Quoted:

Do you guys think that an aluminum screw 1/4-28 1/2" is strong enough for the pistol grip? I'm building a lightweight rifle.

View Quote

Im no expert, these are my thoughts.

I would think that a 1/4" aluminum screw would be sufficiently strong for securely attaching the pistol grip to an ar15 lower. The way the grip interfaces with the lower was done well by design, it removes the potential of putting a shear load on the bolt. Impacting the grip from the side would put large percentages of the force on the upper tabs of the grip and the lower receiver itself but not much on the bolt. Impact on the bottom front of the grip towards the buttstock would probably put the most force on the grip screw as the mounting surface at the top rear of the grip becomes a pivot point and the grip itself becomes the lever. The bolt is still resisting destruction through tensile strength in that scenario. I googled to try and find tensile strength at yield for an aluminum 1/4 28 bolt but got tired of searching. So i calculated it.

Formula

ASTM specs

Using formula (yield min x stress area of the specific diameter = yield strength)

ASTM F468 UNS A96061 machined has a Minimum yield strength of 45,000psi

A 1/4 28 bolt has a stress area of 0.0364

45,000 x 0.0364 =

1,638 lbs

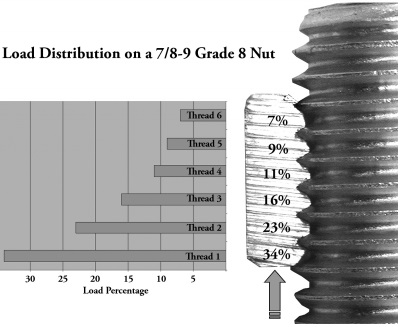

As far as the bolt length, that will depend on the grip you are using as some of them have more material than others at the mounting location. The first 6 threads do all the holding, after that the fastener will fail before the treads will.

With a 1/4-28 bolt 6 threads is about 0.214" so as long as 1/4" of the bolt is threaded into the lower you should be good to go.

With statements like, "i think" and "should" people always tend to lean towards, "definitely" and "absolutely". Titanium has a far superior yield strength and is certainly overkill for the application but provides cheap insurance for those that don't like to innovate.

Hope this helps.

Win a FREE Membership!

Win a FREE Membership!