|

|

I dont see this item being applicable, unless you have a really narrow gun and its not in the center of the case, i dont see it working on any Pelican 17xx gun case. |

|

|

|

|

For those that don't want to build one.

http://hotwirefoamfactory.com/product.php?productid=16140&cat=3&page=1 |

|

|

|

what is a good adhesive that would adhere the foam to the side of the pelican case? Also foam to foam adhesive?

|

|

|

Ok thanks I have not gotten my case yet. But its on its way. So i don't know how thick the foam is or how my rifle will lay in it. I just like to get a cutter before my case shows up. I tried to make one like on the first page but the wire now will not get hot enough now. I woundered if i used to small of stranded wire from the battary can to the cutting wire. and i am losing power because its to small of wire. E3 |

||

|

|

|

I had the same problem but it was the batteries , i bought new batteries and it heats up right away, and i went through 6 batteries and about 3 hours just on my rifle, ill have pics when my other mag comes.

|

|

|

|

|

Use a multi voltage DC transformer from radio shack as the power source. They go from about 3-24VDC or so. That will allow you to adjust the voltage for the resistance of the wire you are using to get it at the right temperature. |

|||

|

|

Me too! However, after butchering my first Pelican with a utility knife, I decided to build a "hot wire cutter" this time. I bought one of the tools from the Hot Wire Foam Factory and modified it for my use. It was a great project for my 12 year son and myself, as the time spent together was worth much more than the $55 spent. Check out the pics and tell me what ya think. I would love to see more detailed pics of your cutting setup... Nice job!!! |

|

|

|

|

Nothing fancy. Built the base from plywood and 2x2's (idea there was to keep it light and low). A four foot section of aluminum U-channel and flat stock to erect the cantalever (or crane if you ask my son). The Foam Factory tool is very simple, it bassically has + & - terminals, an off & on switch and plugs into a standard 110 outlet. I have a bolt with several nuts and washers (which allows precise adjustment of the cutting wire) on the bottom side connected to one terminal. The other terminal is connected to an eye bolt on the cantalever. I drilled a hole thru a rubber plug to isolate the eye bolt from cantalever. A spring hangs from the eye bolt and adds tension to the cutting wire. I'll probabbly add a couple more coats of polyurethane to help the foam glide around. It's worked well so far, and I suspect that several of my buddys will quickly get in line.

|

|

|

|

I bought one of these HOT WIRE CUTTER and made a simple table to clamp a straight edge to. Works great and does not take up much room when not in use.

|

|

|

|

So I finally completed my cutout on my Pelican 1720 case. Lemme say what i would have done differently... Spent more time properly setting up my wire cutter, Putting a spring so the tension on the wire would be tighter, and having a bigger platform/base. I went through 8-D batteries and my ar 15 alone took about 3 hours to cut out. My magz i cut out was to big and was sloppy because my cutout/stencil was to big so i ordered another one to make it tight, as it worked well. I use Styrofoam glue to glue my foam together so it wouldn't pull up when i pulled my gun out. I was going to cut in a cleaning kit below the rifle but decided not do that (thats why the rifle is up higher). Ill probably end up cutting out another foam piece down the future when i get a suppressor and EOTech. I had fun doing this project, it was a pain in the ass to do it the first time but when i do it again i know it will go much easier. I had to cut out the 2nd piece (the lower) foam where the hand guard and bi pod is so it would sit deep inside my case without having problems closing the lid. I think it turned out good for a first timer, obviously if i do it again it SHOULD go smoother and more easier, and more time efficient.

|

|

|

|

Im going to build my cutter tomorrow but I have a question.

I want to use the AC/DC multiple power adapter they sell at radio shack (goes from 1.5-12V) versus the D size styro cutter. I'm handy but I have very little experience with electricity and a project like this. My design would look like this:  Do you think this will work or is there something I am missing? The feed wire and the florists wire will be connected using the same bolt/screw method most have have used on this post with success. Thx in advance guys ... |

|

|

Its $18.00 at radio shack ... |

|

|

|

|

|

So, how did the Radio Shack adapter work? |

|

|

|

I will be setting it up later this week ... |

||

|

|

|

What about using the ballast for a florescent light to power the cutter? Anybody think

that would work? I do not know anything about electricity, but someone brought this idea up to me last night and I wanted to ask on here to get some input on it. |

|

|

|

|

|

That is the same kind of board I made my top out of. I used an old table that I was

going to throw away and topped it with the eucaboard with liquid nails and some screws and beveled the edges. Will post pics when I get the power supply set up. Total cost so far is $10.00 |

|

|

|

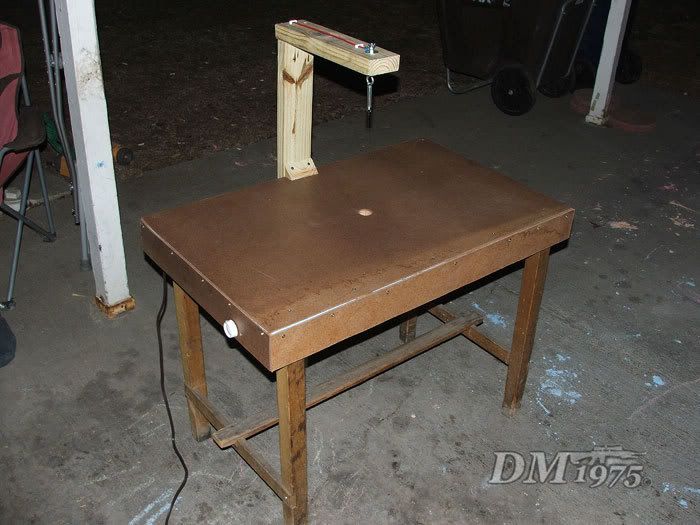

Ok, got my table complete besides the wiring. Going to run a transformer and a dimmer switch to it when I get the stuff. so far I think I have 10 or 15 dollars into it including the doner tabel I used to convert. Had a little help from fellow ARFCOMMER ndt in building it as well. Not much but it didn't take much either.

|

|

|

Looks good. Pretty cool to see the variety of solutions people have come up with. Let us know how it works! |

|

|

|

|

it

nice work guys. last week was the vacation week i was going to get all my do-it-yourself shit done. then the boy got sick, who knew a 2 year old could shit so much oh the joys of fatherhood. |

|

|

|

I finally cleaned up the mud on the case JUST FOR YOU GUYS

Had to cut out slots for my new PMags last night (greatest mags ever, IMHO) http://farm4.static.flickr.com/3084/2327122017_857388cfea_b.jpg http://farm3.static.flickr.com/2331/2327121081_deb2274ee4_b.jpg http://farm3.static.flickr.com/2345/2327936832_c819a36462_b.jpg |

|

|

|

OK, crappy night photo but here is my "for now" complete EBR 5000 Gun Case Foam

Cutter and after all of the parts I have a whopping $25.00 and a free tabel invested into this. I cheat a little bit because all of the wood came from the scrap pile at Home Depot and I think it was all 70 or 80% off of cost. Only problem is I was using guitar wire and I was popping them like crazy cutting the foam so I have to get some nichrome wire or learn to set my tension or heat better. I will also be painting this and making some EBR decals for it too

|

|

|

|

Here are some pictures of one that I made. It is crudely made but it does the job. I made it with wood leftover from some other projects. Best of all it cost me only $5.00.

http://i247.photobucket.com/albums/gg143/fedman_photos/FoamCutter3.jpg http://i247.photobucket.com/albums/gg143/fedman_photos/FoamCutter2.jpg http://i247.photobucket.com/albums/gg143/fedman_photos/FoamCutter1.jpg |

|

|

|

I am going to use a 2/4/6 battery charger for my setup,being as I have no electrical knowledge I have one stupid question..

When hooking up the terminals of the charger,do I just hook up the red one to where the cutting wire is (underneath the board)and ground the black one,or do I need to make a continuous loop (hook the black one up to the wire support arm ) |

|

|

|

OK guys, question for you. I hooked it all up tonight with better wire and fired it up. I

started to cut foam and then POP!!! Transformer blew out... WTF over? Any ideas? What did I do wrong and what do I need to do to fix it from doing it again? I wired it up as others have with the dimmer switch and transformer and all connections were correct. Thanks. |

|

|

|

I originally tried it with a hobby train transformer. It was heating up and then the transformer also blew. Ever since I've been using the batteries and it works great.

|

|

|

|

Thanks, but I would like to keep this on wall power if at all possible.

|

|

|

|

For those building their own, or at least thinking about it, and are unsure if you want to try the transformer/dimmer method, as I found out, it really is the best way to go.

First, I tried the ac/dc method (I already had a box of a bunch of different voltage ones). The end result is that I couldn't get it to go. I'm pretty sure it has to do with such low amps coming out of them (most in the 300-500mA range. Even the 12v, 1A one just couldn't pull it off with the florist wire I was trying to use (0.035" thickness). Of course batteries are an option, but with batteries, you cant control how hot your wire gets, except to either lengthen or shorten your wire, use stronger/weaker batteries, or use thinner/thicker wire. I had a bunch of batteries, and I just couldn't find a good combo I felt comfortable using, either being too hot or too cold. I would just hate to be in the middle of a long/complicated cut and find out my batteries are dying.... I admit I dont know a lot about AC which is why I was reluctant to even try the transformer/dimmer method, but after doing so, its very easy and definitely the best method to go with. Now I dont have to worry near as much about the thickness of wire, batteries running low, or even wire length. Just a simple turn of the knob to the temp I feel comfortable with and you're cutting. Just follow mfingar's instructions on the first post and you cant go wrong with it. I wasn't too comfortable using the metal pole method and made mine with wood. I would strongly recommend using a spring though, either directly in the line, or keeping pressure on a swiveled mount, as once the wire heats up, depending on length, it can get a bunch of slack causing sloppy lines. Anyway, I mostly wanted to thank mfingar and everyone else for such great ideas and tips. Now I just have to wait for Magpul to release the UBR so I dont have to recut my foam... |

|

|

|

Fab ideas! Question: wouldn't a soldering iron (secured to the wood surfaces that you all invented) work to heat the wire as well? Let me know.

|

|

|

i was pondering this as well.... not sure if you'd have much temp controll though, and a transformer is cheaper than a ruined soldering iron... |

|

|

|

I toyed around with that idea myself and even took apart one of those cheap ones they give you in computer tool kits. After thinking about how long that thing takes to get up to temp, I decided to just leave it alone and do it the way thats been working for everyone else (transformer/dimmer). Looking through some of the previous pics (modern-militia on page 15), it does looks like he went that route. I suppose it would work if its able to heat up and cool down fast enough, but I believe it'd end up getting way too hot overall unless it was nice enough to have a temperature control (which you wouldn't be using it on this anyway if it was). I guess if you wanted to just mount the soldering iron and put the wire up against the heating element, that might work, but I think you'd end up loosing too much energy making it take too long to heat up. |

|

|

|

It worked so well on my Savage / Pelican 1750 set-up that I recently ordered a couple sheets of replacement foam for my Pelican 1720. I plan to do a couple different AR arrangements that I can swap out from one range trip to another. I bought the foam on ebay from CFS (custom foam solutions) over a week ago and haven't heard anything from them. Has anybody else bought replacement foam from them? Just to clarify on my set-up, the tool I used came from Hot Wire Foam Factory, it is not a soldering iron. |

||

|

|

|

Well,my battery charger method didn't work,the "fault" light came on everytime I switched on the power from the surge protector.There must be some sort of built in safety on the charger,this whole thing is one gigantic bucket full of fail for me

So...I just went to Radio Shack and got a transformer.it is bigger than the one Mfingar has..it says " SEC.12.6-0-12.6V 2A ",on the bottom line it says " PRI. 120v 60Hz" ,will this work without blowing myself up ? I just hope I can wire this thing right,this whole thing has become a major project and I feel kinda stupid not having done it after everyone else seems to have no problems.My living room is a complete mess with parts and tools all over the place..this is one of those times that I'm glad I am not married because she would have left me by now for a cleaner man.

|

|

|

Just make sure you have a dimmer switch in line so you dont fry your wire too fast and you should be great with that. Be careful and you'll do fine. I think most people are using 24v/2amp trans, so your actually a little lighter on the volt side, not that it should really matter for this. If you're really worried, plug your power cord into a surge protector with an indicator light so you have a double on/off switch (one on the dimmer switch and one on the surge protector). |

|

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.