|

[#1]

Quoted:

Is there any documentation out there on what M993 and M995 can and can't penetrate. I would have thought M993 would go through level IV? View Quote View All Quotes View All Quotes Quoted:

Quoted:

If youre on a tight budget and youre just internet commando that will probably only wear his armor once a year to the range, if that then ar500 plates are fine. For everyone else ceramic is a no brainer, its lighter, stronger, doesnt have a weakness vs m193 or m855a1. You can get lvl 4 stand alone ceramic plates that are several lbs lighter than steel and they will stop AP rounds such as, M61, M2, 7.62x39, KM993, M995, etc... EDIT: Also over the last few years it seems the price of steel armor, with all of their new features has gone up while ceramic plates have come down in price. Once that price gap closes a little more steel armor will be obsolete. I recall reading that it an ESAPI could stop a M993/M995 round but not sure where, could have just been on some random forum in which case it means nothing. I was able to find the following: This company claims their lvl IV plates are capable of stopping M993/M995 http://www.att-tactical.com/att_ballistics_rifle-plates.html An article written by the ballistic expert Dr. Gary K Roberts, basically warns that not all ESAPI/NIJ lvl IV plates are rated to stop all AP rounds, they are only tested against the common M2 AP round. http://www.lightfighter.net/fileSendAction/fcType/0/fcOid/35788414597316648/filePointer/35788414597316669/fodoid/35788414597316662/Good%20Rifle%20Plate%20Options%20for%20LEOS.pdf The company that produces the ammo says M993 can penetrate 18mm of hardened steel and 12mm with M995. Bother are capable of defeating "heavy" body armor, whatever that's supposed to mean. http://deanlight.se/wp-content/uploads/2011/11/Nammo_1.pdf Random info about m993/m995 http://www.dtic.mil/ndia/2015smallarms/17379_Erninge.pdf Seems the ammo was either never officially tested versus ceramic body armor or if it was the results were not made public. Only real official test data is against steel, so we know without a doubt it would defeat AR500 armor but the 12-18 mm penetration data doesn't translate easily to ceramic armor. Only way to know for sure would be to get a hold of a couple of rounds and test against a ceramic plate, but as a collector of AP ammo ive spent a number late evenings digging through the internet with no success. I would imagine you probably would need to find someone who is active duty and has access to such ammo to "accidently" drop a round or two in their pocket while at the range. |

|

|

|

[#2]

you can find the M995 spec here: http://everyspec.com/MIL-PRF/MIL-PRF-030000-79999/MIL-PRF-71208A_30485/

The penetration requirements are on page 6. There has never been a ceramic body armor penetration requirement for US AP rifle ammo 3.5.9 Penetration. When fired at 0 degrees obliquity, the bullet of the cartridge shall be capable of the following penetration requirements: Material and thickness Range Required penetration 3.5mm NATO plate 656 yds (600 m) 50% 12mm steel armor plate 109 yds (100 m) 100% 1/2 inch aluminum plate 492 yds (450 m) 50% 1/8 inch steel RHA plate 601 yds (550 m) 50% Hollow concrete block (through both sides) 54.7 yds (50 m) 50% 1/4 inch steel RHA plate 437 yds (400 m) 50% 3/8 inch steel RHA plate 262 yds (240 m) 50% 1/2 inch steel RHA plate 164 yds (150 m) 50% |

|

|

|

[#3]

and the penetration specs for M993:

3.5.7 Penetration. For each test below, the projectile of the cartridge shall penetrate 7mm thick High Hardness Armor (HHA) plate, in accordance with MIL-DTL-46100, creating a hole through which daylight can be seen. 3.5.7.1 Penetration at 546.8 yards. The bullet of the cartridge shall be capable of penetrating the HHA plate at 0 degrees obliquity at a minimum range of 546.8 yards (500 meters). 3.5.7.2 Penetration at 716.3 yards. The bullet of the cartridge shall be capable of penetrating the HHA plate at 0 degrees obliquity at a minimum range of 716.3 yards (655 meters) with a success rate of not less than 50%. |

|

|

|

[#4]

Huh, thought pretty much nothing could touch my ceramics. Guess everyone has to worry about something....

But for the same price and less weight I like being in the position to worry about the least amount of stuff flying around out there..... |

|

|

|

[#5]

Quoted:

I recall reading that it an ESAPI could stop a M993/M995 round but not sure where, could have just been on some random forum in which case it means nothing. I was able to find the following: This company claims their lvl IV plates are capable of stopping M993/M995 http://www.att-tactical.com/att_ballistics_rifle-plates.html An article written by the ballistic expert Dr. Gary K Roberts, basically warns that not all ESAPI/NIJ lvl IV plates are rated to stop all AP rounds, they are only tested against the common M2 AP round. http://www.lightfighter.net/fileSendAction/fcType/0/fcOid/35788414597316648/filePointer/35788414597316669/fodoid/35788414597316662/Good%20Rifle%20Plate%20Options%20for%20LEOS.pdf The company that produces the ammo says M993 can penetrate 18mm of hardened steel and 12mm with M995. Bother are capable of defeating "heavy" body armor, whatever that's supposed to mean. http://deanlight.se/wp-content/uploads/2011/11/Nammo_1.pdf Random info about m993/m995 http://www.dtic.mil/ndia/2015smallarms/17379_Erninge.pdf Seems the ammo was either never officially tested versus ceramic body armor or if it was the results were not made public. Only real official test data is against steel, so we know without a doubt it would defeat AR500 armor but the 12-18 mm penetration data doesn't translate easily to ceramic armor. Only way to know for sure would be to get a hold of a couple of rounds and test against a ceramic plate, but as a collector of AP ammo ive spent a number late evenings digging through the internet with no success. I would imagine you probably would need to find someone who is active duty and has access to such ammo to "accidently" drop a round or two in their pocket while at the range. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Quoted:

If youre on a tight budget and youre just internet commando that will probably only wear his armor once a year to the range, if that then ar500 plates are fine. For everyone else ceramic is a no brainer, its lighter, stronger, doesnt have a weakness vs m193 or m855a1. You can get lvl 4 stand alone ceramic plates that are several lbs lighter than steel and they will stop AP rounds such as, M61, M2, 7.62x39, KM993, M995, etc... EDIT: Also over the last few years it seems the price of steel armor, with all of their new features has gone up while ceramic plates have come down in price. Once that price gap closes a little more steel armor will be obsolete. I recall reading that it an ESAPI could stop a M993/M995 round but not sure where, could have just been on some random forum in which case it means nothing. I was able to find the following: This company claims their lvl IV plates are capable of stopping M993/M995 http://www.att-tactical.com/att_ballistics_rifle-plates.html An article written by the ballistic expert Dr. Gary K Roberts, basically warns that not all ESAPI/NIJ lvl IV plates are rated to stop all AP rounds, they are only tested against the common M2 AP round. http://www.lightfighter.net/fileSendAction/fcType/0/fcOid/35788414597316648/filePointer/35788414597316669/fodoid/35788414597316662/Good%20Rifle%20Plate%20Options%20for%20LEOS.pdf The company that produces the ammo says M993 can penetrate 18mm of hardened steel and 12mm with M995. Bother are capable of defeating "heavy" body armor, whatever that's supposed to mean. http://deanlight.se/wp-content/uploads/2011/11/Nammo_1.pdf Random info about m993/m995 http://www.dtic.mil/ndia/2015smallarms/17379_Erninge.pdf Seems the ammo was either never officially tested versus ceramic body armor or if it was the results were not made public. Only real official test data is against steel, so we know without a doubt it would defeat AR500 armor but the 12-18 mm penetration data doesn't translate easily to ceramic armor. Only way to know for sure would be to get a hold of a couple of rounds and test against a ceramic plate, but as a collector of AP ammo ive spent a number late evenings digging through the internet with no success. I would imagine you probably would need to find someone who is active duty and has access to such ammo to "accidently" drop a round or two in their pocket while at the range. Guess that's my next project then :D I just don't want to waste what I spent time and $$ finding if it won't do anything. I tested a 1/4 and 3/8" MIL-46100 plates back to back at 45' and it defeated m2AP @ 3200 fps. If m993 can penetrate 18mm of that same steel at 100m, I don't see how level IV would stop it. Then again as mentioned it's hard to equate steel penetration to ceramic. |

|

|

|

[#6]

I had some a few years ago as a budget set up. I upgraded to highcom lv 4 plates for $100 per plate.

Since then I have seen testing on the level 3A AR500 which is what most of then are rated. Some 5.56 will cut through it like butter. Common 5.56. So for me I would rather pay $200 for a set of level 4 ceramics than $140 for a set of ar500 that might not stop a common round. And, they are heavy as shit. |

|

|

|

[#7]

I tested my ar500 plates and from around 25 yards 193 went through like butter from a 16" barreled ar15.

If you shop around you can find ceramics for a little more. For me, I don't want to take a chance for $50- $100 difference. |

|

|

|

[#8]

FYI, level 3A isn't rated to stop any rifle rounds. NIJ level III > IIIA

Of course their 'response' to a bunch of rifle rounds that can go through steel III plates is their own designation of III+ plates, not an NIJ rating. But they do seem to fix this issue... By NIJ standards their old level III plates still meet the requirements (of level 3), but lag behind compared to more popular level IV ceramics that are increasingly more available and comparably priced... |

|

|

|

[#9]

Quoted:

FYI, level 3A isn't rated to stop any rifle rounds. NIJ level III > IIIA Of course their 'response' to a bunch of rifle rounds that can go through steel III plates is their own designation of III+ plates, not an NIJ rating. But they do seem to fix this issue... By NIJ standards their old level III plates still meet the requirements (of level 3), but lag behind compared to more popular level IV ceramics that are increasingly more available and comparably priced... View Quote I guess that's why I don't understand people getting the LV III rated AR500 instead of shopping around and getting the LV IV rated ceramics for just a little more. I also don't shit on the AR500 LV III armor. I just hate it when people are buying it and comparing it to LV IV ceramics and then get defensive when people point out the limitations of it. If you buy it understanding it may not stop certain rifle rounds, its heavy, without spall coating its dangerous, then more power to you. Don't buy it as a cheap alternative to LV IV ceramics because they are not the same thing. |

|

|

|

[#10]

Quoted:

Guess that's my next project then :D I just don't want to waste what I spent time and $ finding if it won't do anything. I tested a 1/4 and 3/8" MIL-46100 plates back to back at 45' and it defeated m2AP @ 3200 fps. If m993 can penetrate 18mm of that same steel at 100m, I don't see how level IV would stop it. Then again as mentioned it's hard to equate steel penetration to ceramic. View Quote They don't equate at all. The stopping methods being compared are shear (steel) vs ablative (ceramic) energy mitigation. Very different, from a physics standpoint. |

|

|

|

[#11]

Quoted:

They don't equate at all. The stopping methods being compared are shear (steel) vs ablative (ceramic) energy mitigation. Very different, from a physics standpoint. View Quote Out of curiosity what do you think? Will it defeat lvl 4 ceramics? I want to go back to only worrying about .50 and possibly .338 lol |

|

|

|

[#12]

Quoted:

Out of curiosity what do you think? Will it defeat lvl 4 ceramics? I want to go back to only worrying about .50 and possibly .338 lol View Quote I am sad to say that I never tested M993 against ceramics but I can make a semi-educated guess. Comparing it to M2AP, which is a hardened steel core at ~2700 fps, M993 is a tungsten core at ~3000 fps. Speaking generally and assuming a fairly "standard" composition level IV plate, I would put the odds at around 60-70% for a penetration. However, that's based entirely on a guess and in the real world, a test could reveal very different results. |

|

|

|

[#13]

Quoted:

I am sad to say that I never tested M993 against ceramics but I can make a semi-educated guess. Comparing it to M2AP, which is a hardened steel core at ~2700 fps, M993 is a tungsten core at ~3000 fps. Speaking generally and assuming a fairly "standard" composition level IV plate, I would put the odds at around 60-70% for a penetration. However, that's based entirely on a guess and in the real world, a test could reveal very different results. View Quote Hmmm. Interesting. Thanks! |

|

|

|

[#14]

Quoted:

They don't equate at all. The stopping methods being compared are shear (steel) vs ablative (ceramic) energy mitigation. Very different, from a physics standpoint. View Quote |

|

|

|

[#15]

Quoted:

I am sad to say that I never tested M993 against ceramics but I can make a semi-educated guess. Comparing it to M2AP, which is a hardened steel core at ~2700 fps, M993 is a tungsten core at ~3000 fps. Speaking generally and assuming a fairly "standard" composition level IV plate, I would put the odds at around 60-70% for a penetration. However, that's based entirely on a guess and in the real world, a test could reveal very different results. View Quote Don't tell me I gotta teach y'all math again. First of all, the regular test velocity of the APM2 is 2880 fps. M993 tests at 2980 fps. But, with that said, the APM2 weighs 10.8g, whereas the M993 weighs 8.3g. Do the math. The APM2 actually has more force behind it. Now you're thinking: Tungsten carbide is stronger than tool steel, so it'll penetrate better. That's true. But only sometimes -- not always. If you've got a boron carbide plate, be very afraid of tungsten-cored rounds. But those generally aren't available to civilians anyway -- and, when they are, they're prohibitively expensive. Silicon carbide and alumina plates tend to perform against WC rounds just as well as they perform against steel. In short, I'd reckon that most Level IV plates should stop M993, unless they're made of boron carbide. If you're rocking a steel plate, you're screwed in any case. Yet, with that said, I don't see what people have got against AR500armor. They're pretty straightforward about what they offer, and it's actually really not bad. They're the furthest thing from deceptive; they're actually really honest... in other words, they're no RMA! (Sorry, couldn't help myself. Seriously, though...) |

|

|

|

[#16]

Quoted:

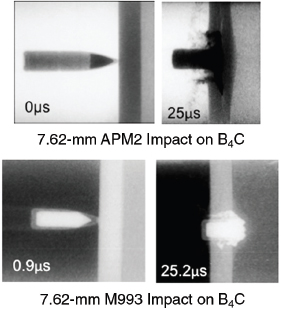

Don't tell me I gotta teach y'all math again. First of all, the regular test velocity of the APM2 is 2880 fps. M993 tests at 2980 fps. But, with that said, the APM2 weighs 10.8g, whereas the M993 weighs 8.3g. Do the math. The APM2 actually has more force behind it. Mass has less to do with ballistic penetration of armor than velocity and bullet composition. For example, a .308 has significantly more mass than an M855 but the M855 will zip right through level III PE plates effortlessly while the .308 stops reliably. If you think that armor penetration can be reduced to simple mathematics of "more mass means more penetration", that would be... misguided. Now you're thinking: Tungsten carbide is stronger than tool steel, so it'll penetrate better. That's true. But only sometimes -- not always. If you've got a boron carbide plate, be very afraid of tungsten-cored rounds. But those generally aren't available to civilians anyway -- and, when they are, they're prohibitively expensive. Silicon carbide and alumina plates tend to perform against WC rounds just as well as they perform against steel. Yes, I was thinking exactly that because, well... it's true. Also, the rest of this paragraph is wrong in several areas. Explain why someone should be more afraid of tungsten rounds when using boron carbide; please be specific. Also, the notion that B4C plates aren't available to civilians is total crap. I can't make sense of the last line at all. In short, I'd reckon that most Level IV plates should stop M993, unless they're made of boron carbide. Again... what? Are you saying Boron Carbide is more vulnerable than other ballistic grade ceramics? Please elaborate. If you're rocking a steel plate, you're screwed in any case. I agree, even if you're not being shot at.

Yet, with that said, I don't see what people have got against AR500armor. They're pretty straightforward about what they offer, and it's actually really not bad. They're the furthest thing from deceptive; they're actually really honest... in other words, they're no RMA! (Sorry, couldn't help myself. Seriously, though...) I wouldn't say "really honest", but I would say "mostly honest". They have definitely played the weight loss game but overall, I agree with you. I'm surprised that some of the players in the industry haven't started to really take notice of the "lightest level IV 10x12" claim that RMA makes about their 8x10 inside a 10x12 rubber liner, and file a class action against them. View Quote |

|

|

|

[#17]

On .308 vs. PE:

Apples to oranges. The M855 will zip through a PE plate on account of the M855's tiny tool steel core. Show me a .308 with a tool steel core, and I'll show you something that will go through a PE plate like a warm knife through butter. ...But the differences between hardened steel and tungsten carbide projectiles are, on the whole, fairly insignificant when we're talking about SiC and alumina ceramic targets. There are a couple of caveats, but, generally speaking, I'd expect a solid Level-IV plate to stop the M993. If you read this PDF carefully, and note the fact that as little as 5.44mm SiC is capable of totally shattering an M993 round, you'll come to the same conclusion I have: A SiC Level-IV armor plate -- which is generally ~8mm SiC over 11+mm PE -- should handily stop the M993. (Let's not make the mistake of assuming that because some fragments penetrated the soft aluminum test-block, that they'd penetrate the backing layer of a ceramic plate. They'd be caught more often than not.) |

|

|

|

[#18]

On tungsten carbide vs. boron carbide:

Tungsten carbide projectiles have been known to trigger a phenomenon called amorphization in boron carbide. You can read a bit about it here. Long story short, what this means is that boron carbide's atomic structure is liable to degrade under sufficiently high pressures. WC projectile impacts are capable of generating such pressures. Thus, as WC-cored projectile impacts can rapidly degrade the atomic structure of boron carbide, the performance of boron carbide armor plates against WC threats is generally very poor. This is a well-known phenomenon; there are dozens of papers about it. It was first discovered when people started noticing that SiC and alumina plates performed well against WC threats, whereas B4C under-performed. ...So, yeah, what I'm saying is that boron carbide is more vulnerable to WC threats, and it has been shown (see below) that it doesn't perform well against M993. This phenomenon may, in fact, explain the XSAPI mystery. (What unknown projectile were they trying to protect against? Hmmmm...)

|

|

|

|

[#19]

On boron carbide availability:

Come on, you know as well as I do that 99% of the plates out there are alumina and silicon carbide. Besides Protech overstock, does anybody sell B4C plates to the civilian market today? I suppose I could be wrong... On AR500: I think they've always been straightforward. Everybody plays the weight game to some extent. But look at their Level-IV plate; they're not ashamed of the fact that it weighs something like 8lbs! They are what they are: The low-cost solution, for people who probably don't really need armor but want to have it anyway without breaking the bank. In that sense, I salute them. RMA is... well... let's just say that they're on the other side of that honesty/straightforwardness spectrum.

|

|

|

|

[#20]

Quoted:

On tungsten carbide vs. boron carbide: Tungsten carbide projectiles have been known to trigger a phenomenon called amorphization in boron carbide. You can read a bit about it here. Long story short, what this means is that boron carbide's atomic structure is liable to degrade under sufficiently high pressures. WC projectile impacts are capable of generating such pressures. Thus, as WC-cored projectile impacts can rapidly degrade the atomic structure of boron carbide, the performance of boron carbide armor plates against WC threats is generally very poor. This is a well-known phenomenon; there are dozens of papers about it. It was first discovered when people started noticing that SiC and alumina plates performed well against WC threats, whereas B4C under-performed. ...So, yeah, what I'm saying is that boron carbide is more vulnerable to WC threats, and it has been shown (see below) that it doesn't perform well against M993. This phenomenon may, in fact, explain the XSAPI mystery. (What unknown projectile were they trying to protect against? Hmmmm...) https://www.nap.edu/openbook/13157/xhtml/images/p37-002.jpg View Quote I was not aware of that and now I have learned something. My mistake was in assuming you were simply saying that B4C was an inferior strike face. It was not clear that you were saying B4C underperformed specifically vs tungsten. Thanks for sharing. |

|

|

|

[#21]

Quoted:

On boron carbide availability: Come on, you know as well as I do that 99% of the plates out there are alumina and silicon carbide. Besides Protech overstock, does anybody sell B4C plates to the civilian market today? I suppose I could be wrong... First part is correct but B4C plates are available from many, many vendors to anyone willing to pay the premium for them. On AR500: I think they've always been straightforward. Everybody plays the weight game to some extent. But look at their Level-IV plate; they're not ashamed of the fact that it weighs something like 8lbs! They are what they are: The low-cost solution, for people who probably don't really need armor but want to have it anyway without breaking the bank. In that sense, I salute them. Agreed. RMA is... well... let's just say that they're on the other side of that honesty/straightforwardness spectrum.

Very much agree. View Quote |

|

|

|

[#22]

I got a question via PM about commercial armor plate stopping M993, and I did mention a couple of caveats, so here goes:

-If the plates are reaction-bonded SiC, they probably won't stop the M993, even though they might stop the APM2 round. (This also goes, even more strongly, for reaction-bonded boron carbide -- which, interestingly, was the basis for military issue plates.) In the study I linked to, the WC-cored rounds went right through a RBSiC panel without any trouble at all. So, clearly, ceramic production method matters. I have some thoughts on why this might be the case, and it has nothing to do with hardness, but it's a fairly complex phenomenon and there's a 2000 character count limit... -If the plates are low-quality alumina, they will probably fail. This is because tungsten carbide projectile cores have a hardness of 1200-1500 (Vickers). Pure (99%+) alumina, the good stuff, clocks in at around 1700HV -- but <96% alumina, the cheap stuff, clocks in at around 1350HV. (On average.) So if armor plates use cheap alumina, there's a good chance that the ceramic will be softer than the projectile's penetrator, and that always makes for terrible performance in thin systems. The cheap alumina might be sufficient to stop APM2 rounds, though. Ceramics of hardness around 1300HV have been shown to perform extremely well against steel rounds. (For comparison's sake, SiC is around 2100HV, and hot-pressed B4C is around 3000HV... which is why everybody was initially very confused by its awful performance vs. WC rounds! RBSiC and RBB4C are both around 1500-1800HV. Tool steel is generally around 700-850HV.) |

|

|

|

[#23]

...So the M993 is a good test of "quality." Cheap reaction-bonded SiC plates, and ultra-cheap low-quality alumina plates, stand a very high chance of failing against that round. But SiC and Alumina plates of solid construction and high quality will stop the M993 every time. In fact, the APM2 round may even be more dangerous to said plates, on account of its greater mass and the much greater length of its steel penetrator.

Interestingly, B4C plates are the lightest and most expensive of all, but would also fail. So I suppose we could say that the M993 tests for quality on a U-shaped curve. If you're facing anything but WC rounds, B4C ceramic armor is the best stuff you can buy. LayerUp: If you don't mind my asking, where can one buy B4C plates these days? (Besides Protech, that is.) I'm actually rather curious about this, because reaction bonding tech is still under patent, and I'd be pretty surprised if anybody were hot-pressing B4C ceramics for armor purposes. It's such a slow and expensive process. |

|

|

|

[#24]

AR500 had a batch of plates that Winchester "white box" 5,56mm went through like butter.

IMHO, all the shit-talking, especially on P&S, had to do more with CQ with that particular brand than anything else. |

|

|

|

[#25]

Quoted:

Don't tell me I gotta teach y'all math again. First of all, the regular test velocity of the APM2 is 2880 fps. M993 tests at 2980 fps. But, with that said, the APM2 weighs 10.8g, whereas the M993 weighs 8.3g. Do the math. The APM2 actually has more force behind it. Now you're thinking: Tungsten carbide is stronger than tool steel, so it'll penetrate better. That's true. But only sometimes -- not always. If you've got a boron carbide plate, be very afraid of tungsten-cored rounds. But those generally aren't available to civilians anyway -- and, when they are, they're prohibitively expensive. Silicon carbide and alumina plates tend to perform against WC rounds just as well as they perform against steel. In short, I'd reckon that most Level IV plates should stop M993, unless they're made of boron carbide. If you're rocking a steel plate, you're screwed in any case. Yet, with that said, I don't see what people have got against AR500armor. They're pretty straightforward about what they offer, and it's actually really not bad. They're the furthest thing from deceptive; they're actually really honest... in other words, they're no RMA! (Sorry, couldn't help myself. Seriously, though...) View Quote How many screen names is this for you? |

|

|

|

[#26]

Quoted:

How many screen names is this for you? View Quote "ThrottleUp" was banned for registering using a proxy email service, to post to a thread where (a) a man was doxed, (b) legal action was threatened, and (c) he was right. Not unreasonable, surely? Anyway, I'm here to contribute, but must insist on remaining anonymous. Got a problem with that? If so, PM me. Let's not derail this thread further. |

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.