I'd like to brag a little about some of my do-it-yourself work on my Kimber 1911 Stainless Ultra Carry II. I am not a machinist or gun smith, nor do I play one on TV. However, I have experience with hand tools, and most of all, I am patient.....

This pistol is special to me; My uncle, who was also my shooting mentor since I was young, carried this gun for a few years, and I liked shooting it so much that he gave it to me on my 21st birthday. I've carried it myself for the past 10 years, and have always been a 1911 fan. I got started in IDPA with this pistol, and these competitions led me to 2-gun, 3-gun, training classes, and eventually into 1000 yd shooting, all the while meeting a lot of new friends along the way. When my wife was pregnant with our son, I had a Wilson Combat CQB custom built for me as my final "carefree adult" purchase, and I finally had a top tier 1911. But I still carried this Kimber and remain fond of it.

After being carried for so long and running through many IDPA and 2-gun matches, it was starting to look a little beat up. I finally decided to have the frame refinished, and if I was going to do that, I might as well freshen it up with some other features that I enjoyed on my Wilson CQB. I watched about 100 Youtube videos; ordered a 30 LPI checkering file and 60° needle file from Brownells; an Ed Brown frame rebuild kit, Wilson Combat grip bushings, and Wilson Combat grip screws from Midway; a set of tiger stripe Operator II grips from VZ Grips; and a 30 LPI, aluminum, round butt, one-piece mainspring housing/magwell from Wilson Combat. Then I let the parts sit for a week or two while I worked up the courage to start cutting into the aluminum frame of one of my favorite guns.

I checkered the front strap, added the Wilson Combat magwell with frame and magwell blending, chamfered the safety to more comfortably interface with the web of the thumb, replaced all springs, screws, bushings, and pins, and had the frame Cerakoted in black. The slide remained as-is for a two-tone look.

The pistol when I started (with the VZ grips mocked up):

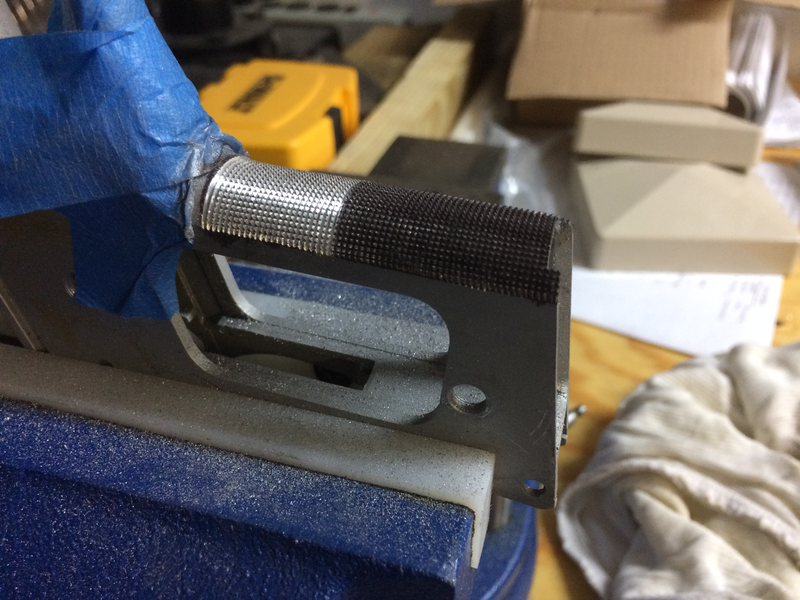

After the checkering the rough pattern, I went back over the grooves with the needle file to clean up the points and bring the grooves to final depth. Sharpie marker is what this non-machinist uses in place of Dye-chem:

The complete checkering and a small, cleaned-up finger groove under the trigger guard:

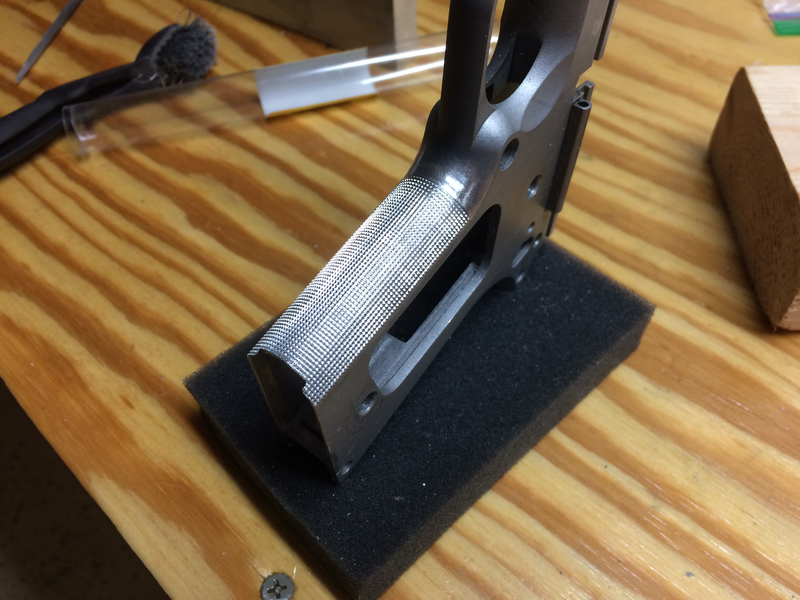

Blending the frame with the Wilson Combat round butt mainspring housing / magazine well:

The Wilson Combat magwell comes with a healthy chamfer, but the Kimber already had a chamfer on the frame. I wanted this work to look professional and wouldn't be satisfied unless these two were blended together. So, I took another deep breath and started filing into metal.

I forgot to take an after-photo of the magwell blend before Cerakote, but here is what it looks like all finished. The magwell funnel is awesome; it's super deep and helps with those speedy reloads. A well-blended magazine well warms my heart. I wanted to model it after my full-size Wilson CQB's funnel, but unfortunately, I couldn't go as deep on the rear. The sear spring slot is closer to the butt of the gun on the Kimber's compact frame, so making the funnel as deep as a full-size frame would cut through the rear frame wall and into the sear spring slot.

The stock thumb safety was too always thick for my hand and created a sore spot on the web of my thumb during prolonged range sessions. I chamfered it a bit to prevent it from digging into my hand. Last was a final sand to remove some big scratches and then off for sandblast and refinishing. Here is the pistol reassembled for fit and function checks:

The frame and all the controls were done in black Cerakote. The Cerakote tightened up the frame-to-slide and grip safety interfaces, so I put some oil on and ran a few hundred actions on both to clean them up.

I'm proud of my work and ecstatic about the Cerakote and final product. It feels like I have a new gun! I'm happy to give this pistol a tasteful refresh and hope to carry it for another 10 years

Win a FREE Membership!

Win a FREE Membership!