Here is a pic of my breakfast. It really isn't a good pic either. It was more of an afterthought. It is just a bowl of grits and some black coffee. This breakfast made me reflect on what I am thankful for today.

Growing up all of my family had a trade, and all of their friends did as well. I grew up around mechanics. machinists, and welders. From the time I was old enough to walk I was around a shop helping and watching. Over my childhood I picked up on lots of skills that most folks will never get to enjoy. Most of the folks I hung around growing up did things that just aren't done these days. I grew up silver soldering, brazing with clothes hangers, rebuilding and repairing old single cylinder hit and miss engines, etc. I was driving a tractor before most kids were riding a bike on their own. I learned to weld, run a milling machine, and run a lathe at a young age. I am thankful that I was able to learn skills that will be useful as long as I live, as well as learn things like the previous generations did the, prior to automation of most equipment. That brings me to my breakfast.

My grandpa has always had a grist mill. As a child I would help him grind corn. We would travel to local fairs and demonstrate the grist mill for people. The other day he told me he was going to be grinding corn. I took this opportunity to show my 5 year old son how corn meal is made. We also decided to grind some grits while we were at it. That's where my breakfast comes into play. That bowl of grits was ground by 3 generations of my family and hand sifted by myself and my son. Hopefully he will pick up on some of the skills I learned as a child.

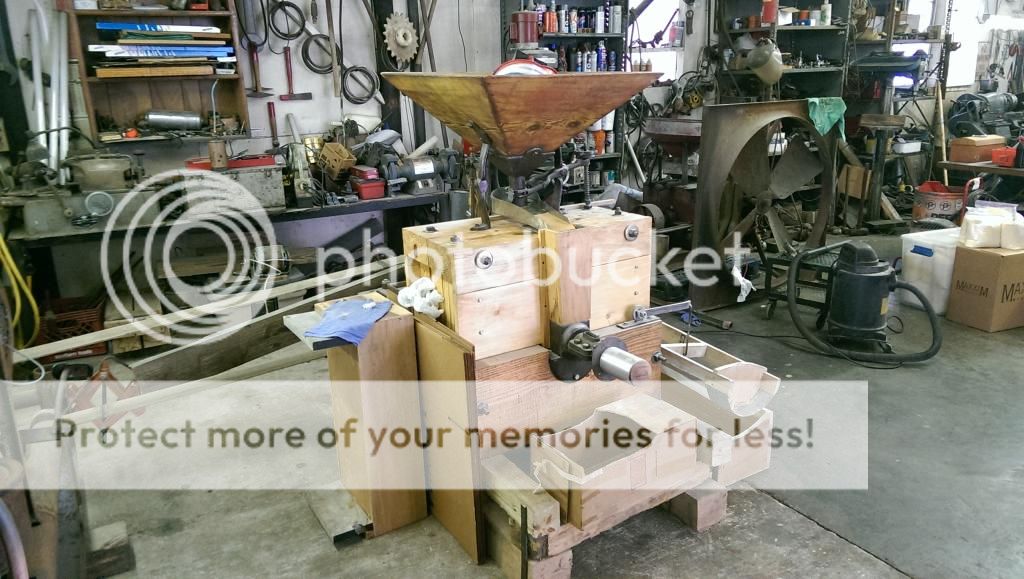

Here are a few pics of the operation:

Here is the power plant. It is a straight 6 and 3 speed transmission from a late 40s Chevrolet pickup. It has a short driveshaft connected to a large flat pulley. The canvas belt drives the mill.

The belt drives the mill. The shaft has stones attached to it inside the wooden box. You can adjust the tension on the stones to change the texture of the corn meal. If you adjust it out far enough it will grind grits.

The corn goes in the hopper on top. The corn feeds down a chute from the bottom of the hopper. You can adjust the amount of corn fed to the stones by adjusting the chute's distance from the hopper.

Once the corn goes down the chute, it hits the stones, is ground, and comes out the opposite end. It drops into a mesh shaker. The husks and bigger articles are held in the mesh. The meal falls through into a box below. There are several cams and rods off of the main shaft. One of them connects to the mesh shaker. It shakes it back and forth, helping the meal fall through the mesh. The husks and everything else shakes to the end of the shaker and falls into a separate box.

And here is a short video of the operation. We have a bag over the discharge. At the time we were adjusting the stones to grind grits. We had to check the consistency as we adjusted the stones. It's not on youtube, so I couldn't embed.

Here is a link to it on my photobucket

Win a FREE Membership!

Win a FREE Membership!