:

Quoted:

How about a micro Bench-top CNC Mill Wish I had the money and space to buy one of these. Are you just finishing 80% lowers with this or are you machining them from solid blocks? Also, would there be any legal issues with these? Since I'm not a gunsmith would I get in trouble for making myself a lower and possibly making one to gift out? Just curious since I have zero knowledge of this stuff. I have been doing 80% for a while now... I have been wanting to get a 3D CAD program to design mill a full lower on my Taig.. The big challenge is to work on the logistics of fully machining it on the TAIG!!! On the Legal side of things.. As It stands today.... In MOST locations, it is still legal to make your AR out of a 80% for PERSONAL Use........ But things are changings..... Work Fast!!! Good Luck, Stuart |

|

|

|

Quoted:

Thanks for all of the info. Anybody care to share some of their projects? I have a small list of things I want. A couple 80%'s, maybe a side charger, some other tools, ect. View Quote Check this post I did in the Rimfire and Pistol Calibers Area. .357 Sig Super I am building and modifying my pistol Cartridge Carbine DI upper. It is a 10mm neck down to 9mm. I have been modifying the mags and mag-block , so the bolt catch will operate correctly....

There are also photos to come on my Custom .20Tact. JP Side-Charging, Osprey piston Upper...... Ca_Longshot |

|

|

|

I have that EXACT mini on order. Should be here tomorrow or next day. I have wanted one for a few years. I did at their 2 axis DRO. I have spend HOURS researching the various models of these and came to the conclusion that LittleMachineShop had the best one. I didn't order the tool package since I have some stuff already and ordered some stuff separately. I did order the airspring upgrade, the swivel vise and a couple small things. I just went back and ordered the spindle lock and will add my own lock out limit switch. I bought a Edsal 18x30 bench and am going tomorrow to grab a piece of 3/4"plywood to set on top to help. The bench is very solid but the top shelf is still not 1/2 inch steel so I want to make it stiffer. I found that Shars is a decent tooling supplier for the home type user. I have some indicators and other tooling like I mentioned and I can source some stuff from where I work.

I don't want a CNC at this level. Not like its a Heller/Mazak/Hass type thing. I can just do it by hand instead of the time it takes to do all the G code programming. IF I made more than a few of things it might be OK. I will put up some pics of my basic set up. Its going to take a few days to get it unpacked and cleaned up. Trammed in and the DRO put on. I got a Shars digital scale for the Z axis. I am set up in the garage and space is a premium or I would have just found a used Bridgeport and a 220 volt converter. PM me if you want to compare notes. |

|

|

|

I have yet to buy a mill but i do have a 14-40 manual lathe. I've not made a lot on it. I bought it for a purpose, then figured out my power in my garage was not adequate to run it. Now, 4 years after i bought it, and 4 months from now, i will have a 30x50 shop with plenty of power to run both a lathe and a mill. So after it's paid off, i will end up getting something to the tune of a Haas mini mill or something of the like. That's all i have to offer to this conversation, sorry. haha. Not a lot of experience with the micros or anything like that besides knowing you can upgrade them pretty heavily and it's only limited by your imagination. I run Mastercam X6 at work but that's about $50k worth of software that i won't be able to afford for a while, so we'll see what i end up with.

|

|

|

|

I had harbor freight model but the motor went out.

And it is a DC motor and I had a hard time finding replacement |

|

|

|

Quoted:

I've got the little Central Machinery one. I've upgraded some of the smaller locking levers and added air for chip cleaning, but am really looking at doing the iGauging DRO thing for it. Haven't used it a ton yet. http://img.photobucket.com/albums/v108/Chrissopher/millstwo_zps8ee5e8ec.jpg This is an older picture of my basement garage/shop. I've added a server rack to the left of the pic to mount the CPU, monitor, and servo drive for the ultra-micro-CNC  . Everything moved down the table a couple of feet so there is a little more bench space. . Everything moved down the table a couple of feet so there is a little more bench space.

That enclosure for the previous CNC setup is pretty slick! I've been hanging plastic sheeting when I have mine cranked up. May go for something more permanent. CHRIS View Quote What kind of mill is the one on the left? |

|

|

|

|

|

|

|

Quoted: Here's something you can make on a mini-mill (I'll see if anyone knows what it is): http://i124.photobucket.com/albums/p31/hpsmith2010/Picture7_zps7e3c8725.jpg http://i124.photobucket.com/albums/p31/hpsmith2010/Picture9_zps7ec0e90e.jpg View Quote CHRIS |

|

|

|

Yep. It's a copy of a Ruger Mk3 receiver, made from a piece of T6061 T6 aluminum pipe - only without the annoying "loaded chamber indicator". (The Mk3 receiver is very similar to the Mk2 receiver...it just has some minor changes, e.g., the ejection port is machined a little differently and the chamfer on each side of the ejector is now 60 degrees instead of 45 and 60).

Quoted:

Looks kind of like a Ruger receiver. CHRIS View Quote View All Quotes View All Quotes Quoted:

Quoted:

Here's something you can make on a mini-mill (I'll see if anyone knows what it is): http://i124.photobucket.com/albums/p31/hpsmith2010/Picture7_zps7e3c8725.jpg http://i124.photobucket.com/albums/p31/hpsmith2010/Picture9_zps7ec0e90e.jpg CHRIS |

|

|

|

Quoted:

Here's something you can make on a mini-mill (I'll see if anyone knows what it is): http://i124.photobucket.com/albums/p31/hpsmith2010/Picture7_zps7e3c8725.jpg http://i124.photobucket.com/albums/p31/hpsmith2010/Picture9_zps7ec0e90e.jpg View Quote View All Quotes View All Quotes Quoted:

Here's something you can make on a mini-mill (I'll see if anyone knows what it is): http://i124.photobucket.com/albums/p31/hpsmith2010/Picture7_zps7e3c8725.jpg http://i124.photobucket.com/albums/p31/hpsmith2010/Picture9_zps7ec0e90e.jpg Quoted:

Thanks for all of the info. Anybody care to share some of their projects? I have a small list of things I want. A couple 80%'s, maybe a side charger, some other tools, ect. I like it!! Suppose I'm going to need an aluminium alloy source... Be nice if they'd trade for empty beer cans  . .

|

|

|

|

One of these days I'll have to upload a set of plans as to how to make these.

|

|

|

|

Hello,

I have a had a Harbor Freight mini mill fro home use for many years and I can tell you that you are going to have lots of time and patience as even in aluminum you just cannot take large cuts because the column just is not stiff enough and you will stay busy adjusting the gibbs on the table to keep it all tight. I have never had any failures with it that were not caused by me making it do more than what it really intended to do. The www.littlemachineshop.com machines are also very good. I would recommend that whatever one you choose get the R8 spindle version as you can use the tool holders and collets in Bridgeport style knee mills when you move up to one. |

|

|

|

yep good info get R8 spindle. i have a mini mill (HF one ) tooling will eat you up way faster then the mill its self. i cant really see CNC on a tool this small and not made for it. im a knife maker so i dont really know about the gunsmithing side of things. is working AL and taking smallis cuts the mini is fine. after i got my bridgeport the mini mill became a dril press since the BP jsut works so much nicer doing mill cuts

|

|

|

|

Quoted:

Which one do you have, or have you owned? What do you like about them? What don't you like about them? Any gaps between your needs and their abilities? I have my eye on LMS Hi Torque Probably one of the packages with some tooling Like This. Although I haven't done a lot of research on the DRO's, I've heard they can be found pretty cheap. I haven't found them "cheap" though. I understand the tooling will add up fast and continuously, but I'd like to keep the initial buy-in under $1500 I already have a small lathe, about a 24" bed. This will be used primarily for firearms related machining, but could serve for any small projects I dream up. So with that, feel free to flaunt your projects. TIA View Quote Funny, I ordered this exact setup today.... Looking forward to converting to CNC. Oops.. No I got the non-tilting package (4288) |

|

|

|

In reference to the lube system....how much did that run or did you piece it together?

A point to the source of that setup would be great.... Thanx Dale Quoted:

Yes I have a cutting lube system on it.. Accu-Lube Nearly Dry lubricating system http://photos.imageevent.com/scl_electronics/misc/taigstuff/websize/20130121_174150.jpg No choking fog.....parts and chip come out are nearly dry.. The enclosure I designed and built myself for 80/20 T-slot Extrusions, the Engineer's Tinker-Toys!! I got all the raw material from the Ebay store. Ca_Longshot View Quote View All Quotes View All Quotes Quoted:

Quoted:

Have a lubrication system on it, I'm just impressed with the enclosure the most, was that built by you, or something you bought from Taig? Yes I have a cutting lube system on it.. Accu-Lube Nearly Dry lubricating system http://photos.imageevent.com/scl_electronics/misc/taigstuff/websize/20130121_174150.jpg No choking fog.....parts and chip come out are nearly dry.. The enclosure I designed and built myself for 80/20 T-slot Extrusions, the Engineer's Tinker-Toys!! I got all the raw material from the Ebay store. Ca_Longshot |

|

|

|

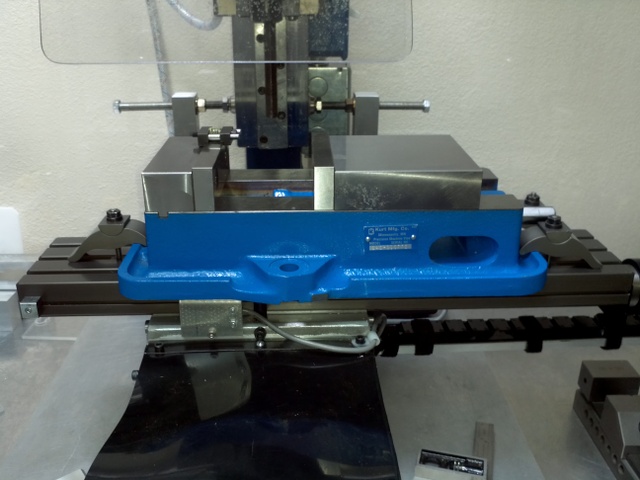

Quoted: How about a micro Bench-top CNC Mill http://photos.imageevent.com/scl_electronics/misc/taigstuff/websize/enclosure5.jpg http://photos.imageevent.com/scl_electronics/cfguns/ar15/websize/lower1.jpghttp://photos.imageevent.com/scl_electronics/cfguns/ar15/websize/bare31.jpg It doe have a vertical (z axis) limitations.. It also can't Hog large chunks in one pass... But that is what CNC is for.... I just let the computer do all the repetitive work!! Ca_Longshot View Quote Seeing a Kurt D60 (or clone thereof) clamped to a mill table that's barely bigger than the vise is, is just WEIRD. I used to have an Enco bench mill which I used to make my first 0 percent receiver. Clearly it was adequate to the job. It was a nice machine which I would recommend if you don't plan to do any heavy cutting in steel. It just didn't have the rigidity for that but for aluminum it's fine. Today I use a full sized Bridgeport clone which is very well tricked out, with 3 axis vision readout (4 axis capable), 30 taper quick change tooling, 18" Brown & Sharpe rotary table, Brown & Sharpe dividing head, two Kurt and one clone D60 vises, and a cart full of tooling. It's way overkill for the job of making lowers but I don't really mind. |

|

|

|

I believe the saying is "you can do a small job on a big machine, but you can't do a big job on a small machine"

I will probably end up with an old Bridgeport in the end, but for now, I don't have the space nor the need. That could change, for now I'm just getting my feet wet. Should be here a week from today. |

|

|

|

Quoted:

I believe the saying is "you can do a small job on a big machine, but you can't do a big job on a small machine" I will probably end up with an old Bridgeport in the end, but for now, I don't have the space nor the need. That could change, for now I'm just getting my feet wet. Should be here a week from today. View Quote Awesome.. Mine will be here Friday.. Will you convert to CNC immediately or learn to use manually first? |

|

|

|

My advice is to learn manual machining before CNC.

Knowing manual machining gives you the understanding necessary to approach CNC machining from a practical and safe perspective. If nothing else, it gives you a reasonable perspective on speeds, feeds, tooling, and cooling. How to cut what, and with what, and how much you can cut at once. Knowing how to make something manually is a very good first step toward figuring out how to make the computer do the same thing. |

|

|

|

Quoted:

In reference to the lube system....how much did that run or did you piece it together? A point to the source of that setup would be great.... Thanx Dale View Quote View All Quotes View All Quotes Quoted:

In reference to the lube system....how much did that run or did you piece it together? A point to the source of that setup would be great.... Thanx Dale The unit I am using is the Accu-Lube Junior MQL system. you can read all bout it here : Accu-Lube I picked mine up on Ebay... about 1/2 of retail.... But you can get through MSC..$$$ Then I added the Filter/Reg unit. Also the solenoid valve to control it from Mach3 Quoted:

Seeing a Kurt D60 (or clone thereof) clamped to a mill table that's barely bigger than the vise is, is just WEIRD. I used to have an Enco bench mill which I used to make my first 0 percent receiver. Clearly it was adequate to the job. It was a nice machine which I would recommend if you don't plan to do any heavy cutting in steel. It just didn't have the rigidity for that but for aluminum it's fine. Today I use a full sized Bridgeport clone which is very well tricked out, with 3 axis vision readout (4 axis capable), 30 taper quick change tooling, 18" Brown & Sharpe rotary table, Brown & Sharpe dividing head, two Kurt and one clone D60 vises, and a cart full of tooling. It's way overkill for the job of making lowers but I don't really mind. Well it would really Weird if it was a D60 on my Taig... But it is a D40 (4 inch) It works just fine for me.....

I wish I had the space for a full sized Haas....... But have to make do with what you have Room for! Like I said... It may not Hog out a FCG pocket in 15 min.... but it will get done perfectly in 30 min... But I let the computer do all the work.... Ca_Longshot |

|

|

|

OK. You mill guys have as much specialized terminology as any other specialized group, and I can't follow 80% of it. But, I gotta say, I very much respect the skill set and time spent on your craft that you guys bring to the game. Please keep posting so that we, on the other non machinist side, can get a glimpse into your art.

Best to you! |

|

|

|

That reminds me, I want to get a Kurt D40 vise.

I have a D60, a D675, and a clone of a D60. Three vises for one mill? I'd trade straight across, any one of these for a D40. A D40 is the right size for a lot of jobs. The larger D60 is often overkill. |

|

|

|

you guys looking for good price dro i found these guys awhile ago and they have good reviews

|

|

|

|

Quoted:

Which one do you have, or have you owned? What do you like about them? What don't you like about them? Any gaps between your needs and their abilities? I have my eye on LMS Hi Torque Probably one of the packages with some tooling Like This. Although I haven't done a lot of research on the DRO's, I've heard they can be found pretty cheap. I haven't found them "cheap" though. I understand the tooling will add up fast and continuously, but I'd like to keep the initial buy-in under $1500 I already have a small lathe, about a 24" bed. This will be used primarily for firearms related machining, but could serve for any small projects I dream up. So with that, feel free to flaunt your projects. TIA View Quote I have this one. Picked it up for 20% off on Black Friday.

I like it but don't know any better. What I like:

I put the DROs on myself and it wasn't that hard at all. |

|

|

|

I got the mill.

Complete: Tore down, de-burred, cleaned and lubed and reassembled. Table built, mill mounted, air spring conversion installed and Z axis DRO installed. Incomplete: X axis DRO, Y axis DRO, Tach, Tram, LED light ring, column support. Someday (Reality version) Power feeds Wish I had the DRO's setup so I could use the mill to make DRO mounts.

|

|

|

|

|

|

Quoted: I got the mill. Complete: Tore down, de-burred, cleaned and lubed and reassembled. Table built, mill mounted, air spring conversion installed and Z axis DRO installed. Incomplete: X axis DRO, Y axis DRO, Tach, Tram, LED light ring, column support. Someday (Reality version) Power feeds Wish I had the DRO's setup so I could use the mill to make DRO mounts.  View Quote I just received my 3960 and have decided to just do the cnc conversion vs DRO... AM I mistaken here? Do I need both?

|

|

|

|

Quoted:

Do you plan On converting it to CNC? I just received my 3960 and have decided to just do the cnc conversion vs DRO... AM I mistaken here? Do I need both? View Quote View All Quotes View All Quotes Quoted:

Quoted:

I got the mill. Complete: Tore down, de-burred, cleaned and lubed and reassembled. Table built, mill mounted, air spring conversion installed and Z axis DRO installed. Incomplete: X axis DRO, Y axis DRO, Tach, Tram, LED light ring, column support. Someday (Reality version) Power feeds Wish I had the DRO's setup so I could use the mill to make DRO mounts.  I might convert to CNC one day, but want to learn the machine and manual milling first. |

|

|

|

I have a Rong Fu (check spelling) Mill drill.No way does it compare to a Bridgeport, the machine I learned on from a older friend who owned a machine shop. My brothers friend was partners in a local machine shop. When I was 16( I will be 60 in May I wanted to build a cross bow using a leaf spring from a auto. and needed a metal band saw to cut out the profile.The shop was about 1300 sq.ft and some what messy, but Herman could fix it if it was broken, He would fix our motor cycles for nothing. It was an adventure to go his shop his shop, He was a WWII vet (ARMY south pacific ) several others who were regulars were also WWII vets Marine, Navy, also South Pacific (Lati Gulf). Sorry to say they are all gone now. Sorry for getting off topic. The Mill drill can do decent milling but it takes extra effort. The biggest draw back is it does not have a knee work surface. The second is the read out of the quill, its accurate but difficult to use. I have made a 0% AR15 receiver on it, and a breach loading black powder cannon. I recently got a DRO set for it.

I have installed the Quill readout and am in the process of installing the other two.Yes I would like to have a full size mill and could now where I currently live, ground level basement entry. Even though I have a 1600 SQ.FT. shop a full size mill would take up a lot of room. (I have two lathes, a cutter grinder 2x72 belt grinder 12" disk sander, two band saws, air compressor, 4x8 work bench and other work benches. The small mill drill will fill a slot in a pinch. |

|

|

|

Got the DRO's installed, Trammed it all up. Letting the chips fly. Didn't get much time on it yet, but so far, I'm happy with it.

|

|

|

|

I purchased one of the Central machinery mini mills. Still playing with it to see what it can do. I am actually surprised at the depth of cut I can do on 7075. I am not doing a lower manually in a half hour, but it gets done. Tooling will be an expense. Right now I am using the R8 chuck that came with it, but I need to get some collets for greater capacity on the Y axis. DRO's are definitely needed, and the lash takes some getting used to. I can see this thing set up as a little cnc, and doing quite a bit of work, but not fast. Pocket milling would still be about a half hour with a CNC set up on it. I need some more projects to play with it and learn milling. I like the side charger idea. Can that be done leaving the charge handle, and the forward assist? I assume the Brenton bump would need to be removed.

|

|

|

|

I don't want to make a new thread for this since this thread already covers my question.

I want a CNC machine JUST dedicated to a custom rollmark. Which one should I be looking at? I want it to look %110 professional and flawless. Before anyone suggests sending a lower to an engraver, I already looked at that option. No one will touch my rollmark since I don't own the rights to the image. I also realize that I will need a computer and the ability to write the code. Let's pretend I have all that covered and just need a machine. Any help would be awesome. |

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.