Here is a quick DIY I threw together on how to make a mount for either a Surefire Scout or Steamlight Pro Tac light to be mounted to your team Wendy helmet in conjunction with QD Peltor adapters. This will also work with a Princeton Tec Switch/Point by simply adding velcro to where the Scout would typically be mounted. Hopefully this DIY will make sense and some people get some use out of it. You can make a handful of these mounts for about $12

Materials:

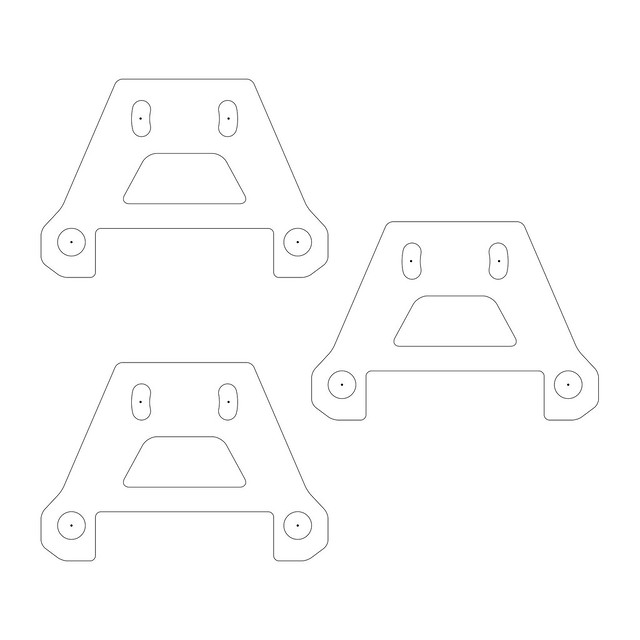

The template I provided

16ga Steel, I picked up a 18x6 plate at Lowes for $7 (its where their angle iron is)

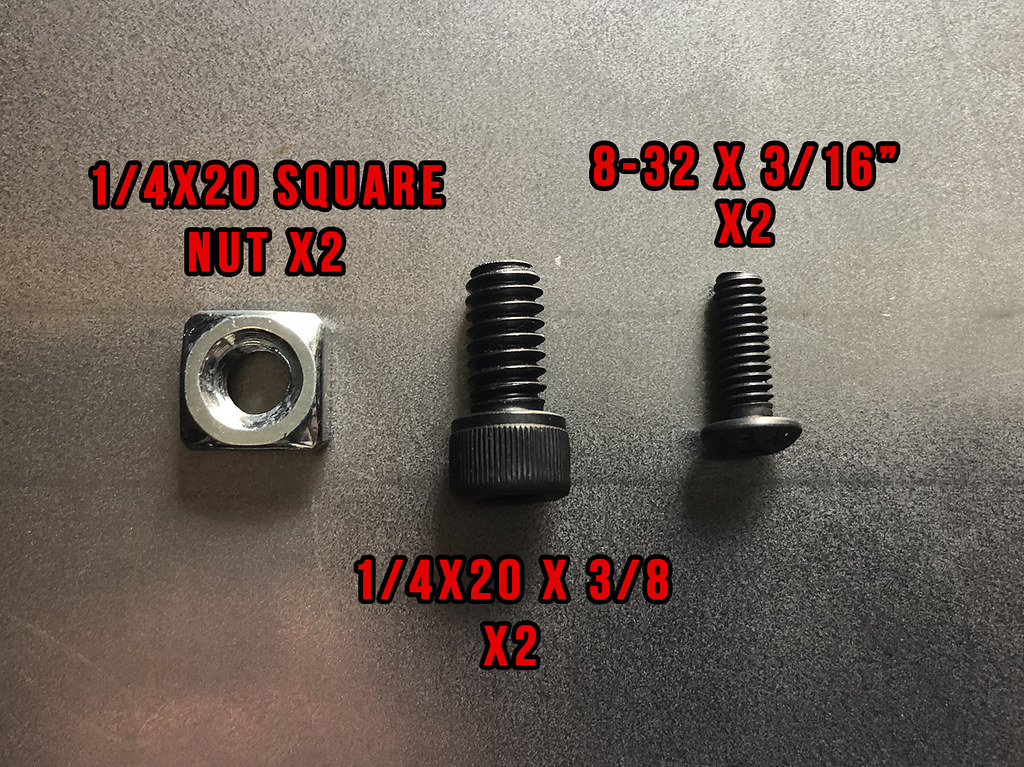

2x 1/4x20 by 3/8" bolts

2x 8-32 x 3/16" button cap bolts

Tools:

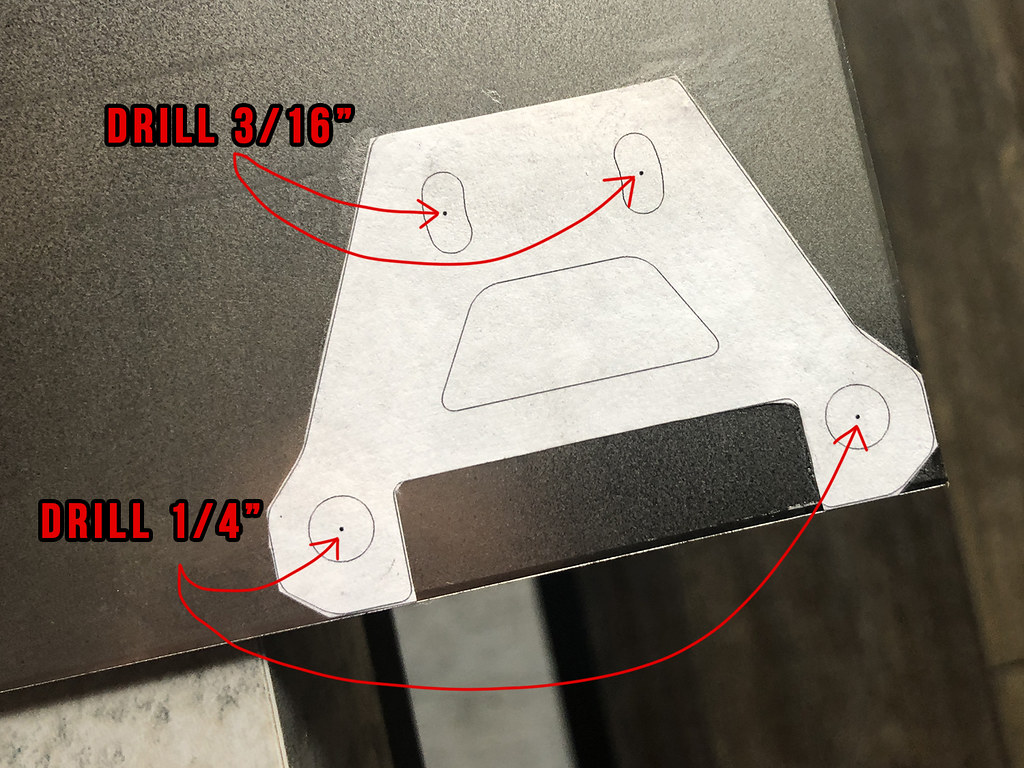

Auto Punch

1/4" Drill Bit

3/16" Drill Bit

Dremel with metal cutting disks, sanding drums and some small grinding bits

Sand paper

Paint, cerakote, plasticip or whatever you want to coat it with.

Start buy cutting around the outside of the template and gluing it down to a corner of your steel plate. Then center punch each of the tiny black dots (four in total) Then go ahead and drill out each hole. After that you can cut out your plate.

After you get it cut out, you want to make sure all your holes line up. If they don't, use a small grinding or cutting bit to open your holes in the direction they need to be moved. You can also oval out the front Scout hole in a vertical direction to allow angular adjustments of your light.

When you are all done and you've checked alignment you can clean up all the edges using a sanding drum on a Dremel. Then go ahead and sand both faces of your plate to prep for paint. Clean it well then coat it however you wish. After you are satisfied with your coating you can mount your light to the plate.

Then drop the square nuts in the rail system and mount the plate to the helmet.

If you have a vice, I would recommend putting a slight bend in your plate to get the light even closer to your helmet.

Win a FREE Membership!

Win a FREE Membership!