Thanks! I seem to remember a place that sold actual Pelican replacement foam, which was fairly cheap. If someone has a link to that or anything cheaper, let me know. Once again, great writeup! |

||

|

|

|

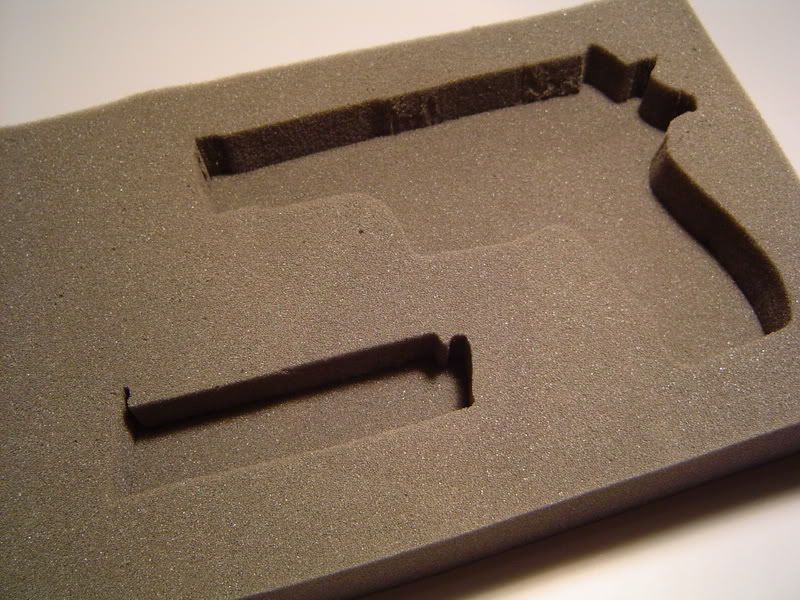

Just got my hot wire cutter in from Hot Wire Cutter and it works GREAT. Did some test cuts to sharpen my skillz before attempting on my Pelican case.

Not too bad for my 1st try!  Thanks Mark for the great write up on this, your directions were a big help. |

|

|

Was it this PLACE? |

|||

|

|

|

Just got my Pelican 1720 in tan. Now I'm going to order the foam cutter and start planning. It is difficult when I don't have all the parts and pieces for my future plans. Just have to try and leave enough room for future expansion and editions.

|

|

|

|

can i fit into a pelican

1) mossberg 500 1) ar15 16' car with m203 launcher 1) glock 26 a few clips and ammo and thats about it, anyone can ellaborate? |

|

|

|

I have a number of cases I've needed to do for a while. In the past, I've done them with a collection of sharp knives, but the hot wire approach looks a whole lot easier. I haven't had time to cut the foam, much less make my own hot wire cutter, so the commercial ones are appealing. I did a little digging on-line, and in addition to the Hot Wire Foam Factory cutter mentioned earlier, there is a fancier one from Proxxon:

Proxxon Hot Wire Cutter  It has adjustable power, and comes with a miter gauge & fence. The Foam Factory version with a fixed power supply is ~$56. If you want variable power, the fancier supply kicks the cost up to ~$112. The Proxxon sells for around $102. The only downside I see to the Proxxon is that because the base is higher, long pieces of foam for rifle case will droop a lot more. I figure I can always prop it up or make a support platform if that becomes an issue. I have cases with both the usual grey polyester foam, and some with a darker polyethylene foam. The polyethylene is a bit stiffer, but it is immune to gun oils and won't deteriorate over time. Two of the cases I need to do are ones I did a couple decades ago and the polyester foam has turned to mush in places. Has anyone used the hot wire approach on polyethylene foam? I assume it will work OK. I was also wondering what folks would recommend for template material. It would be nice to have something stiff enough to glide the wire along, but it would have to be heat proof and easy to secure to the foam. |

|

|

|

Anyone have issues with the surface of the cut being "tacky" after cutting/easing the edges with a micro torch? My foam has a tackiness that is annoying. I rub off into my ar & accessories.

|

|

|

My hot wire cutter is ordered. Now the wait. I HATE the wait. |

|

|

|

|

What model Pelican? I use a 1750 for a MK12 MOD0 (Magpul PRS Stock) and MOD1 (LMT SOPMOD Stock), complete with scopes, bipods and four, 20 round mags. Fits perfectly (dependent on how you set them up). As said earlier in this thread, planning the initial stages and then executing the plan with patience makes it well worth it in the end

|

|

|

|

|

If anyone wants to do this on the cheap, use a soldering iron mounted on the bottom of the board, drill the hole, wrap a fine wire around the soldering iron tip and route it in the same manner. Use this 'type': Soldering Iron ...andy

|

|

|

|

Damn you... and your Iron Dot!

Don't mind him, he's just jealous. |

|

|

|

|

|

That's my next project is a 1750 to hold 2 guns with optics. I wanted ot leave the optics mounted, but I don't see any possibility of that working.

Yours looks good. |

|

|

|

I would also like to warn people about surface rust.

The foam is a magnet for moisture. A almost 100% cure is after you cut your project, get a can of spray silicon. spray both sides of the foam heavy, it will soak deep in the foam. Unlike gun oil, it will almost be undetectable to the touch once it soaks in the cells. It will provide the protection you need. Spray on in mulit coats. It will be easy to tell when you have enough. you can over spray so be carefull. Iforgot to mention: dont use this method if you store optics that dont have lens caps. silicon will get on lens. |

|

|

|

How did I miss this thread? Thanks mfingar!

BTW, I just got a couple of your posters - very nice work indeed! |

|

|

|

Is there any rule of thumb as to how much space should be between items in your case? I might be trying to squeeze too much stuff into my case. I've got everything layed out but several items like a light, bipod and some mags pnly have a 1/2 inch of space/foam between them. Is that doable? |

|

|

|

This is one of the most helpful threads I have found.

Now all my pelican cases will look professional! |

|

|

my first try looks um...... less than professional. I'm hoping next time comes out better now with the use of this thread. |

|

|

|

|

nice job. I have boatloads of 2" foam and a special foam cutter. A work perk!!!

|

|

|

|

OK, a group of the Hosuton Crew are going to go in together and purchase a foam cutter.

which ones work best? SC |

|

|

|

SC,

I'm in Houston as well and I've been looking around town and found the Wonder Cutter like what is used works the best. It's only 6.99 at Hobby Lobby. Now from MFingar's notes it seems easy to modify it like his or you can hold it by hand and with a huge piece of foam that may be difficult. Ryan Infinite1 |

|

|

|

Great thread! Anyone got a link to the posters discussed above?

|

|

|

Mark seems to do everything well. Heres the poster you may be referring to. I dont know if hes still selling them or not. I know he had lots of trouble with the post office tearing them up during shipping. I have one and they are awesome.

|

|

|

|

Thanks. I'm still selling them, and I've solved the USPS problems with some serious packaging changes. I haven't had a problem in two months now Mark |

||

|

|

|

I bough this from a seller on ebay, is that eher you sell Mark?

|

|

|

Yep... "My favorite fish"...remember? Back on track, I'll be doing another complex foam-cutting project. I might consilidate many of the thoughts and great ideas from this thread and see if we can get it tacked. |

|

|

|

I Just saw the "very durable" mailing tube mine came in, and lo & behold, the return address is from Mark Fingar, what a coinkeydink! |

||

|

|

LOL ...like an indian, no part goes to waste. Tomorrow night, I'll be starting another foam project. I'll probably start a new thread. |

|||

|

|

|

the hardest part is trying to align the rod so the wire is straight, go also cut slow so the wire has enough time to melt the foam...also remember the shorter the wire, the hotter it is=better, smoother cuts imo

|

|

|

|

So i finished cutting the foam for my pelican 1750 and went to round the edges like Mfingar mentioned with a small butan torch and the result was not so good.

Has anyone else tried this? can anyone explain this process in more detail? |

|

|

|

Cool thread, nice work.

Combined with your photoshop skills, you're a man of useful talents. |

|

|

|

OK, got impatient (as usual) and cut with an electric knife. It's functional, but far from pretty. In fact if Mark saw it he'd probably punch me in the mouth

If patience is a virtue, I'm going to burn in the hottest part of hell. Expect no pics If patience is a virtue, I'm going to burn in the hottest part of hell. Expect no pics |

|

|

|

|

|

So once you make the cuts on one template obviously you have to turn off the foam cutter to get it ready for the next one. Now how long does it take the wire to cool down?

|

|

|

Actually, the one that I used cools instantly once power is cut off from it. YMMV. |

|

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.