Quote History

Quote HistoryQuoted:

You could also leave out the steel girder and simply use 16'-6" long cast-in-place pans. The down side to this method is that the labor and materials required to temporarily brace the pans, until the concrete set, might exceed the cost of the steel girder. It would take a lot of bracing to support that many tons of wet concrete.

View Quote

Maybe 10 man hours for a guy who knows what he's doing and a guy to help him ( hold stuff plumb while he nails it, cut material etc) for a deck that size.

Using either :

Ellis Shores (4x4s with a set of gravity clamps that bind up the 4x4s, and using 4x6 stringers and 4x4 joists and 3/4" plywood.

Or Shore-X/WACO shoring (like frame scaffold but stronger) and using 4x6 stringers and 4x4 joists and 3/4" plywood.

The plywood might be harder to rent but it's possible someone rents it . I could probably source some locally if I tried, but this is what I do for work so I know some people who could possibly make me a deal.

There are also systems where the plywood is panelized, like Peri Skydeck or Aluma-Systems Alumadek.

Rent enough material to get 99% of the deck done and then cut in 3/4" plywood fillers with a pinned on 2x4 ledger around 2 sides of the perimeter (2 sides of the box are Alumadek butted up to the existing concrete walls)

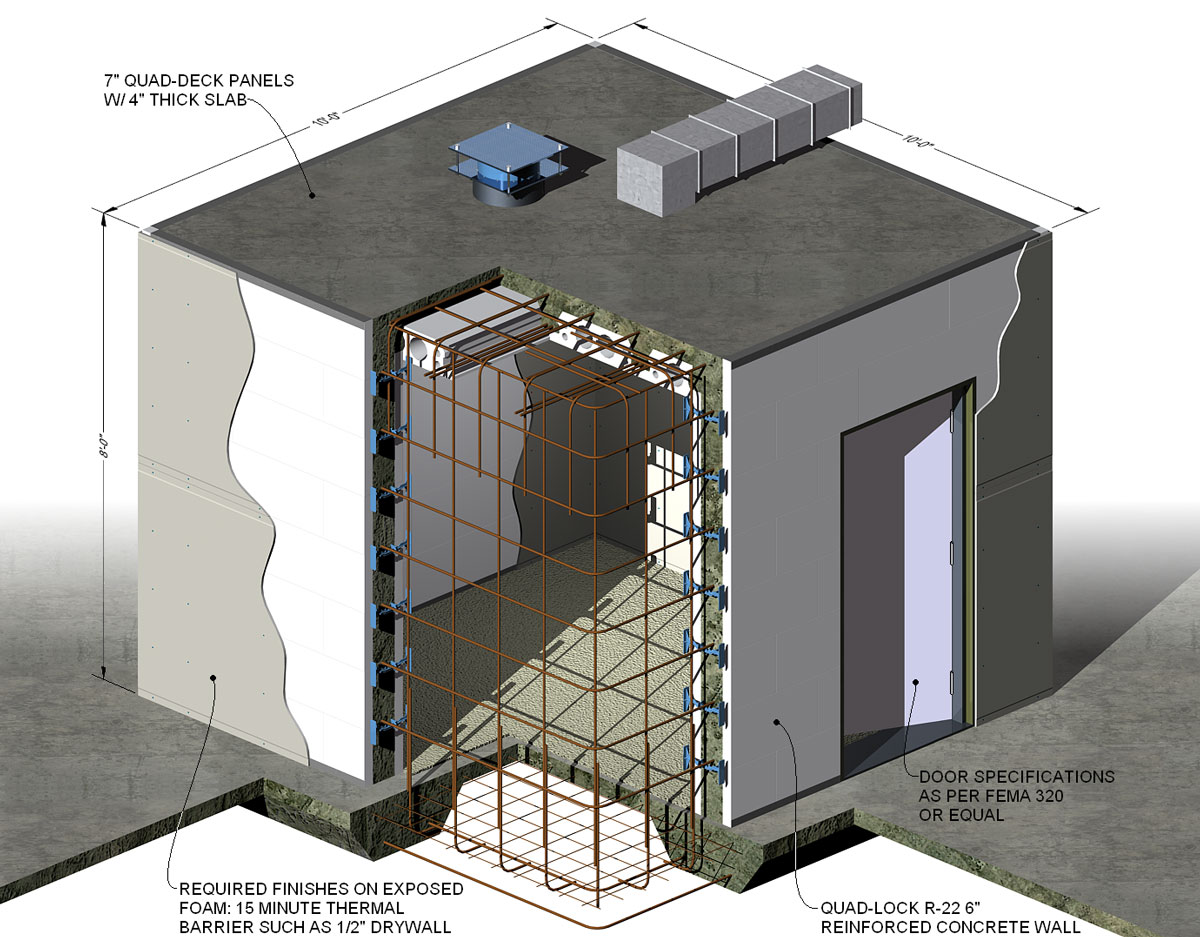

There are also the ICF forms which I think are pretty damn cool, but not practical in large commercial applications, but ideal for residential ones. Might be the solution for the OP, although I have no clue on the pricing.

There are a lot of options.

Dokaflex vs. Shoring Frames Time Trials

Win a FREE Membership!

Win a FREE Membership!