|

Posted: 1/14/2019 10:20:11 PM EDT

Having successfully repotted tubes in the past I intend on taking it to the next level.

The basics of potting are pretty straight forward, however the long term success of a tube repair lies in the details, if ignored a repot will last a couple of months or a couple of years at best. Doing it right is worth it. Let's start with the diagnosis: There are three main categories of tube failures, the first and easiest to fix is a failure of the potting material, where a tube will usually short-circuit between the MCP and Phosphor Screen. Tubes with this problem are identified by: The power-supply is drawing a healthy current between 20 and 40mA and the tube is flickering. The fix here is a repot. The second category is a PSU failure, either delivering a too low voltage or no power at all to the tube core. Tubes with this problem are identified by: The tube doesn't light up at all and the current drawn is outside the normal range, either close to zero or way above 40mA indicating an internal short-circuit within the PSU. The fix here is a repot and PSU replacement. The third category is a tube core failure, where the tube has cosmetic/visual damage beyond usability, or a leak where the tube lost it's vacuum, or physical damage to the input/ output window. Tubes within this category are identified by: visual image is unusable but remaining areas indicate a healthy PSU or the tube doesn't light up at all yet the PSU draws current within it's normal operational range of 20-40mA. The only fix here is to salvage the PSU. Once diagnosed, the tube is taken apart. Some people try to reuse the tube housing, but that makes this process really difficult. Because the only practical way to take a tube apart is by force. Separated from the tube housing, you'll be holding the potted tube core and PSU. The next step is to remove the PSU from the tube core by desoldering the wires and prying off the PSU from the tube core. The following step is also the most time consuming one, cleaning off the potting material. To be noted here, do NOT use any metal objects in this process. Scratching the ceramic surface of the tube with metal objects can cause the repot to fail due to metal trace particles left on the surface of the tube. A sandblaster is of great help for this step, just don't forget to tape off both optical ends of the tube. Once clean, wash the tube in distilled water then rinse off with lab grade isopropyl. With the tube core, PSU and tube housing ready to go. It's time to solder them back together and getting ready for the RTV potting. Make sure your RTV potting silicon is rated at 12kV/mm or higher. Mix the RTV and place both the tube assembly and the RTV mixture in a vacuum chamber. This has two reasons, you degas the potting mixture, meaning getting the air out of the silicon ensure the material won't lose it's dielectric strength and secondly by also placing the tube in a vacuum before potting, you remove any remaining surface moisture on the tube core. (L3 wisely chose Tempe as it's location for their tube plant, the air is really dry there most of the year around) Trapped moisture between tube and the RTV can easily lead to arcing. It's now time to pot the tube, tape off the bottom of the tube, fill up the fitted tube with the degassed RTV using a syringe and place it back inside the vacuum, letting it cure for 24h. Once cured, you will most likely need to re-adjust the feedback and ABC potentiometer. First adjust the ABC to a light level of your liking, then carefully probe the feedback potentiometer until you are happy with both the noise level at low and high light conditions. An optical tube test setup is extremely useful at this stage. Done. In case you call yourself the owner of a broken tube then your tube deserves a second chance. Pm me and let me breathe new life into it or hit me up with questions if you want to give it a go for yourself! I am looking for all kinds of broken tubes and tube parts. |

|

|

|

[#1]

If there is any way you could make a video of you doing this on your next one, me would love you long time....I find shit like this fascinating.

|

|

|

|

[#2]

Good summary. Also good to see more people repotting tubes. Probably can count the number of people who repot tubes on one hand, maybe have to start using another hand now.

|

|

|

|

[#3]

Quoted:

If there is any way you could make a video of you doing this on your next one, me would love you long time....I find shit like this fascinating. View Quote Quoted:

Good summary. Also good to see more people repotting tubes. Probably can count the number of people who repot tubes on one hand, maybe have to start using another hand now. View Quote |

|

|

|

[#4]

how toxic are the chemicals involved in the process? I've known a few users who said they were pretty toxic so they scrapped the idea.

|

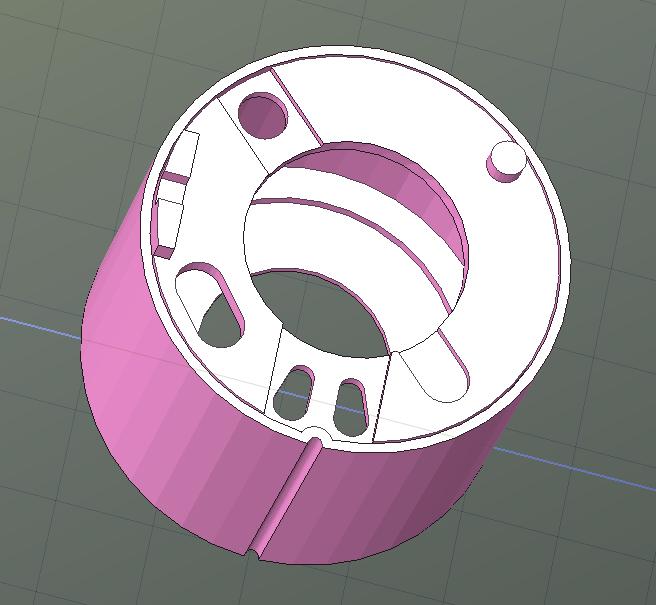

|

|

|

[#5]

|

|

|

|

[#6]

Quoted:

how toxic are the chemicals involved in the process? I've known a few users who said they were pretty toxic so they scrapped the idea. View Quote http://www.farnell.com/datasheets/1521089.pdf You can almost drink the stuff ( not recommended ) and it's usually only considered bad if you get it in your eyes, so it's safer than most of the stuff you'll find the the average kitchen. David. |

|

|

|

[#7]

Quoted: You do need to be careful in case you break a tube core, you don't want that phosphor getting anywhere. View Quote Good write up. I'll add that, for home brews, if you set up your jigs correctly it is possible to pour the elastomer with excellent results at atmospheric pressure once degassed, also you need to refer to boiling temps vs vacuum levels if you want to dewater the parts by vacuum without low-temp baking, and that requires better vacuum equipment than most people have ready access too. For DIY at home, you can degas the elastomer by 1/4 filling a 100mm syringe with the mix, after mixing, and then pulling on the syringe to create a vacuum several times while the end is stoppered. Doing it a few times will also cause shock to the bubbles which will help smaller bubbles form larger ones. Letting the stuff cure in a container and then cutting it open prior to doing a run on tubes allows for microscopic evaluation on bubble levels so you can fine tune the process. Field potting methods are quite suited to amateur repairs without requiring complex setups. Generally I find the biggest impediment to new attempts at repotting is finding a ready supply of boots to fit everything into prior to potting. David |

|

|

|

[#8]

Quoted:

Hi Alex, Good write up. I'll add that, for home brews, if you set up your jigs correctly it is possible to pour the elastomer with excellent results at atmospheric pressure once degassed, also you need to refer to boiling temps vs vacuum levels if you want to dewater the parts by vacuum without low-temp baking, and that requires better vacuum equipment than most people have ready access too. For DIY at home, you can degas the elastomer by 1/4 filling a 100mm syringe with the mix, after mixing, and then pulling on the syringe to create a vacuum several times while the end is stoppered. Doing it a few times will also cause shock to the bubbles which will help smaller bubbles form larger ones. Letting the stuff cure in a container and then cutting it open prior to doing a run on tubes allows for microscopic evaluation on bubble levels so you can fine tune the process. Field potting methods are quite suited to amateur repairs without requiring complex setups. Generally I find the biggest impediment to new attempts at repotting is finding a ready supply of boots to fit everything into prior to potting. David View Quote Great idea with the syringe! Agree on the boots, I am considering investing in a plastic injection mold for this reason, as this will give by far the best results. |

|

|

|

[#9]

Quoted: Hi David, Great idea with the syringe! Agree on the boots, I am considering investing in a plastic injection mold for this reason, as this will give by far the best results. View Quote Also, I can put you in contact with a very affordable molder and toolmaker, if you ever want to get into that. |

|

|

|

[#10]

Yes, you can 3D print boots quite effectively. The walls are a little thick of FDM printers, but they come out OK and still work.

|

|

|

|

[#11]

|

|

|

|

[#12]

Quoted: Nice. It seems like it would be cheaper for low volume to print boots. And easier to make some of various dimensions. View Quote

(MX10130 boot) Except stuff like this is often ITAR controlled and there are even other laws about sharing this kind of stuff now... So pretty much if you want something like this, you either have to design and print it yourself, or control the files, or buy from someone who makes them. A long time ago I put up a generic MX10160 boot - a very early example - and I think it's still the only one in the public domain, and while it works, it is pretty terrible. It would be ideal if stuff like this could be spread around to help. It's worth keeping an eye on what happened to Defence Distributed. https://defdist.org/ Hopefully one day ITAR will be amended to allow things like this to enter the public domain. |

|

|

|

[#13]

fortunately, boots are fairly easy to draw in cad, so 3d printing them is viable.

|

|

|

|

[#15]

Quoted:

The problem is ITAR. Sharing stuff like this should be practical; http://aunv.blackice.com.au/userfiles/david-boot2.jpg (MX10130 boot) Except stuff like this is often ITAR controlled and there are even other laws about sharing this kind of stuff now... So pretty much if you want something like this, you either have to design and print it yourself, or control the files, or buy from someone who makes them. A long time ago I put up a generic MX10160 boot - a very early example - and I think it's still the only one in the public domain, and while it works, it is pretty terrible. It would be ideal if stuff like this could be spread around to help. It's worth keeping an eye on what happened to Defence Distributed. https://defdist.org/ Hopefully one day ITAR will be amended to allow things like this to enter the public domain. View Quote Quoted:

fortunately, boots are fairly easy to draw in cad, so 3d printing them is viable. View Quote Admitted ITAR is serious business (licensed 07/SOT and accessory producer here). And it does hamper productivity of honest people. |

|

|

|

[#18]

Quoted:

So turns out the image intensifier that wouldn't light up had a faulty PSU. I tested the core using a working PSU by submerging the core in mineral oil. (be sure to clean off the oil using a solvent) Turned off the lights and the thing glows bright as ever. And it appears to be a pretty flawless core, no spots. Next up is giving this core a second chance using a new PSU and repot everything. https://imgur.com/lkusnDs.jpg https://imgur.com/KcSIyW3.jpg View Quote |

|

|

|

[#19]

Quoted:

So turns out the image intensifier that wouldn't light up had a faulty PSU. I tested the core using a working PSU by submerging the core in mineral oil. (be sure to clean off the oil using a solvent) Turned off the lights and the thing glows bright as ever. And it appears to be a pretty flawless core, no spots. Next up is giving this core a second chance using a new PSU and repot everything. https://imgur.com/lkusnDs.jpg https://imgur.com/KcSIyW3.jpg View Quote One night some years back I bought half a dozen bottles of baby oil and some decently large tupperware containers for submerging a 100kV x-ray power supply. Cashier lady gave me the strangest look. |

|

|

|

[#21]

|

|

|

|

[#22]

This is pretty amazing. There are many stumbling blocks to this procedure. Not only is it labor-intensive, and requires specific tools, tooling, and supplies, but it also is discouraged if not out-right prohibited by government agencies, mfg's, and maybe others. So I would say kudos to you guys for pushing out the boundaries of our knowledge here.

This is pretty fascinating stuff. Some of you may remember Toffler's "Future Shock" which is the point where technology comes at you so fast, you don't have time to comprehend it. Night vision has always been that point for me. I could never quite get the idea out of my head that it came from crashed alien technology; it's just that amazing to me. I know you kids chuckle at that, but you are from a different generation. There are also those with a vested interest in keeping this technology secretive, not only from a security standpoint, but an economic one as well. And I tread lightly here because they are those who have given much time and effort to educating the public, on at least using NV, and make a living selling it, that I don't want to be an ungrateful turd. This forum is due to the efforts of some of these people. So perhaps this is where hobby goes a separate path from professional use. Those that want to "roll their own" can endeavor to do so, while those that buy professional grade gear will continue to do so. And this is not to denigrate the efforts of you amateur "potters"; I make tactical nylon gear myself and have experienced the various attitudes towards home-made gear. Just to say, as in any technical endeavor, there is a learning curve, and lots of time and money to get to a professional level. Good luck to you guys. |

|

|

|

[#23]

|

|

|

|

[#24]

Quoted:

What is the purpose of submerging in oil?0 View Quote |

|

|

|

[#27]

|

|

|

|

[#28]

Pic of the back of the old PSU please?

Looks like an old Litton PSU. Wire colors are Litton/L-3. |

|

|

|

[#29]

Quoted:

https://i.imgur.com/ZV1phfil.jpg https://i.imgur.com/gWAIYT7l.jpg https://i.imgur.com/fY2akmYl.jpg Who fancies blue tubes? The RTV mixture is degassed for around 10-15min at -25 Hg. Once the tube has been potted, I degas the tube for another 20min at -10 Hg and let it cure for 24h in open air. 3D printed booths work very well as you can see, I had to adjust the design a bit to account for the wall thickness limitations of 3d printing. View Quote |

|

|

|

[#30]

|

|

|

|

[#31]

The last guy that posted really good informative stuff about repotting tubes mysteriously disappeared... ????? Be careful because this place has a history of deleting really knowledgeable people.

|

|

|

|

[#34]

Great work Alex!

What type of filament are you using to print the boots? |

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.