Short of just a worn out mag spring that is causing the problem,

Let break it down,

1. make sure that the threaded end of the mag catch button is flush with the face of the mag release catch. If it not, then push the mag release button all the way in with a pencil eraser, and spin the catch on the other side of the receiver the needed amounts so end of the threaded section is flush with the face of the button. If you find that you end up either a half thread in, or half thread out of the tip of the threaded section flush with the face of the mag release button, then spin the catch all the way out, turn the mag release button 180*, then reinstall the mag release.

2. with the upper shotgunned open, work the bolt catch to make sure it not bind in the slot for it in the upper receiver. If you feel that the bolt catch is binding, then add some CLP and work the catch by hand until the bolt catch loosen up.

3. Since you now know how to remove the mag catch, do so, and with the mag bodies only, one by one insert the mag into the well tight up against the bottom of the carrier against a locked home bolt, and take a look at the catch slot in the mag, and how it compares to the bottom of the mag catch slot in the lower receiver. The bottom edge in the mags catch slot, should be just a slight bit higher than the bottom of the bottom ledge in the receiver slot, and not way up higher instead (read too much of a gap from the top of mag lips, to bottom of the carrier when they are locked in place.

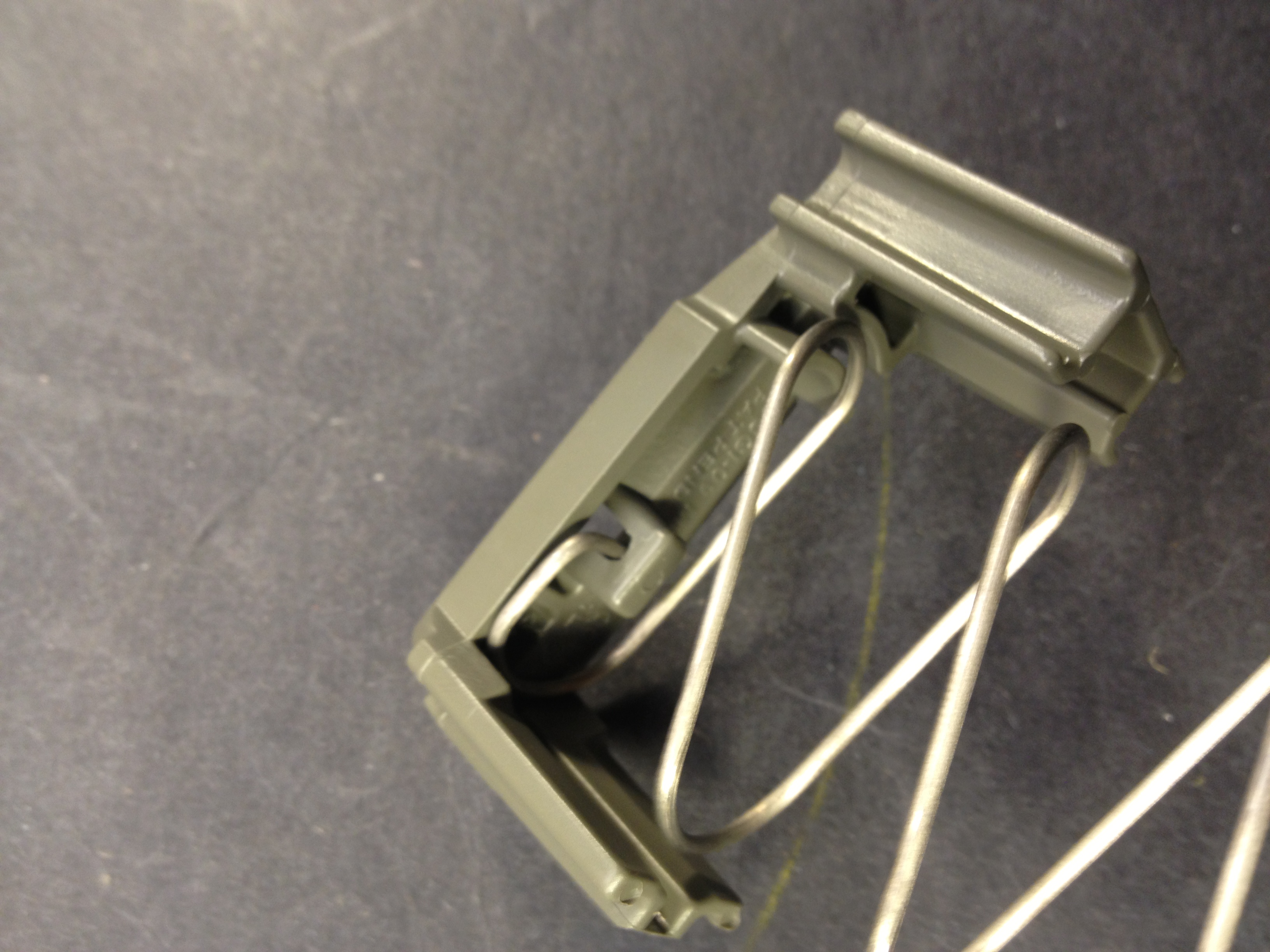

Now since we already have the mag stripped down to the bodies, lets check the mags out.

Starting with the mag spring installed on the follower, the long loop on the top of the spring should be forward, towards the forward of the follower.

With the spring correctly installed on the follower, and the parts all CLP cleaned, put a mag back together.

Now add only two rounds to the mag, shove the front of top round down, let the two rounds snap back up, then shove the top round via the back rim side down into the mag, and let the two rounds snap back up. In either side push down test with the rounds free to snap back up in the mag, the top round should have popped back up, with the entire lenght of the top round tight against the bottom of the feed lip. Now add in a third round and do the test again, and pay close attention to which side you are pushing down on, is not allow the 2 or three rounds to snap back up with the top round tight against the entire bottom surface of the mag lip.

Tweaking mag spring to get the top round in the stack to come up tight against the entire feed lip on recovery.

On the spring coil loop just off the front of the follower, we are going to bend that loop either wire farther apart, or closer together, to equal out the spring pressure against the follower, so the spring is putting even pressure against the follower to remove the top round evenly to the bottom of the feed lip. If its the front of the follower that needs more spring tension, the first coil will need too be bent more apart, and if it the back of the follower that needs more pressure, then that first coil wind that drops off the follower bottom will be bend closer together instead. So with the spring off the follower, grab both sides of the wire right after the coil bend, and bend/tweak that first coil drop loop in the needed direction.

Once you have the mags recovering correctly, now install the empty mag in the rifle, pull all the way back on the charging handle, and confirm that the mag catch is rising up in front of the bolt face, to stop the bolt via the face of the bolt (not just catching the bottom of the carrier instead. If the bolt will not retract that far back, or during the last inch of charging handle pull, the tension to pull the charging handle back increases, then you have a problem with something now right in the rifle instead. It could be the wrong spring in play that is coil binding up, too long of a butt stock screw (a2 screw being used with an A1 stock), or the receiver extension not milled deep enough for the buffer, or wrong lenght buffer in play. Also during live fires, make sure that when the bolt catch is catching the bolt on the bolt face, and not just on the bottom of the carrier with the 30 round mags.

If the bolt face is coming back far enough for the catch to rise up, but the 20 round mags will still good springs is not lifting the non-binding in slot catch up, then chances are when you install the bolt catch, you did not clean out the debris in the mag catch spring channel/it was not drilled deep enough, and the bolt catch return spring it creating too much tension for the mag follower to over come.

Note, you install the spring into the channel, then the buffer on top, then the catch against two. Do not install the spring buffer towards the receiver, under the spring.

If the bolt catch spring channels is clean of any debries, but was milled too shallow,

https://www.ar15.com/forums/t_3_66/648701_-ARCHIVED-THREAD----AR-15-Bolt-Catch-Plunger-is-stuck.html&page=1

Win a FREE Membership!

Win a FREE Membership!