Some details on Pawl adjustments, sounds like it may just need a finer adjustment.

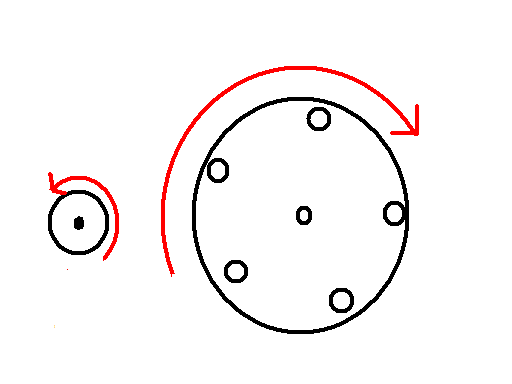

First picture:

What it shows is if you rotate the pawl screw LEFT (counterclockwise), the shell plate will rotate more RIGHT (clockwise).

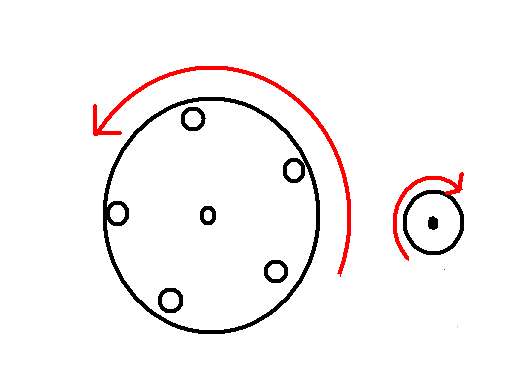

Next picture:

What it shows is if you rotate the pawl screw RIGHT (clockwise), the shell plate will rotate more LEFT (counterclockwise).

Rule 1:

Left pawl adjusts the shell plate when it comes down. This is the one that causes problems with cases feeding into the shell plate or priming problems (they both rely on the the downstroke of the shell plate).

Rule 2:

Right pawl adjusts the shell plate when it goes up. This is the area that causes problems with cases entering the dies (jamming on the sizing die is the big problem child).

The rest:

Now, another key point to keep in mind about the clicks.. The manual says to listen for clicks as the shell plate is locked into place at the end of the press arm stroke. They don't explain it very well though. When I was first fighting the left pawl (shell plate problems with priming and case feeding), the manual said to listen for 2 clicks. They didn't explain that the clicks are VERY soft and I was mistaking the releasing of the RIGHT pawl being the first click when in reality, the proper click is a very soft one. The clicks are first the sound of the pawl releasing and the second click is the sound of the 2 ball bearings locking the shell plate into proper place.

The key about that is you want the adjust the pawls so that the 2 distinct clicks merge into one click, that means the pawl is releasing exactly at the same time as the ball bearings are locking into place. If you are thinking that the loud clicking is the proper noise, then you are wrong like I was.

And when adjusting these pawls, you need to move the press arm VERY slowly.

Win a FREE Membership!

Win a FREE Membership!