|

Posted: 12/1/2022 4:39:29 PM EDT

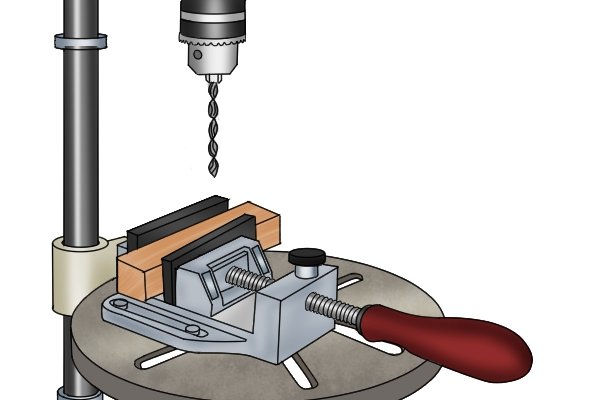

I got this one

Failed To Load Product Data Has slots for bolts, the drill press table has slots for bolts, but I played with aligning it and it seems like those are no help because the work piece wouldn't be aligned with the center when I center it the slots aren't aligned. Clamps? Offset the table? Haven't played with that last idea but it just occurred to me. |

|

|

|

Spin it till it aligns. Or twist the table to the side, or spin the table...

|

|

|

|

You sometimes have to get creative, like settling for one bolt when you planned on two.

Using one bolt and a clamp of some kind. Lots of moving and adjusting, will get you there. ETA Buy a X Y Vise is another option. |

|

|

|

Quoted: You sometimes have to get creative, like settling for one bolt when you planned on two. Using one bolt and a clamp of some kind. Lots of moving and adjusting, will get you there. View Quote Cool, thanks that points me in the right direction. I probably would've figured it out but I wanted to save time by asking here

|

|

|

|

Haven't had a ton of luck with this either. Definitely not an exact science.

|

|

|

|

your hand....and hope to god the bit doesn't catch whatever you're drilling and rip it out of your hands

|

|

|

|

You don't. I always leave it free floating on the table. It's not like you have x and y travel so you would have to unbolt it and rebolt it every time.

|

|

|

|

Quoted: Cool, thanks that points me in the right direction. I probably would've figured it out but I wanted to save time by asking here  View Quote View All Quotes View All Quotes Quoted: Quoted: You sometimes have to get creative, like settling for one bolt when you planned on two. Using one bolt and a clamp of some kind. Lots of moving and adjusting, will get you there. Cool, thanks that points me in the right direction. I probably would've figured it out but I wanted to save time by asking here  Be careful your work piece and vise does not move if inadequately clamped. Not likely, but with a big enough bit, or hard to drill item it could happen. Another idea, use a bolt on the vise, and clamp a stop of some type, like a block of wood, to keep the vise from moving. |

|

|

|

Don't bother.

Find a piece of tube/pipe you can put over that handle and rest against the column of your drill press to counter the torque and let the vise float. If you've got a drill press table with T-slots, you can get an appropriately sized hold down clamp set for the odd cases where rigid fixturing is called for. |

|

|

|

Quoted: You don't. I always leave it free floating on the table. It's not like you have x and y travel so you would have to unbolt it and rebolt it every time. View Quote So this! Never bolt the vise to a drill press. Hold the vise with your left hand, feed the bit with your right. When something goes horribly wrong, and it will, let go of everything and switch the press off. |

|

|

|

Quoted: Has slots for bolts, the drill press table has slots for bolts, but I played with aligning it and it seems like those are no help because the work piece wouldn't be aligned with the center when I center it the slots aren't aligned. Clamps? Offset the table? Haven't played with that last idea but it just occurred to me. View Quote It depends on the work you do and what you are drilling. Technically, the vise doesn't have to be mounted to the table. You can secure the workpiece in the vise and move the vise around on the table if you want to. There is also no rule that says the workpiece needs to be centered in any way. I've drilled at times with the entire vise to the left of the spindle. |

|

|

|

I like to mount it so the slots in your vice perpendicular to the slots your table. Mount with atleast two bolts or a t-nut/stud kit that fits the slots in your press table like this one....

Mounting T-Nut Kit  |

|

|

|

|

|

Mount the vise to this

|

|

|

|

Gorilla Glue and in its absence, saliva.

Apply the latter with your finger and don't lick the bottom of the vise or the drill press table. Apply the latter with your finger and don't lick the bottom of the vise or the drill press table.

|

|

|

|

STEP CLAMPS will allow you to position the vice how you need it on the table. Can also be used to hold something larger than your vice directly on the table.

|

|

|

|

One more thing, I tend to only clamp in cases where I need to change bits and keep the piece aligned, when I'm using something that will want to chatter, or a bit large enough it will want to spin the work piece. If the problem is it wanting to spin, c clamps might not always be enough. It's a good idea to position the work and your body so that if it does spin free it won't hit you.

|

|

|

|

Quoted: I got this one www.amazon.com/dp/B077XN118X Has slots for bolts, the drill press table has slots for bolts, but I played with aligning it and it seems like those are no help because the work piece wouldn't be aligned with the center when I center it the slots aren't aligned. Clamps? Offset the table? Haven't played with that last idea but it just occurred to me. View Quote whats the table look like? |

|

|

|

|

|

Hold it down with clamps, that way you can easily adjust it's location after you secure something in the vise.

|

|

|

|

if your drill press has T-slots t-nut, bolt and washer. if no T-slot use a big c clamp. if that doesn't work turn your vice so the handle hits the back column so your vice handle pushes into the column in relation to rotation

|

|

|

|

That’s what kids are for.

No, I use the clamps goatrider recommended. |

|

|

|

|

|

|

|

|

|

|

|

Quoted: Mount the vise to thishttps://www.ar15.com/media/mediaFiles/493363/6E8BEECC-81F5-4391-869E-81736C3FE1BE_jpe-2620310.JPG View Quote This and step clamps are most versatile setup in my opinion. |

|

|

Failed To Load Product Data |

|

|

|

|

|

Mine is set up just to chamfer holes. When I did need a vise I use these clamps in the T slots.

|

|

|

|

|

|

|

|

Quoted: Mount the vise to thishttps://www.ar15.com/media/mediaFiles/493363/6E8BEECC-81F5-4391-869E-81736C3FE1BE_jpe-2620310.JPG View Quote That's what I did. Bought a similar one and vice from ENCO way back in the day. Cheap Chinese stuff. I unboxed them and totally reworked the ways and screws, support bearings. Has served me well for about 15 years now. |

|

|

|

Nuts, bolts...

...perhaps some square washers or strut brackets (as washers) |

|

|

|

You need a 3/4"

|

|

|

|

Quoted: Get one of theses. Linky https://www.ar15.com/media/mediaFiles/483218/download__8__jpeg-2620403.JPG View Quote I have that set. Great for 80% lowers. |

|

|

|

Quoted: like so: https://images.homedepot-static.com/productImages/1b7c92c1-c128-4c47-bfd1-36c135eaab47/svn/wen-drill-presses-4214-40_1000.jpg View Quote View All Quotes View All Quotes Quoted: Quoted: whats the table look like? like so: https://images.homedepot-static.com/productImages/1b7c92c1-c128-4c47-bfd1-36c135eaab47/svn/wen-drill-presses-4214-40_1000.jpg Stop trying to square the vise up with the table. Turn it 45 degrees. |

|

|

Failed To Load Product Data Or if you have the budget  Failed To Load Product Data |

|

|

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.