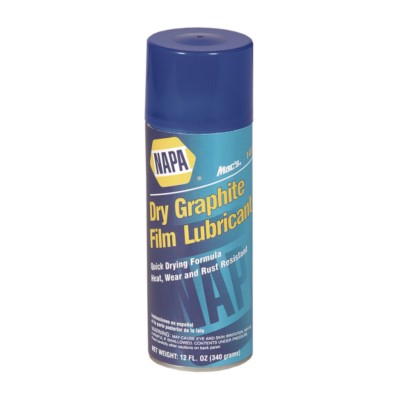

Just a 2 inch or 3 inch long ramp coated with graphite spray:

If your ramp is steel, you're gonna want to polish it to almost a mirror finish. Then while it is still cool spray on a coat of the graphite spray pictured above. Let that dry. Spray on a second coat.

Somehow you are going to have keep the ramp hot...either with some other heating element or attached to your lead smelting pot.

I used an ammo can of water...yes plain ol' tap water (none of this B.S. of fabric softener, brake fluid, diesel fuel, or antifreeze).

The bottom edge of the ramp was about a quarter inch from the top of the water.

Water seeks its own level.

So the ammo can was put into position under the ramp and then water was added til water starts flowing over the brim. Then I level the ammo can to the water. Then as the lead shot displaced the water, I would just let the water drip to the floor and make its way to a drain.

With just one orifice dripping lead, it is going to be a while.

You may need something to vibrate or tap against the pot to get the lead to drip faster.

Let us know how those 3D printer tips work and how tapping your pot for those threads goes.

Win a FREE Membership!

Win a FREE Membership!