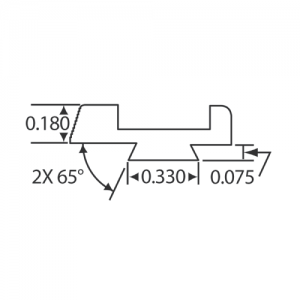

Using this sight just a reference (which needs a .075 deep dove tail channel, after you have created the top flat to lock it in first) since you sight may need to deeper or shallower cut,

" />

As for the sight you plan on using, see if it has a spec sheet to pull measurements, or measure it for the needed spec cut: since dove tail spec for differnet dove tail sights are all over the map (some are side angled 60*, while some are 65* instead, and as for depth of dove tail channel cut, measure the sight twice to see what is needs).

Next, What is going to be the wall thickness from the bottom of the dove tail channel to the bore, and what caliber ?

As for shallower dove tail cut with a sight that should have a deeper dove tail instead, kind of looks like ass instead.

So instead of ending up with the bottoming flat on the sight way above the barrel top surface, will just mill the bottom of the front sight dove tail shorter so the sight's bottoming flat to mate's top of the barrel correctly to lock the Dove tail sight in place in a shallower dove tail slot, then just grind the bottom off a HSS dove tail cutter so it will cut the needed shallower dove tail to use it one time instead. Here, end mill to make the needed center of channel cut first, then dove tail cutter in to remove the V metal on each side afterwards. Also, the width of the dove tail site can be narrowed so it not hanging past the dove tail in the barrel a country mile both sides as well.

Or, just use a dove tail insert to bolt it to the barreli f it does not have enough wall thickness to begin with ,and install the dove tail sight into it instead.

http://www.midwayusa.com/front-sight-ramps/br?cid=15956

http://www.midwayusa.com/front-sight-ramps/br?cid=15956

Side note on the lever action gun with the front sight that looks like ass with the bottom flat of the sight way above the barrel, this would have been a better option instead.

If you need a front sight that is higher, then something like this instead.

Win a FREE Membership!

Win a FREE Membership!