|

Posted: 9/6/2016 9:09:30 PM EDT

[Last Edit: ReefRaider]

So as to not take another thread here off topic. Thought I'd start a new one.

Looking at maybe doing some up grades to my S1050s. Was wanting some input as to what some of you might have tried and liked . Also what didn't work out for you. About 3 years ago some one gave me a bearing for the shell plate . I never put it on though. Now I'm reading that the bearings can make the shell plate retainer hit the tool head when it's all the way at the bottom of the down stroke. Even if you haven't done any up grades to your 1050. I also would like to know how you have your tool head set up to process 5.56 brass. I've always use all Dillon dies with the exception of the last station. Which has a redding neck sizing die with expander. It helps to roll any burr left by the trimmer and gives very consistent neck tension. ETA Keep in mind I run my 1050s on a PW auto drive. The up date's done as of now. Level 10 delrin guide rods and also their delrin primer slide sleeve cover. Fast and Friendly Brass , super duty small swager rod. If you do a lot of large swaging they have a large rod too. Home made case feeder plunger , to slow the .223 case feeding in to the shell plate. NOTEif your doing a caliber conversation to .233 on the 1050. Fast and Friendly Brass sells a up graded #3 shell that from what I'm told is well worth the money over the Dillon one. They also sell other shell plates for other caliber conversation s. Check their web site. They are also a sponsor of ARFCOM ! |

|

|

|

|

The PW drive is just a motor, with a manual clutch that you have to adjust correctly.

Hence the write up I did to add in the needed features so if you run into problems, it will not kill the machine. Bluntly, if you bought one when they first came out, it and the needed devices was under $1K in the end. What the Mark 7 did, was added in the needed futures, along with a VLD controller that has amperage sensing as well. Simply, this made there system turn key instead, but at the tune of around $3k in the end with all the sensors isntead. Lets face it, for just a couple of calibers on a 1050, your getting into the $3k range, and when you add another $3k on top of that, then you into the inline reloaders that is a better option than a 1050 instead. I bring this up, since if anyone has ever seen a well used 1050 that a ammo shop is selling to pick up a new one, the reason is its just cheaper to buy a whole new machine, then to try to rebuild a worn out 1050 instead. Granted that the 1050 does have a lot of ball bearings, but the down side to the machine is no replaceable sleeve between the base and the ram for a machine. Then you get into the issue that the primer tube will only hold so many primers, and does not allow for reloading the tube when the machine is running as well. |

|

|

Posted By PlaymoreMinds:

'Twas not the <cough> sweet and innocent <cough> PlaymoreMinds... <---skips away in frilly skirts to Candyland, leaving gutters and snorkels FAR behind. |

|

Great thread!

|

|

|

|

|

Wonder how many primers the new Mark 7 reloading press will handle....

Originally Posted By Dano523:

The PW drive is just a motor, with a manual clutch that you have to adjust correctly. Hence the write up I did to add in the needed features so if you run into problems, it will not kill the machine. Bluntly, if you bought one when they first came out, it and the needed devices was under $1K in the end. What the Mark 7 did, was added in the needed futures, along with a VLD controller that has amperage sensing as well. Simply, this made there system turn key instead, but at the tune of around $3k in the end with all the sensors isntead. Lets face it, for just a couple of calibers on a 1050, your getting into the $3k range, and when you add another $3k on top of that, then you into the inline reloaders that is a better option than a 1050 instead. I bring this up, since if anyone has ever seen a well used 1050 that a ammo shop is selling to pick up a new one, the reason is its just cheaper to buy a whole new machine, then to try to rebuild a worn out 1050 instead. Granted that the 1050 does have a lot of ball bearings, but the down side to the machine is no replaceable sleeve between the base and the ram for a machine. Then you get into the issue that the primer tube will only hold so many primers, and does not allow for reloading the tube when the machine is running as well. View Quote |

|

|

|

|

Originally Posted By blake-b:

I've got two S1050s. I'm lazy and don't want to move things around too much. One is dedicated to 223/556 and the other 308. Both of them are set up the same way. I have a total of 4 tool heads. One for each caliber to process brass and one for each caliber to load. It doesn't take too long to switch out a toolhead. I don't have to mess with the different systems that rely on primer size, caliber specific feeding parts, etc. They are set up the same way. I use a mix of Dillon, Lee, and Lyman dies. Processing head: Station 1 is a Lee universal decapper. Station 2 swages Station 3: Empty (no primers loaded) Station 4: Empty (where powder measure would be) Station 5 is where an electric trimmer is (RT1200 for 223; Bosch 1617EVS router with an adapter kit for 308. I went with the router just to try it. Both the router setup and a Dillon trimmer came out similar price wise so I thought I'd try it) Station 6 empty Station 7 is a Lyman M die to open the necks up just a little View Quote How much are you opening up the neck with the M die? I'm using a Mr. Bullet Feeder, and thought I read to open the neck to .224, but now am being told that is to large to tension properly for an autoloader, but any smaller and bullets topple (MBF) when advancing the shellplate... |

|

|

---

NRA Life Member USN Retired |

|

Originally Posted By 78Staff:

How much are you opening up the neck with the M die? I'm using a Mr. Bullet Feeder, and thought I read to open the neck to .224, but now am being told that is to large to tension properly for an autoloader, but any smaller and bullets topple (MBF) when advancing the shellplate... View Quote I just set Mine until the bullet just sits on the case. I dunno if there is a way to measure it, just an eyeball thing. |

|

|

I just gotta ask........

|

|

I just gotta ask........

|

|

my MBF 223 conversion didn't include a powder/expander - I though they were only for pistol calibers...

I did notice the Dillon Swage backup rod opens the case back up similar to what an M die does for 223, so am going to experiment a bit with the two. I have an PW Autodrive on the way though so holding off on any 223 work for a few days. |

|

|

---

NRA Life Member USN Retired |

|

Originally Posted By 78Staff:

my MBF 223 conversion didn't include a powder/expander - I though they were only for pistol calibers... I did notice the Dillon Swage backup rod opens the case back up similar to what an M die does for 223, so am going to experiment a bit with the two. I have an PW Autodrive on the way though so holding off on any 223 work for a few days. View Quote Sorry if I missed it but what kind of bullet will you be loading? The swage rod may be enough for BT bullets but not FB bullets like Hornady 55gr SP. |

|

|

|

|

---

NRA Life Member USN Retired |

|

|

|

Originally Posted By djryan13:

Probably be ok. If they topple, get a m die. I run mostly SP so its required. View Quote Yeah I load my SP loads on a Coax ;). This is for range blaster ammo, in bulk - have the M die so will just open up till the won't topple - which is really where I started, but some were saying that's too little neck tension so figured I would double check... Thanks all :). |

|

|

---

NRA Life Member USN Retired |

|

Hey,

Has anybody used any 1050 parts from fast and friendly brass? They spend a good chunk of the text on their website talking trash about Dillon's parts and the material they are made of. I can tell you guys for a fact he is flat out lying about the 1050 "link arm" and "crank arm" being made out of a low grade aluminum casting. The factory stock link arm is made out of 6061 t-6 barstock and CNC machined. He has made new parts out of the exact same material as the Dillon spec, to guessed tolerances, and without the hard anodizing. He also is charging more for the same part from Dillon. There were also prototypes made out of 7075 but they were too brittle. Edit:extra clarification |

|

|

|

|

Originally Posted By NoScoE30:

Hey, Has anybody used any 1050 parts from fast and friendly brass? They spend a good chunk of the text on their website talking trash about Dillon's parts and the material they are made of. I can tell you guys for a fact he is flat out lying about the 1050 "link arm" and "crank arm" being made out of a low grade aluminum casting. The link arm is made out of 6061 t-6 barstock and CNC machined. He has made new parts out of the exact same material as the Dillon spec, to guessed tolerances, and without the hard anodizing. He also is charging more for the same part from Dillon. There were also prototypes made out of 7075 but they were too brittle. View Quote I bought a few parts including swage rods. No idea if its snake oil or not but I like em. They are a site member I think so they sell stuff in EE. Havent seen anyone complain about the stuff here. Nothing wrong with competition... |

|

|

|

|

|

|

I use the de-capping pins, swage rods and shell plates, they seem to be nice stuff.

I hear You on the Trash talk, I could do without that part. Just don't start anything in this thread. Some of Us got a lot of time and effort in it. I'd rather not see it get locked. |

|

|

I just gotta ask........

|

|

I've gone though 2 Dillon small swagers. They are soft. Now have the F&FB swager installed in one of the 1050's. It seems to be holding up. In fact it was removed yesterday while cleaning and lubing the press for another run. One thing about it, wish it had a hex on it for adjusting instead of just two flats. It won't be long before another one gets ordered.

Over all I think he makes some good products for the 1050. Not that I have a need for them all, at least not yet. Dillon really should pay attention to what he's saying. They could learn a thing or two. |

|

|

"There is a fine line between having balls and being a dumb ass" GB

"Machine Gunners - Accuracy By Volume" |

|

Originally Posted By ReefRaider:

I've gone though 2 Dillon small swagers. They are soft. Now have the F&FB swager installed in one of the 1050's. It seems to be holding up. In fact it was removed yesterday while cleaning and lubing the press for another run. One thing about it, wish it had a hex on it for adjusting instead of just two flats. It won't be long before another one gets ordered. Over all I think he makes some good products for the 1050. Not that I have a need for them all, at least not yet. Dillon really should pay attention to what he's saying. They could learn a thing or two. View Quote +1 on hex. Its a PITA to remove/adjust/tighten with Mark 7 installed. |

|

|

|

|

Originally Posted By FastAndFriendlyBrass:

We can back up our claims. Can you back up yours? http://fastandfriendlybrass.com/images/Destructive_Test.JPG View Quote Nice! Now where are we on making the the swaging rod a hex adjustment? |

|

|

|

|

As for the swage rod... We'll get those changed to hex from a single flat on the next order. We did the single flat as we thought it would be easier to tell if it had moved after being set due to a poorly tightened jam nut.

|

|

|

|

|

Originally Posted By FastAndFriendlyBrass:

As for the swage rod... We'll get those changed to hex from a single flat on the next order. We did the single flat as we thought it would be easier to tell if it had moved after being set due to a poorly tightened jam nut. View Quote Thanks... I was considering buying the Mark 7 swag sensor but the fact I just bought your rods stopped me. Their sensor requires a special rod I think. Sigh... |

|

|

|

|

Originally Posted By FastAndFriendlyBrass:

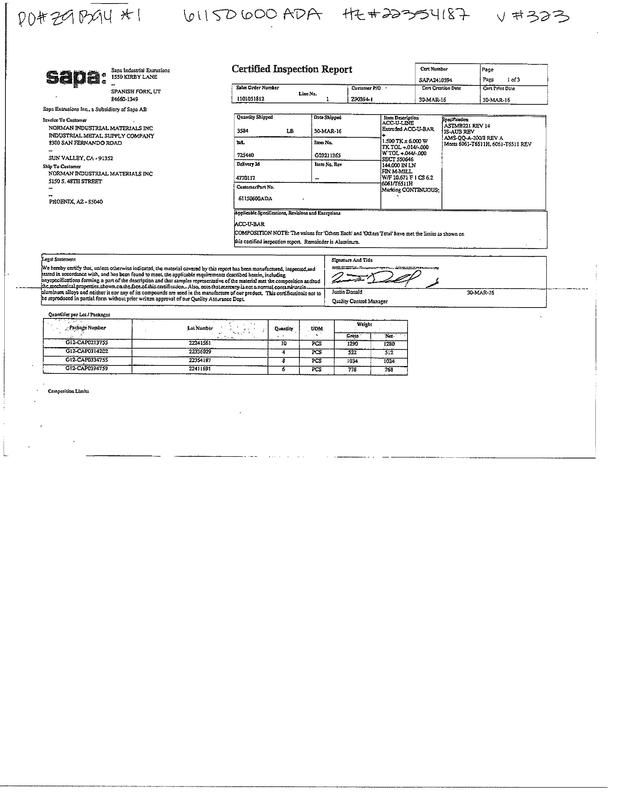

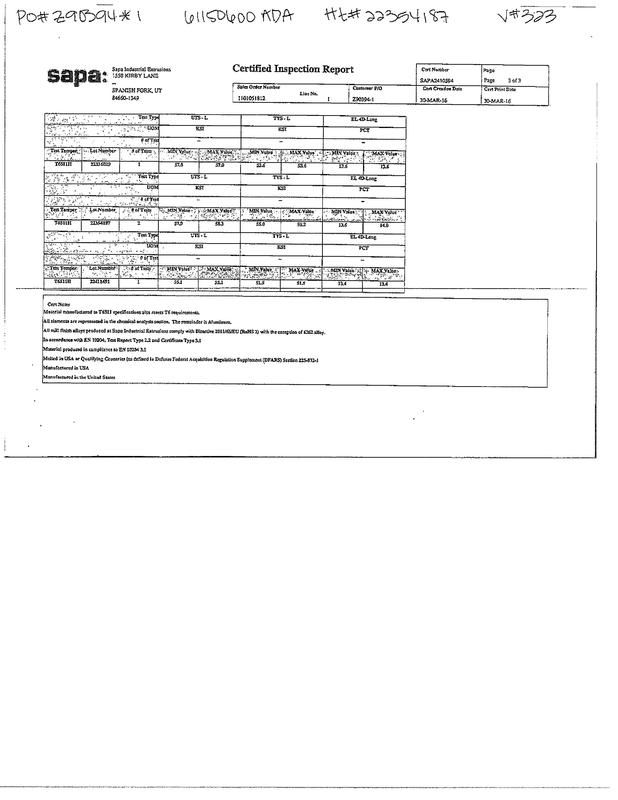

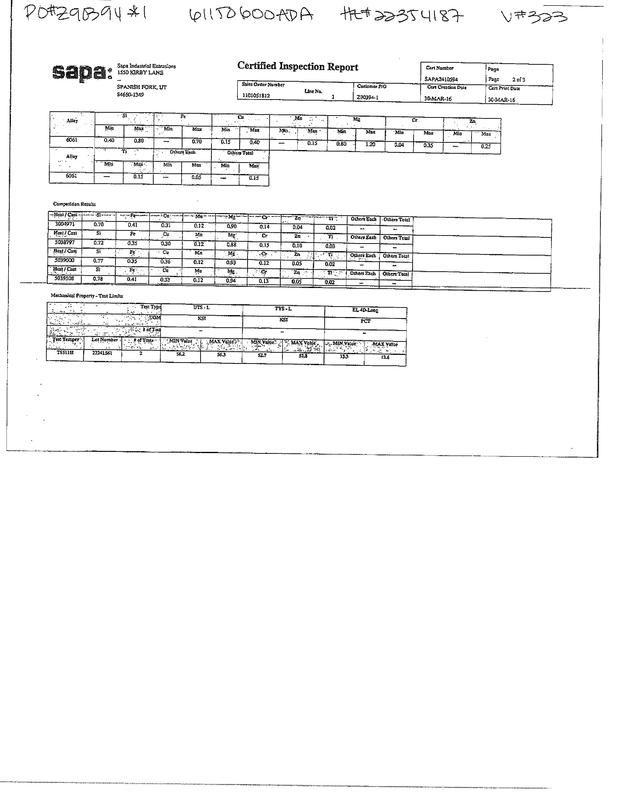

We can back up our claims. Can you back up yours? http://fastandfriendlybrass.com/images/Destructive_Test.JPG View Quote Let me start off by saying I am NOT a Dillon employee. Calling you a liar was a little harsh. I apologize for that. Misinformed is a better word. I don't know what happened at the lab you paid, but they messed up. You might want to consider getting your money back. I make the part in question for Dillon. (and quite a few others) The Dillon Super 1050 link arm starts as a 12' bar of 1.5" x 6" rectangle 6061-T6511 barstock. It is CNC machined on a Makino A51NX horizontal. It is finished with a hard black anodize. Here are the material certs for the latest batch of material we ordered for this job. We purchased approx 1500 pounds. Is this is the proof you are looking for?

|

|

|

|

|

Thank god my original link arm still works. I wouldnt want to have to:

a. decide between the two b. pay that much for one... dang.. What are these items rated to? I have at least 30k rounds loaded or brass processed in almost 3 yrs now.. |

|

|

|

|

Global Warming Hoax Skeptic before it was cool

|

I am watching this thread closely.

Lets have a polite discussion with no more name calling. dryflash3 |

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

|

Originally Posted By NoScoE30:

Let me start off by saying I am NOT a Dillon employee. Calling you a liar was a little harsh. I apologize for that. Misinformed is a better word. I don't know what happened at the lab you paid, but they messed up. You might want to consider getting your money back. I make the part in question for Dillon. (and quite a few others) The Dillon Super 1050 link arm starts as a 12' bar of 1.5" x 6" rectangle 6061-T6511 barstock. It is CNC machined on a Makino A51NX horizontal. It is finished with a hard black anodize. Here are the material certs for the latest batch of material we ordered for this job. We purchased approx 1500 pounds. Is this is the proof you are looking for? http://i18.photobucket.com/albums/b126/Mr_Deagle993/20170223165656588-page-002_zpsoricx9k1.jpg http://i18.photobucket.com/albums/b126/Mr_Deagle993/20170223165656588-page-004_zpsmjcdil5c.jpg http://i18.photobucket.com/albums/b126/Mr_Deagle993/20170223165656588-page-003_zpswhhdmuhu.jpg View Quote So I post up an actual specific destructive analysis, and your rebuttal is a generic, unreadable material certification that comes with every shipment of metal? You calling me a liar is pretty much straight up libel. Tread lightly. |

|

|

|

|

NoScoE30 and FF&B,

I see that You guy's are having an issue here. Would you please take it to PM's and leave this thread alone? I know You guy's don't care if it gets locked, but a lot of Us do. |

|

|

I just gotta ask........

|

|

Thanks Dave.

Is anyone running 357 sig on the 1050? Only way I could get neck tension right is to skip the 9mm swaging rod in swaging station. I would still like the brass held while swaging (mixed "once fired" brass). Thinking about using 223 rod. Anything better out there? I am still able to expand slightly with MBF powder insert and so far, tension seems good. |

|

|

|

|

Global Warming Hoax Skeptic before it was cool

|

Originally Posted By FastAndFriendlyBrass:

So I post up an actual specific destructive analysis, and your rebuttal is a generic, unreadable material certification that comes with every shipment of metal? You calling me a liar is pretty much straight up libel. Tread lightly. View Quote |

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

|

I was going to tell them that, but knew you wouldn't be long in getting here.

|

|

|

"There is a fine line between having balls and being a dumb ass" GB

"Machine Gunners - Accuracy By Volume" |

|

If it's not a discussion of the Dillon take it somewhere else or I'll remove you.

|

|

|

|

|

Global Warming Hoax Skeptic before it was cool

|

Please continue with this thread, the poster with the issue won't be back.

|

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

|

As I was saying....

Originally Posted By djryan13:

Is anyone running 357 sig on the 1050? Only way I could get neck tension right is to skip the 9mm swaging rod in swaging station. I would still like the brass held while swaging (mixed "once fired" brass). Thinking about using 223 rod. Anything better out there? I am still able to expand slightly with MBF powder insert and so far, tension seems good. View Quote |

|

|

|

|

Originally Posted By dryflash3:

Take this somewhere else, you have both had your say. dryflash3 View Quote Where should they take this discussion? I am interested in outcome. I can understand not cluttering up this thread but can either one of them start a new thread? I personally have 4 1050s. I find that as soon as I encounter unknown resistance I stop and don't force anything. I rarely break parts. I do find that the cleaner and better lived I creep them they run smoother. Fortunalty Dillon is local so if I do parts are only a quick drive away. Don't want to get this thread locked but I am interested in where these two parties can politely discuss this |

|

|

|

|

Global Warming Hoax Skeptic before it was cool

|

To a non technical forum.

|

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

|

I just gotta ask........

|

|

|

|

but You'll always need a .357 Sig swage rod.

It's only money..................

|

|

|

I just gotta ask........

|

|

Originally Posted By ChevelleDave:

but You'll always need a .357 Sig swage rod. It's only money..................  View Quote True... speaking of money... I would love something like this: http://www.markvii-loading.com/Mark-7-Offloading-System_p_35.html but cant see paying 100 for it. Anyone have any ideas how to build something like that? |

|

|

|

|

Originally Posted By djryan13:

True... speaking of money... I would love something like this: http://www.markvii-loading.com/Mark-7-Offloading-System_p_35.html but cant see paying 100 for it. Anyone have any ideas how to build something like that? View Quote That is nice. Looks like a automotive intake hose hooked up an air duct. I like that idea. car air duct |

|

|

PSALMS 144-1 Blessed be the Lord my strength, which teacheth my hands to warre, and my fingers to fight:

|

|

Originally Posted By prskiller:

That is nice. Looks like a automotive intake hose hooked up an air duct. I like that idea. car air duct View Quote great idea!!! |

|

|

|

|

Originally Posted By djryan13:

Originally Posted By prskiller:

That is nice. Looks like a automotive intake hose hooked up an air duct. I like that idea. car air duct great idea!!! That's all fine and dandy, but the Mark Seven product uses a much higher quality plastic as their raw material.

|

|

|

I just gotta ask........

|

|

PSALMS 144-1 Blessed be the Lord my strength, which teacheth my hands to warre, and my fingers to fight:

|

|

Global Warming Hoax Skeptic before it was cool

|

Originally Posted By prskiller:

You may be right as it looks to be a intake duct off a Ferrari View Quote View All Quotes View All Quotes Originally Posted By prskiller:

Originally Posted By ChevelleDave:

That's all fine and dandy, but the Mark Seven product uses a much higher quality plastic as their raw material.  You may be right as it looks to be a intake duct off a Ferrari If you don't have an extra Ferrari duct laying around, how about an oil bottle with the bottom cut off? Or maybe a similar style bottle with a larger mouth? |

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

|

Some of you might remember the thread Flamethrower did years ago. He had a similar set up and was running some .40 I believe. Long story short. He had one detonate as it hit the bottom. The case was all over the place and the projectile was in the ceiling.

|

|

|

"There is a fine line between having balls and being a dumb ass" GB

"Machine Gunners - Accuracy By Volume" |

|

For My volume of loading I like to load a tube of primers, and box up a 100 at a time and QC them.

I'll have to post up my case arranging set up. Still ironing out the bugs, but in short, I use the case feeder to drop the cases so they are all oriented the same way. I use a piece of tube to divert them onto a plywood shelf,then I can scoop them up a handful at a time. I cannot sit there and pick the cases one at a time and orient them base up. This way It is a lot easier for me to inspect, sort and load them into the annealor. I need to get some other stuff done and out of the way first, but I will need to get back on it as I'll have a far amount of third fired blasting ammo that will need a trip through the annealor soon |

|

|

I just gotta ask........

|

|

Originally Posted By ReefRaider:

Some of you might remember the thread Flamethrower did years ago. He had a similar set up and was running some .40 I believe. Long story short. He had one detonate as it hit the bottom. The case was all over the place and the projectile was in the ceiling. View Quote Sounds like a good time! I think I'll stick with the blue bin.

|

|

|

I just gotta ask........

|

|

Originally Posted By ReefRaider:

Some of you might remember the thread Flamethrower did years ago. He had a similar set up and was running some .40 I believe. Long story short. He had one detonate as it hit the bottom. The case was all over the place and the projectile was in the ceiling. View Quote Well that's not good. Guess I'll stick to the blue bin. |

|

|

PSALMS 144-1 Blessed be the Lord my strength, which teacheth my hands to warre, and my fingers to fight:

|

|

"There is a fine line between having balls and being a dumb ass" GB

"Machine Gunners - Accuracy By Volume" |

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.