Quote History

Quote HistoryQuoted:

same here. laminate on my extension is also peeling away. finishing a couple of projects and then plan on fixing it

View Quote

Mine is 10 years old and has had the same thing going on for the past three years. I keep planning to getting around to doing something about it. Then I don't. It's just enough to be an annoyance, but not enough to mess things up such that I would be compelled to address it right away. So you have company.

Otherwise, it's a well built saw that is a joy to use. I am glad I sprung for the ICS base. Works great; whole thing moves like butter.

I also break down sheet goods with a tracksaw on a sheet of foam. It's a back saver.

The table saw is mostly used when things get smaller and/or more fiddly. An example of which might be long rip cuts in narrow material, or cross cuts via sled. I have not used mine to break down sheet goods, and cannot immediately recall needing cross cut capacity beyond what my 36" has. That said, every table saw eventually becomes as much a table as a saw, and I doubt the extra table length would be regretted. Congrats on your purchase of an excellent saw!

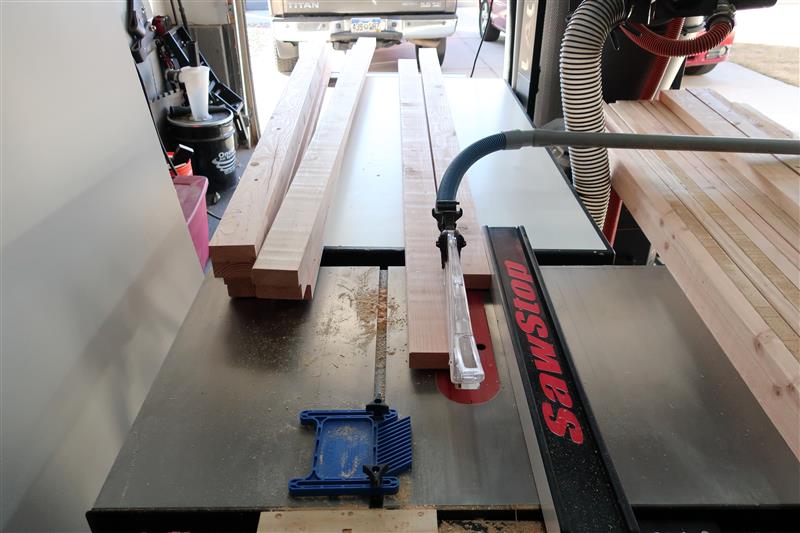

Couple pictures of mine in use:

Win a FREE Membership!

Win a FREE Membership!