First, I am not a 1911 guru by ANY streach. Most of what is written is my estimation from what I took from M1911.org. If anything is done incorrectly, feel free to comment.

Here are a few pictures of my father doing some work on one of my 1911s. What we are doing, is fitting an oversized Evolution Gun Works firing pin stop. The pistol in question is a relatively stock Kimber DW.

This is the piece from EGW

http://egw-guns.com/store/index.php?main_page=product_info&products_id=36&zenid=7654ced1af48207e128ca8602f9d6787

Here you can see the difference between the EGW unit (left) and OEM piece (right)

As the 1911 was designed from JMBs hands, this piece originally had a 90deg angle at the bottom of the FPS where the hammer comes in contact with it. This was the correct design.

However, a few years after the 1911s inception, some limp wristed GIs complained that the 1911 was hard to "rack" against the 90deg angle, and thus the bastardization of the modern FPS was born. A LONG and swooping bevel was introduced into the 1911s FPS. While this did make for easier cocking, it also made the shooter feel more recoil, and the pistol did not "track" as easily on follow up shots. Nearly ALL modern 1911s have the "bastard" improvement.

Remember that as the radius gets smaller, the more it resists the slide's rearward movement...and the more momentum it loses at the outset.

This is a $15 part that is the single best mod you can do to a 1911.

While it does require some fitting by a qualified gunsmith/machinist, it is well worth the time and investment.

The EGW unit was about 10-thou to large, and had to be ground equally on both sides to fit. Removing equal materal from both sides is DIRE as if this is not done, the Firing pin hole will not line up with the firing pin.

Correctly fitted, the new piece should have a snug fit, and take a small bit of pressure to be installed. There should be no play.

Also, I should comment, that the EGW unit was not exactly flawless. It required some shaping of its own. It was not entirely flat on both sides. A few min with a honing stone, and she was all better.

The stock FPS was about 7-thou to small, and was quite loose in its groves. Also, it should be noted, that if the FPS has excessive play, it will cause the extractor to "roll" in its slot, causing the pistol to not eject correctly.

A FPS with a snug fit is a good thing.

All of the EGW units are oversized, and must be fitted to match each individual 1911.

Also, we will be placing a small bevel on the 90. I have heard many opinions as to what this bevel should actually be. There is no general consensus, only that the edge is slightly broken.

This is the grinding wheel dresser that we will use to shape the grinding wheel to the correct bevel.This is such a fine piece. Made back in the 1940s. Dad still has the original bill of sale.

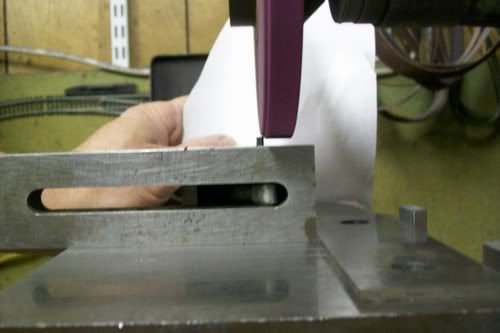

Dad dressing the grinding wheel.

From the side, you can see the dressed wheel, and it creating the bevel on the new FPS.

Here is the modded piece compared to the stock unit.You can see the slight bevel that was created.

Egw on left, stock on the right.

The EGW unit as fitted in its slot.

The picture seems to show the left side as being high, but it is not.

After fitting, I did some tests with a few friends. One has a stock Springer Loaded, and the other has a Colt WWI Repro. Both friends are knowlegable shooters.

All guns were shot by both friends. Both were amazed at the way the guns reacted when the EGW gun was fired compared to the others. One even commented that we had to be using different ammo. The pistol tracks so much better now. It has a crisp push, but all of the right "roll" was virtually eliminated.

Win a FREE Membership!

Win a FREE Membership!