|

Posted: 11/18/2015 9:34:37 PM EDT

So, I was asked about making a thread with all the parts and pieces need to build a PID for controlling a lead casting furnace, so here it is.

What it is, A PID is a digital thermostat that will allow You to control the temperature of Your casting pot. No guessing, no adjusting, just simply program it to the temp You want. Also great for keeping track of what temp works best for a certain mould or alloy.

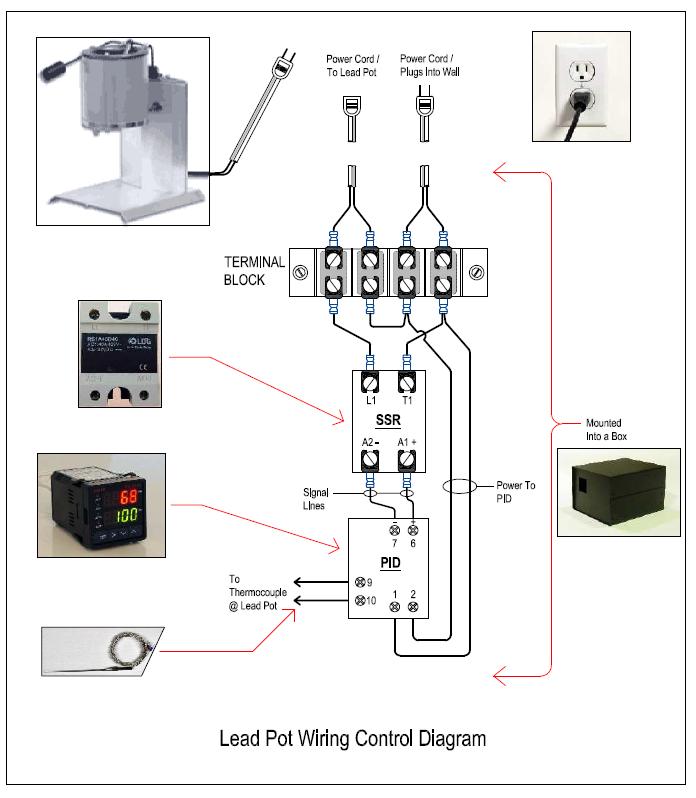

I found ALOT of good info at CastBoolits, PID schematic Wiring a PID Building a PID So You can see the list of parts in the other thread. If I did it again, I'd order the stuff from Amazon, cheaper, and no 3 weeks or more waiting. Here's the big item's, the rest is in the other thread, just little stuff. PID Box A little bit bigger of a Box SSR Fuse K-Type Thermocouple Terminal Strip Power Cord ON/OFF Switch Power Indicator Cord Fitting Some Item's are optional, depending on how You want to build Yours. You'll need 5' of 12GA and 5' of 16GA wire ()Red, Green, Black, White)( crimp on connectors, machine screws etc.... Here is the wiring diagram I used to wire Mine with.

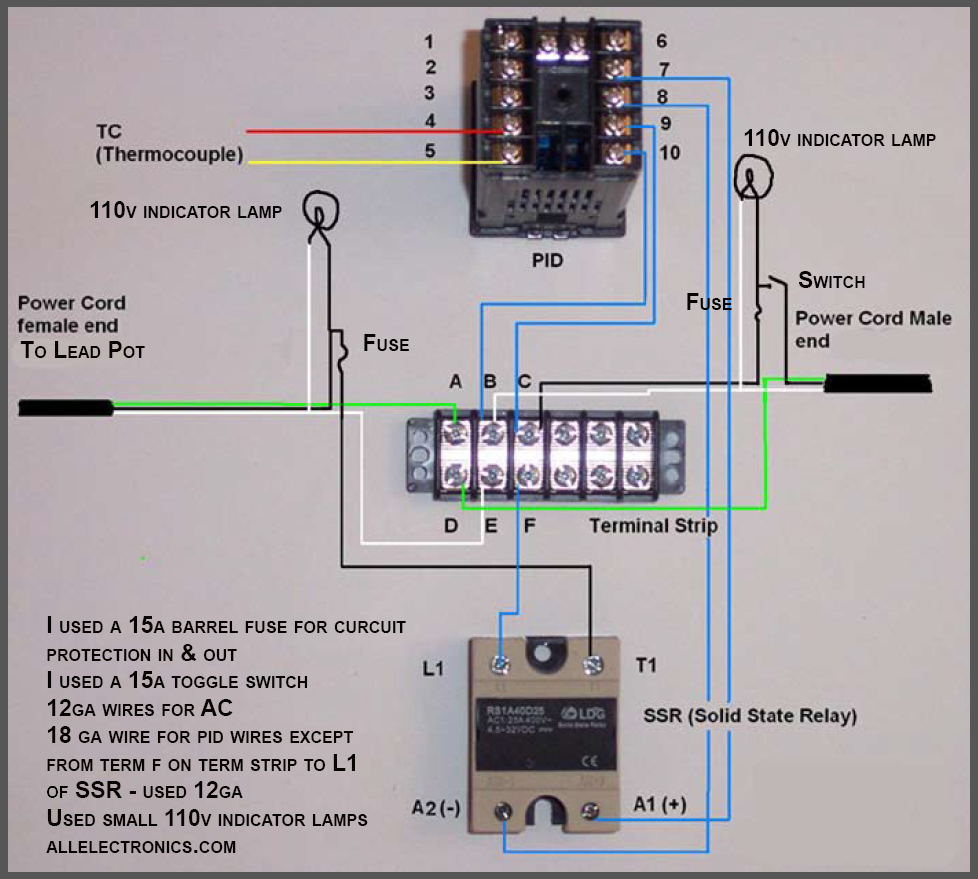

I used this diagram to wire the Switch, indicator light and fuse.

Pics of Mine inside, I left the wires long, I can remove each piece and unwire/wire it outside the box. Easy replacement.

Here is a shot of the back of Mine, I chose to install an outlet. I think the PID can control two units. I may be wrong on that, I just don't like the idea of a "pigtail" hanging out of the box.

|

|

|

|

|

More to come.

Done for Tonite, I will edit anything else I got to this, Tomorrow. |

|

|

|

|

In for more details.. any chance you could give rough estimates of costs?

I have not spent a ton of time casting.. But I do know I hate the Lee bottom pours. Dumped it and got the RCBS. Very nice but very expensive. Seems to regulate temp better too but maybe not as good as your contraption. A head to head cost estimate of yours vs the better furnaces will help new guys thinking of diving in I think. Thanks for detailed post! |

|

|

|

|

After completing the write up on this project, can you make a eddy current case mouth annealer with a programmable timer and do a similar how to write up?

|

|

|

|

|

I also built this setup and it works great!

The top (on) position bypasses the controller and just applies voltage to the pot to quickly heat up your lead. Then when the temp gets near your setpoint you switch to the bottom (on) position for the controller to take over. Since the controller is fuzzy logic it learns the best way to control the temperature (as I understand it) so it works better as you use it. |

|

|

NRA Life Member

Second Amendment Foundation Member |

|

Originally Posted By djryan13:

In for more details.. any chance you could give rough estimates of costs? I have not spent a ton of time casting.. But I do know I hate the Lee bottom pours. Dumped it and got the RCBS. Very nice but very expensive. Seems to regulate temp better too but maybe not as good as your contraption. A head to head cost estimate of yours vs the better furnaces will help new guys thinking of diving in I think. Thanks for detailed post! View Quote All the stuff listed above comes out to $90.00 from Amazon, add wire and Buttsplices, outlet, cover, I bet it could be done for $110.00. A lot of People use this for Their Lyman, Lee, RCBS, Magma, Lubrisizer's, Powder Coat oven, from what I have read. I believe it could even be rigged to a gas valve, if You knew what You were doing. |

|

|

|

|

Originally Posted By drfroglegs:

I also built this setup and it works great! The top (on) position bypasses the controller and just applies voltage to the pot to quickly heat up your lead. I just run Mine through the SSR, it stays on full blast till it gets to temp, then regulates itself. Then when the temp gets near your setpoint you switch to the bottom (on) position for the controller to take over. Since the controller is fuzzy logic it learns the best way to control the temperature (as I understand it) so it works better as you use it. View Quote I got My pot up to 750 by the Lyman Thermometer, then turned on the PID, hit the "learn" button, and it programs itself to the Lee lead pot. Whenever You move it to another device, rehit the "learn" program, it will teach itself the best way to use whatever it is controlling to achieve the programmed temperature. |

|

|

|

|

Originally Posted By pepe-lepew:

After completing the write up on this project, can you make a eddy current case mouth annealer with a programmable timer and do a similar how to write up? View Quote Been there, KINDA did that. DIY Annealer

|

|

|

|

|

Global Warming Hoax Skeptic before it was cool

|

Set the toggle to keep this thread out of the archives.

ChevelleDave, any time you want to find this thread, click on My Topics in this forum, and it will be there. Thanks for sharing this info. |

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

|

You are Welcome.

|

|

|

|

|

That's awesome.

|

|

|

|

|

Excellent thread Dave! This is the reason AR15.com remains at the top of the reloading forums. "Helpful" here is beyond the usual expectations at gun forums....the toggled threads here, that keep references permanent, is the key, which means that it's worth the effort to create and post such a thread as this, so skilled people like Dave will. As for casting, that's the next frontier for me, waiting for my coming retirement (pipe dream at the moment), can't wait!

Great diagrams & pictures, BTW, Dave! Makes it all very clear, thanks for the effort! |

|

|

|

|

Thank You G.

|

|

|

|

|

Global Warming Hoax Skeptic before it was cool

|

|

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

|

http://www.amazon.com/gp/product/B0087O6S2A?keywords=pid%20controller&qid=1448037258&ref_=sr_1_1&s=industrial&sr=1-1

You need a chassis box, some cordage, and a thermocouple. A Type K is adequate. I use a short round cord cut in half to get a male (power in) and female( plug for device) with nice molded cord ends. The PID controllers are pretty standard. |

|

|

|

|

Kool,

|

|

|

|

|

So, I wanna add a T/C wall mount plug and socket, but cant seem to find a decent set that are the proper metals.

There is a lot of false advertising from what I see, companies advertising them as TYPE-K, instead of K-TYPE. Anyone have a good source?[sup][/sup] |

|

|

I just gotta ask........

|

|

Thank you, I'll go and check them out.

|

|

|

I just gotta ask........

|

|

Okay so I found them at Aubur Instruments, there's a couple different kinds I will linked to.

Panel mount mini connector Panel mount many connector Round And if you want just a panel mount socket alone, Panel mount socket If you're building a PID, or one of the homemade case Annealers, check this place out. Aubur Instruments, seems like they have everything that would be needed, good prices and the ship from the US. |

|

|

I just gotta ask........

|

|

Auber is a very good company to deal with, and their service is impeccable. I never considered them for annealer parts, thanks for the tip Dave!

|

|

|

|

|

I would move the heat sink part of the SSR outside of the box. Those relays do make some heat and you have it trapped inside the box

|

|

|

|

|

Originally Posted By jamie930:

I would move the heat sink part of the SSR outside of the box. Those relays do make some heat and you have it trapped inside the box View Quote SSRs do generate some heat, but mine has never gone past lukewarm, even running for 6-8 hours at a time. I left the top off my PID so I could monitor everything a little easier and put the top back on after the second session and quit worrying about it. I do have mine on a heatsink in an area with good ventilation. You probably noticed that mine is made from a computer power supply box. I removed all its innards and found there was plenty of room to build a PID inside, and it was free! |

|

|

|

|

If you were my friend, I'd really like you.

|

|

|

|

|

One other little thing. Things like switches, plug-ins, cords, wire, switches, indicator lights, fuse holders, and outlets were all readily available at my local Ace Hardware store. Being the anal type, I also color coded all my circuits using wire with different insulation colors. Ace had six or eight different colors of 10 gauge wire. You'll find wire gauge can be a source of discussion on some sites, but I chose 10 gauge. 12 might also work, but since I'm controlling a heating device, I went a little heavier. I wouldn't consider 14 gauge or smaller under any circumstances myself. I saw one guy build one similar to mine that salvaged 18 gauge wire from the power box for some circuits. I only used one foot each of six different wire colors, new wire cost me something like 12 bucks. My case is metal, but I ran auxiliary grounds for everything anyway. There were plenty of open connectors on the Buss bar that made this easy to do.

|

|

|

|

|

Nickname: Doc. Came with wild hair and a DeLorean

|

I use a very similar setup for the old toaster oven I use for Cerakoting/powder coating, and I also use it to power/control my heat treating oven and smoker. Super useful and versatile. If you want optimally accurate control, be sure to run the autotune sequence at the temperature you want to run steady-state. Vents in the casing should be enough to keep the heatsink in check.

|

|

"We're all new here, kid. The old ones are either dead or in the hospital. What the hell did you expect, a two week pass to Paris? Get in line and do what you're told, or you'll be dead before sunup."

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.