|

Posted: 5/21/2024 2:56:23 PM EDT

[Last Edit: giantpune]

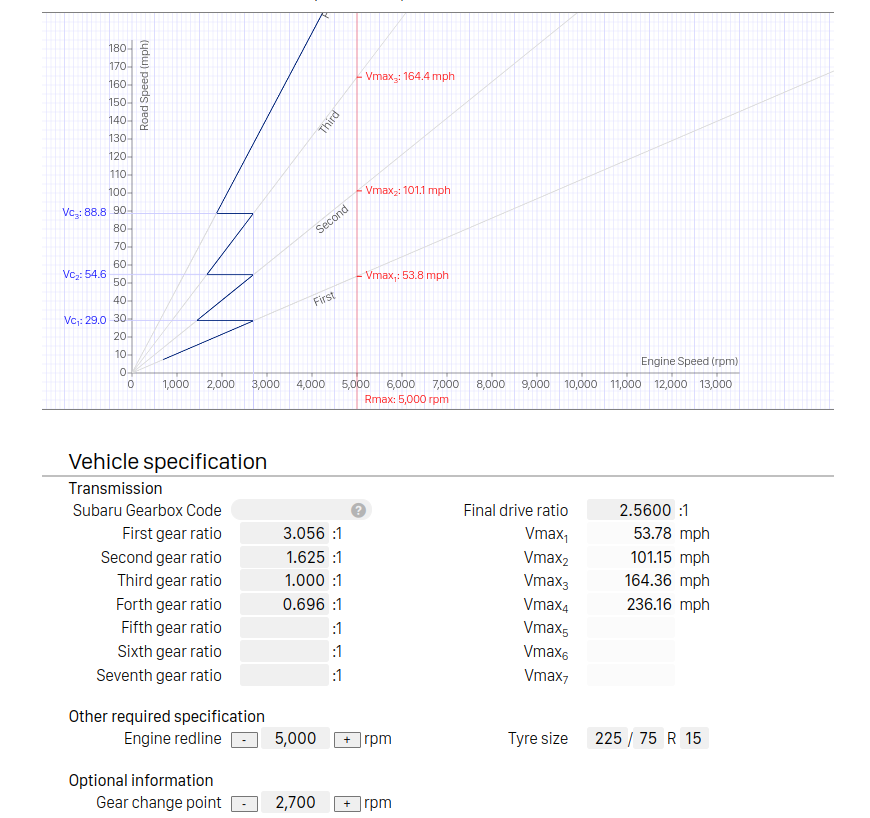

EDIT:

I secured a 12 bolt rear axle for this truck (82 C-10). Gonna clean it up and use it. I've settled on 3.73 gears in an eaton truetrack carrier. Cleanup starts around post #25. Original post: The saga on my 82 C-10 continues. In this chapter, I'm looking to do something with the rear axle. It's still in its stock form. 10 bolt housing and based on spinning the wheel around and watching the yoke, I have deduced its the 2.56:1 ratio, open diff. The transmission has been upgraded to a 700r4, which has a 3.056 1st gear, 0.696 overdrive, and a lockup torque converter. Stock tire size on this truck is 225/75r15, which is 28.29" tall. If you plug those numbers into a calculator, when this truck is in overdrive and the torque converter locked up, 2000 RPM is 92MPH. With a 5000 RPM redline, its geared to hit 236 MPH.  Great for gas mileage, I guess. It just idles around town, and even on the highway Never have to get over 1800 RPM. But also a tad gutless. Great for gas mileage, I guess. It just idles around town, and even on the highway Never have to get over 1800 RPM. But also a tad gutless.My immediate goal is to get a more peppy gear ratio. Maybe around 3.5 or 3.73. At the same time, I would like to swap it from an open diff to some form of locking diff. Use case is a street truck used to lug crap around town. It will see the occasional doughnut. It will not be getting slicks and hitting the strip. Motor is a mildly built 350 with under 400HP. What say the hive on this one? I think the cheap route would be rebuild what I have here. If I do that, what does the shopping list look like? I haven't ever done a chevy rear end. I have no clue what all comes in which kits and what you have to buy separately like bearings, seals, and shims. And there are several different types of lockers. Which one for a street truck that will get hammered on every now and again? Local junk yard did not have any 10 or 12 bolt that would bolt right into this truck. Everything would require welding, and probably rebuilding. I had also looked at the full axle kits setup for a ford 9". Those run $3k and come with new drum brakes and axles and everything in between and will bolt right in. I would probably be on the hook for a new driveshaft. What else is there out there? If there's somewhere I could buy an already complete setup that would drop in, and be less than $3k, that would be cool. |

|

|

|

|

I would find a mechanic that knows how to set up a rear diff, buy all the parts and drop it off. Yukon 3.73 gear with their posi carrier, upgrade to a 30 or 33 spline axles and go have some fun. It isn't hard to do but does require some tooling that a diy just wouldn't make much sense if you had to buy it all.

|

|

|

|

|

For your intended use and the hp your 350 is making, the 10-bolt will be fine! No need to spring for a 12-bolt or 9” Ford, in my opinion!

I personally feel that a 3.73 rear gear is a perfect street gear, especially with an OD tranny like you have. Theres lots of different “posi” or limited slip center sections to pick from. You’ll need someone with specialty tools to set up the teeth engagement, backlash, etc on the ring and pinion. Have fun! |

|

|

|

|

Personally, I would go with a 3.42 rear end with your trans and wheel diameter, but I like to get on the highway to go places as well as around town. If you want to tow or worry more about straight line speed go 3.73.

I put in an Auburn LSD in my 85 3.08 geared C10 with a SM465 trans and absolutely love how it locks up. Doesn't get one wheel going first like an old spin locker, and makes it predictable to slide around in the rain...

|

|

|

I like pants with pockets.

|

|

Building a GM rear end, or most any hypoid axle, is no task for a novice. I've done it multiple times, and hated every single one. It's not that it's very hard, it's just very tedious and you'll pull your hair out wondering if you have the tooth mesh pattern just right.

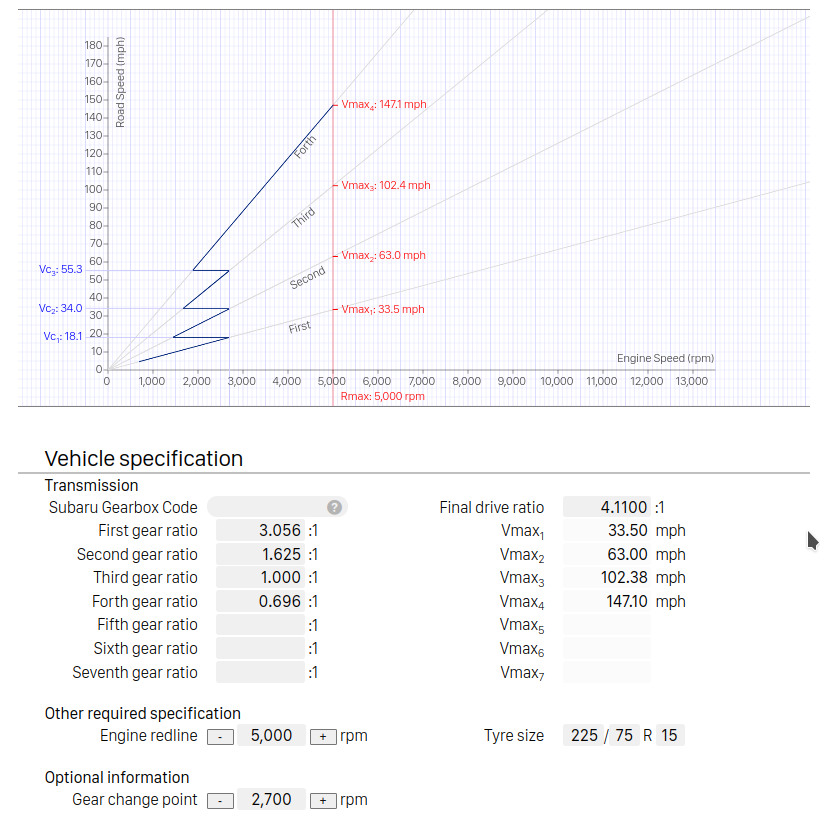

For your axle, to change the ratio above a certain number, as best I can recall, it's 2.73, you're going to need a whole new carrier anyway. I may be off on the carriers, it's been a looooong time since I built my last 12 bolt. Or 10 bolt. As long as you're doing a whole new carrier, your choices for LSD are wide open. For the use you describe, I'd go with a clutch type LSD or MAYBE a Torsen-type. As far as gears go, with that OD, and assuming no super high stall TC, a 3.91 is going to be equivalent on the highway to what a 2.73 would have been with any of the old 3-speed autos or 4 speed manuals, all of which had a 1:1 high gear. Even a 4.11 would not be bad on the highway, especially with those relatively tall tires, and it will be a dramatic difference in performance and driving feel. I spent my formative years driving a '67 F-body with first 3.08 gears and then later 3.55's on ~24" tires with a M-21 4-speed. Always wished I had 3.91's in the car at least. |

|

|

|

|

Using summitracing, my cost to DIY would be about $1200. Thats the gears, LSD, install kit, fluid, and a couple tools I dont have. I already have a shop press and a million different types of measuring instruments. Watched about 6 hours worth of different guys showing how to do these on youtube, from garage goobers to a 2hr lecture from an auto shop teacher. It doesn't look like something that scares me away.

I did call up the local garage that specializes in working on cars from before 2000. Lady said they just did the exact same job in an 83 C-10 and read me off the invoice. $2100 and change, assuming the axles and outer bearings and seals are good. They used the same yukon parts off summit that I'd be getting. So cost would be $900 for me to not have to do it, and to get whatever sort of warranty they put on labor. |

|

|

|

|

Suggest finding a 3.73 out of a more modern machine (built in last twenty years) that has rear disc brakes.

|

|

|

The rules are simple: they lie to us, we know they're lying, they know we know they're lying, but they keep lying to us, and we keep pretending to believe them.

|

|

Came here to post. A 3.73 and a posi will be what you seek.

what I haven't seen posted here is to call Eaton. They originally made the posi and gears so they will be better equipped to get you going down the right path. You will need a 3 series carrier, gears, bearing kit and a press. Buy all your parts and then have a shop do the work. You can burn things up if it isn't set up correctly. Good luck and post a video of the occasional donut! |

|

|

Grab it at the bottom!

|

|

Originally Posted By Freiheit338: Suggest finding a 3.73 out of a more modern machine (built in last twenty years) that has rear disc brakes. View Quote The local junk yard is full of newer things with disc brakes. $150 for a complete rear axle. But nothing is drop in. I would have to cut stuff off and then weld on new shock mounts. Then hope whatever one I picked was not fucked up and needed rebuild. I'm not really sure disc brakes on the back of this truck would make a bit of difference performance-wise. The drums already have enough force, I can lock up the wheels and lay down skid marks. The only reason I'd switch to discs is for ease of maintenance. Drum brakes are just a pain in the taint to work on compared to discs. |

|

|

|

|

Originally Posted By giantpune: Using summitracing, my cost to DIY would be about $1200. Thats the gears, LSD, install kit, fluid, and a couple tools I dont have. I already have a shop press and a million different types of measuring instruments. Watched about 6 hours worth of different guys showing how to do these on youtube, from garage goobers to a 2hr lecture from an auto shop teacher. It doesn't look like something that scares me away. I did call up the local garage that specializes in working on cars from before 2000. Lady said they just did the exact same job in an 83 C-10 and read me off the invoice. $2100 and change, assuming the axles and outer bearings and seals are good. They used the same yukon parts off summit that I'd be getting. So cost would be $900 for me to not have to do it, and to get whatever sort of warranty they put on labor. View Quote Cursory search of Summit doesn't show any Torsen-type diffs (Eaton Tru-Trac, Nitro, etc) available for your axle, which is a little surprising. The Yukon is a clutch-type, so you want to be DARN SURE you have the right positrac additive for the oil that matches the Raybestos clutches in it. Back in the day, the little bottle of GM spec posi additive was actually whale oil, but that has been a few decades, I'm sure there is something else now. If you don't use the correct additive, you will burn the clutches up with quickness and maybe get some chatter in turns along the way. Every US-built car with a clutch type diff, which was all of them from the 1960's through probably the 1990's or later, came with this additive from the factory. I'd also suggest that you work yourself up a speeds in gears graph for each axle ratio, and think about your daily drive in terms of it. I still say a 4.11 is the way to go with your combo. |

|

|

|

|

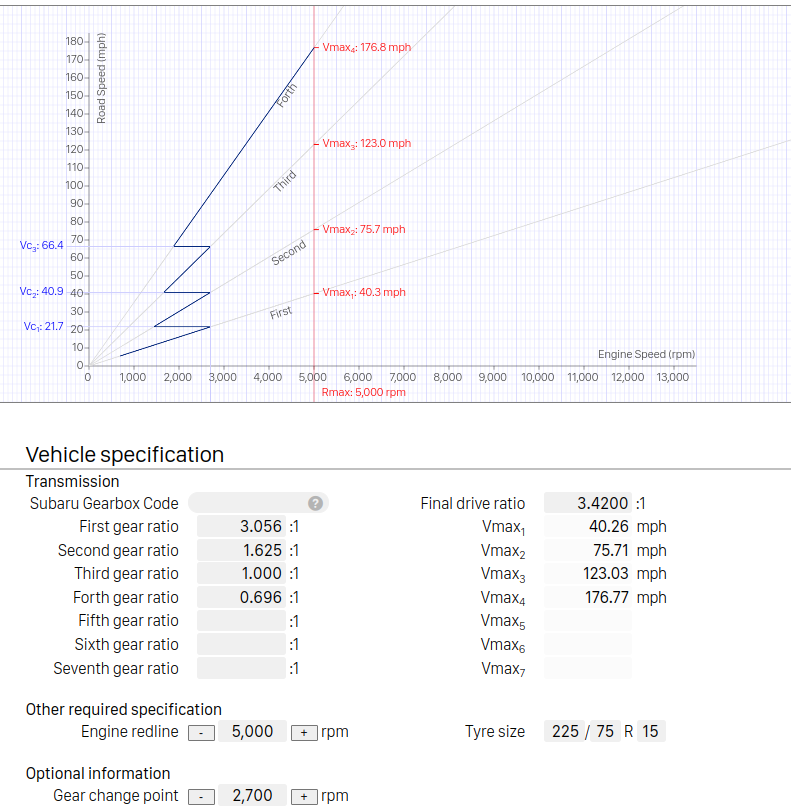

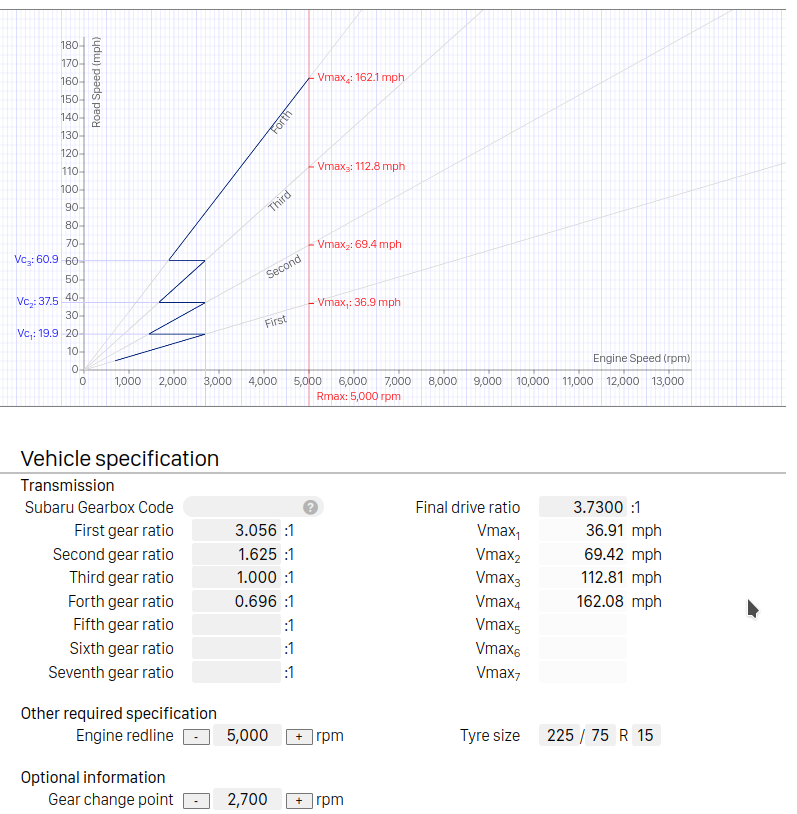

Originally Posted By VVinci: Cursory search of Summit doesn't show any Torsen-type diffs (Eaton Tru-Trac, Nitro, etc) available for your axle, which is a little surprising. View Quote This one doesn't count? https://www.summitracing.com/parts/etn-912a556 And I found a decent calculator that accepts most of the parameters and graphs RPM ranges and vehicle speed. I could not find one that also had any sort of input for torque converter slippage. So far, this is the best I could find. I entered 2700 RPM for the shift points, which is a tad higher than the automatic transmission would normally do while just puttering around town. It will obviously be higher when you're romping on it a bit. 4.11:1 will be over 2000 rpm just cruising down the highway at 65mph. 75mph would be 2500 RPM. I like the highway RPMs of the 3.73 chart.     |

|

|

|

|

If you're close enough to Summit, go hit the scratch and dent shelves for all the parts you want for your rebuild. Tons of GM 10 bolt gear sets and bearing kits usually on there because nobody wants that junk

We built out the 9" in my buddies 65 C10 for less than half what it was going to cost by doing this. |

|

|

Arftard Outbreak Response Team:

Multilevel Marketeer |

|

Originally Posted By giantpune: This one doesn't count? https://www.summitracing.com/parts/etn-912a556 And I found a decent calculator that accepts most of the parameters and graphs RPM ranges and vehicle speed. I could not find one that also had any sort of input for torque converter slippage. So far, this is the best I could find. I entered 2700 RPM for the shift points, which is a tad higher than the automatic transmission would normally do while just puttering around town. It will obviously be higher when you're romping on it a bit. 4.11:1 will be over 2000 rpm just cruising down the highway at 65mph. 75mph would be 2500 RPM. I like the highway RPMs of the 3.73 chart. https://iili.io/JibsBFS.png https://iili.io/Jibsx9e.png https://iili.io/JibsnS9.png https://iili.io/JibsCc7.png View Quote Got a link to that calculator? |

|

|

|

|

|

|

Originally Posted By paul463: Got a link to that calculator? View Quote https://legacypic.uk/transmission/graph.php |

|

|

|

|

Originally Posted By giantpune: This one doesn't count? https://www.summitracing.com/parts/etn-912a556 And I found a decent calculator that accepts most of the parameters and graphs RPM ranges and vehicle speed. I could not find one that also had any sort of input for torque converter slippage. So far, this is the best I could find. I entered 2700 RPM for the shift points, which is a tad higher than the automatic transmission would normally do while just puttering around town. It will obviously be higher when you're romping on it a bit. 4.11:1 will be over 2000 rpm just cruising down the highway at 65mph. 75mph would be 2500 RPM. I like the highway RPMs of the 3.73 chart. https://iili.io/JibsBFS.png https://iili.io/Jibsx9e.png https://iili.io/JibsnS9.png https://iili.io/JibsCc7.png View Quote When I searched, I just put in the year and make of your truck, didn't have the specific axle specs to go by. I would take a Tru-Trac over any clutch style diff, BUT be aware that it will be more aggressive than a clutch diff. Torsens are great for steering at the limits of adhesion in a turn! Think carefully about the powerband of the cam you have in the truck. Based on what you have said, I'm going to guess its around 2500-5500 rpm. In contrast, most modern cars have engine power curves designed to yield a wider, flatter powerband with some reaching max torque or 90% of it well prior to 2000 rpm. The Ford Ecoboost V6s are a case in point - you can drive them like a diesel, never exceeding 2200 rpm, all day and keep up with or beat traffic while getting great MPG. Your torque curve will fall off much more sharply below 2k than that of most modern engines, despite your advantage in displacement. So, for good driving feel, you can go two ways - power right now, regardless of trans gear, or power on kickdown, while accepting more frequent kickdowns and some reluctance to do much without a kickdown. The 4.11 will give you the former, the lower numerical gears will move you more and more toward the latter. Being right on the edge of the powerband at cruise, the 4.11 is going to give you more of an urgent, alive feel to the driving characteristics that some don't like - I do. As you go lower numerically, the feel will become more relaxed. Look carefully at where 4-3 and 4-2 kickdowns will put you in the powerband with each axle ratio. This is especially useful if you do a lot of passing on 2 lane roads. Envision a 50 MPH 4-2 kickdown with each gear - where do you land in the powerband, and how many revs left before an upshift? The 4.11 is probably more like a 4-3 kickdown, I can't see your graphs as I post and don't recall where everything lands. Is 4th useful at around town speeds, or is it a highway-only gear with the axle chosen? 4.0 Jeeps have this problem with 5 speed manuals, 5th can easily become useless in real terms. Ditto for the 9 speed modern Cherokee, some of those have never seen 9th gear in 100k miles. Just some food for thought. |

|

|

|

|

Originally Posted By VVinci: I would take a Tru-Trac over any clutch style diff, BUT be aware that it will be more aggressive than a clutch diff. Torsens are great for steering at the limits of adhesion in a turn! Think carefully about the powerband of the cam you have in the truck. Based on what you have said, I'm going to guess its around 2500-5500 rpm. In contrast, most modern cars have engine power curves designed to yield a wider, flatter powerband with some reaching max torque or 90% of it well prior to 2000 rpm. View Quote Regarding turning, this is about my biggest gripe about the squarebody trucks. Turning radius sucks. So we can probably ignore any concerns about how the rear end will need to perform in a tight corner. The steering geometry hits the limits well before the truck can make anything that would be considered a sharp turn.  The camshaft in this motor is the chevy one they used in the L46 and L82 corvettes. Mr. Clean dyno'd those engines and put some charts up on the youtube (https://youtu.be/Tz7CM9_0QJU?t=388). My setup has aluminum heads and a dual plane aluminum intake. I'm assuming more power with a similar sort of power band. For cruising down the highway, it only takes like 87HP to keep the truck moving. I think I'd like to have the option to cruise with a lower RPM. I always have the option to unlock the torque converter or kick it down a gear if I want to get the RPMs up. Regarding the question about 4th being usable around town, you dont really get an accurate picture of it from those graphs, because this is an automatic. The torque converter doing its thing means the engine RPMs will fluctuate for a given input shaft speed. And with a 700r4 torque converter, its like there's a gear between 3 and 4, when its in 4 with the converter not locked. I think with most of those ratios between 3 and 5, the highest gear will be usable around town without feeling gutless. Thats part of the magic of the torque converter. Even with a 2.56 rear end, the torque converter doing its thing makes 4th gear drivable around town. |

|

|

|

|

Originally Posted By giantpune: Regarding turning, this is about my biggest gripe about the squarebody trucks. Turning radius sucks. So we can probably ignore any concerns about how the rear end will need to perform in a tight corner. The steering geometry hits the limits well before the truck can make anything that would be considered a sharp turn.  The camshaft in this motor is the chevy one they used in the L46 and L82 corvettes. Mr. Clean dyno'd those engines and put some charts up on the youtube (https://youtu.be/Tz7CM9_0QJU?t=388). My setup has aluminum heads and a dual plane aluminum intake. I'm assuming more power with a similar sort of power band. For cruising down the highway, it only takes like 87HP to keep the truck moving. I think I'd like to have the option to cruise with a lower RPM. I always have the option to unlock the torque converter or kick it down a gear if I want to get the RPMs up. Regarding the question about 4th being usable around town, you dont really get an accurate picture of it from those graphs, because this is an automatic. The torque converter doing its thing means the engine RPMs will fluctuate for a given input shaft speed. And with a 700r4 torque converter, its like there's a gear between 3 and 4, when its in 4 with the converter not locked. I think with most of those ratios between 3 and 5, the highest gear will be usable around town without feeling gutless. Thats part of the magic of the torque converter. Even with a 2.56 rear end, the torque converter doing its thing makes 4th gear drivable around town. View Quote The more aggressive LSD will actually push your nose wide (more understeer) until it breaks traction in the rear. It will be entertaining to play with. Notice how Mr Clean's charts cut off at 3k rpm? He's either using a water brake dyno or an electric dyno that doesn't like low speeds. Both get unstable at lower rpm, and you see a lot of older dyno tests that cut off this high. The artifact in the graphs at the extreme left side suggests that might be the situation. In any case, the point is that the power curve will drop pretty fast below 2500 rpm. You actually have a milder cam than what I was picturing, but depending on what heads you have and the porting job, if any, the band could move up some. If the heads have really been hogged out or came with large ports, velocity may be slow enough at low rpm that torque falls off faster than these graphs suggest. Another way to look at this is the slope of the HP curve. By 3500 rpm, it is falling off at roughly a 90 HP/1000 rpm clip. It will only steepen as revs fall. That means that at 2000 RPM, you're making less than 125 HP, less 10-15% drivetrain loss, so right around 105-110 WHP. You'll have very little torque margin at that speed IF your road load of 87 HP is accurate. WRT to TCs, my background is in transmissions, and I have characterized their performance on a dyno and/or in a car uncounted dozens of times, so I understand what you mean. It's just easier for discussion board purposes to talk about the trans as if it were a manual rather than bringing in K factor, stall speed, quasi-static performance (the SAE standard TC test takes place at fixed input speeds) vs actual real world dynamic performance (the entire curve shifts around on some TCs in dynamic situations, not so much for others). All that said, I'd go at least 3.73's and more likely 3.91's. You only want to do this once, and you're dealing with a heavy vehicle that has relatively tall tires. In a F-body of that vintage, there's no question I'd go with 3.73s, but it is much lighter, better aero, and shorter tires. FWIW, 87 HP is a LOT of road load in modern terms. |

|

|

|

|

Originally Posted By giantpune: The saga on my 82 C-10 continues. In this chapter, I'm looking to do something with the rear axle. It's still in its stock form. 10 bolt housing and based on spinning the wheel around and watching the yoke, I have deduced its the 2.56:1 ratio, open diff. The transmission has been upgraded to a 700r4, which has a 3.056 1st gear, 0.696 overdrive, and a lockup torque converter. Stock tire size on this truck is 225/75r15, which is 28.29" tall. If you plug those numbers into a calculator, when this truck is in overdrive and the torque converter locked up, 2000 RPM is 92MPH. With a 5000 RPM redline, its geared to hit 236 MPH.  Great for gas mileage, I guess. It just idles around town, and even on the highway Never have to get over 1800 RPM. But also a tad gutless. Great for gas mileage, I guess. It just idles around town, and even on the highway Never have to get over 1800 RPM. But also a tad gutless.My immediate goal is to get a more peppy gear ratio. Maybe around 3.5 or 3.73. At the same time, I would like to swap it from an open diff to some form of locking diff. Use case is a street truck used to lug crap around town. It will see the occasional doughnut. It will not be getting slicks and hitting the strip. Motor is a mildly built 350 with under 400HP. What say the hive on this one? I think the cheap route would be rebuild what I have here. If I do that, what does the shopping list look like? I haven't ever done a chevy rear end. I have no clue what all comes in which kits and what you have to buy separately like bearings, seals, and shims. And there are several different types of lockers. Which one for a street truck that will get hammered on every now and again? Local junk yard did not have any 10 or 12 bolt that would bolt right into this truck. Everything would require welding, and probably rebuilding. I had also looked at the full axle kits setup for a ford 9". Those run $3k and come with new drum brakes and axles and everything in between and will bolt right in. I would probably be on the hook for a new driveshaft. What else is there out there? If there's somewhere I could buy an already complete setup that would drop in, and be less than $3k, that would be cool. View Quote I have overdrive and the 4.56 gears are PERFECT. No need for a Locker unless you are STRICTLY mud racing. The modern 8.6" 10 bolt is plenty strong for small block power. mine has 220,000 miles on it, no problems. Gasoline is shit here, maximum is 90 Octane at the pump, so I limit to 11 pounds manifold pressure. |

|

|

|

|

Welp, slight change of plans. A 12 bolt rear axle out of a suburban fell into my lap. The width is correct, as well as all the shock mount locations and lugnut pattern. It should be a direct bolt-in. Its only a 3.08:1, and still an open diff.

My plan for the guts is still the same. 3.73 and a limited slip carrier. Now I get to do it with more heavy duty parts. |

|

|

|

|

Might be worth checking with a dedicated driveline shop to compare pricing

|

|

|

BikerNut:

Normal people like motorcycles. Real people like motorcycles. People who don't like motorcycles are just... weird. |

|

I spent last weekend doing some of the lower cost stuff to my new 12 bolt rear axle. Degreased, pressure washed, degreased again, pressure washed again, then sand blasted it. Not completely stripped down, but more than good enough. I found a bunch of markings from the manufacturer that were buried from years of sludge and undercoating. Then I painted it with some of my Eastman's black paint I use on all my under the car related stuff.

The tube says KDA 237W72. That decoded to a 3.40:1 open diff. I spun it around and counted, and it turned out to be correct. Still not quite what I was hoping for, so the plan moves forwards. I got a family member who was wanting a set of 3.40 gears, which works out perfectly for him. I started disassembly of the thing, down to pulling the axle shafts out to see how they looked where the bearings and seals ride. They're good enough to reuse. My shopping list so far looks like a yukon kit with 3.73 gears and all the bearings, seals, and crush sleeves in one convenient SKU. Then an eaton truetrac setup. Mostly cause I'm lazy and neglectful. I dont want to ever have to think about the clutches or the fluid inside it. And then a bunch of "while you're at it" type of parts. New guts for inside the drum brakes, flexible brake hose. And I may pony up to swap to some QA1 shocks. https://www.summitracing.com/parts/yga-10627 https://www.summitracing.com/parts/etn-913a315 Next steps will be swiping the credit card to get the crap ordered. |

|

|

|

|

I also recommend a 3.73 and posi.

3.55 isn't saving you much in fuel, and if you did more highway I'd say 3.08s. My b body (also with a crystal ball differential) really woke up switching to 3.73s from 3.08s. |

|

|

Seriously, a tractor dealer from Possum Trot, KY has to explain this to you, a lawyer? - JPL

WTB: Glock 17 gen 2. SN CAF 895 Win if you can, lose if you must, but always look good for the crowd. |

|

Not an exact match (5 lug to six lug ect), but I swapped my 88 4x4 suburban rear axle for a 2005 silverado disk rear end and it was stupid easy. Minimal grinding and welding. Had to install new spring pads and shock mounts, and lengthen the brake line. Gave me rear disks, parking brake (easy mod), locking diff, and the ratio I wanted. Moderate increase in strength, went from an 8.5 to the newer 8.6 ring. Even the u-joint was the same size and location. Biggest change other than the upgrade was the axle is a total of 4 inches wider, which was something I wanted anyway. The complete axle with parking brake cables was $150 at the yard. About $100 in parts (axle pads, brake line, e brake fitting) amd some welding and I was done.

|

|

|

|

|

I use a Powertrax (NOT a Lok-rite) and it's perfect.

You never know it's there till you need it and it's function is flawless. Mine is 3.73 with a 700 R4 and it's about right with a ZZ4 350. |

|

|

I won't be wronged. I won't be insulted. I won't be laid a-hand on. I don't do these things to other people, and I require the same from them

|

|

|

|

I don't know where in Ga. you are but Southern Gear over off Atlanta rd. and 285 is a decent shop for both parts or having them build it. They do want it loose to build. Also Rockauto has cheap gear sets for stuff that is not a high horsepower racecar. I picked up a 4.11 for my sons Lincoln for a little over $100

|

|

|

RIP Jeff Reed. Tennessee Squire, Ga. Carry member, NRA,Non-puking 72 ounce drinker 2 of 6 Norcal call sign, Forgotten.

|

|

And the shitbox truck rides again. I got the universal joint all figured out. Drive shaft back in. Brakes bled.

I took it for its maiden voyage. Everything worked as it should and we made it back home without a tow truck, no leaks and no noises. My speedometer says 80mph while the GPS says 66MPH. I reckon that means I can figure out which speedometer gear is in it and hope I can just order one with about 21% more teeth on it. |

|

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.