My house was built in 1952 and it has a wood floor that is around 2"-3" thick w/crawl space that I can easily access - with about 4' of space between the ground and the floor.

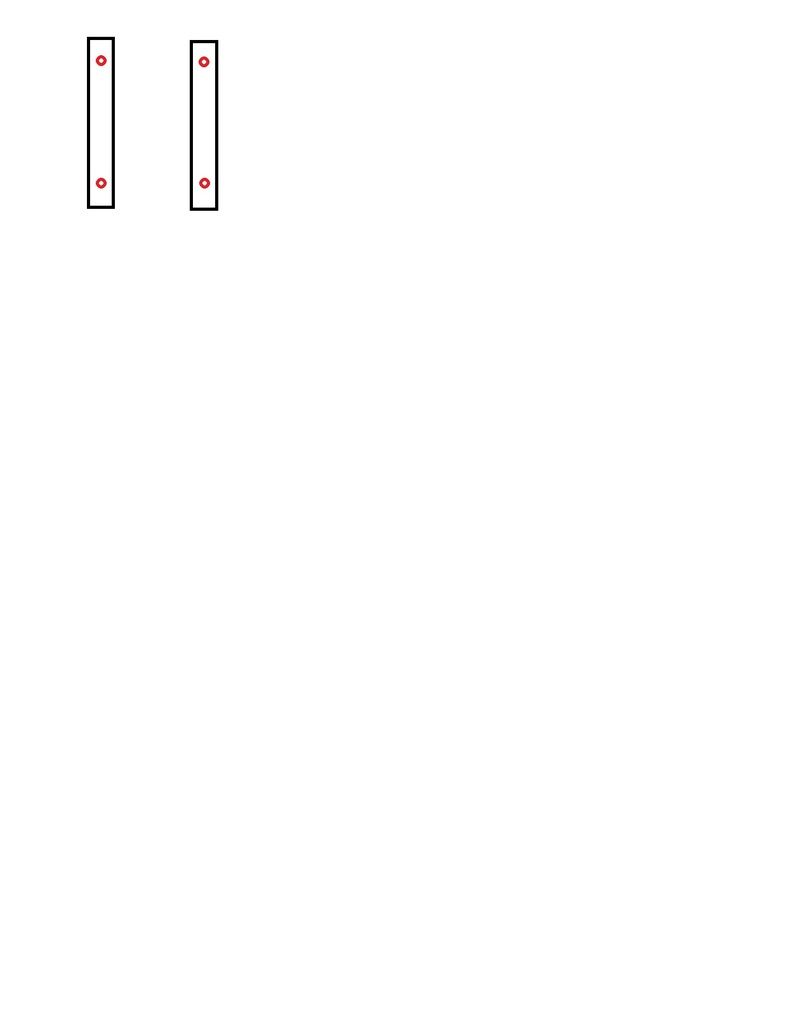

I have the safe in the closet and I plan on bolting it down with grade 8 bolts and using 2x6's under the floor with about 6" or so extending past the safe on both side like so...

My main question is and perhaps I am over thinking this but... Should I bolt it down with the threads facing up or down? Meaning should run the bolts from the floor up - tighten the nut inside the safe or run the bolt facing down from inside the safe - tighten the bolt from under the floor?

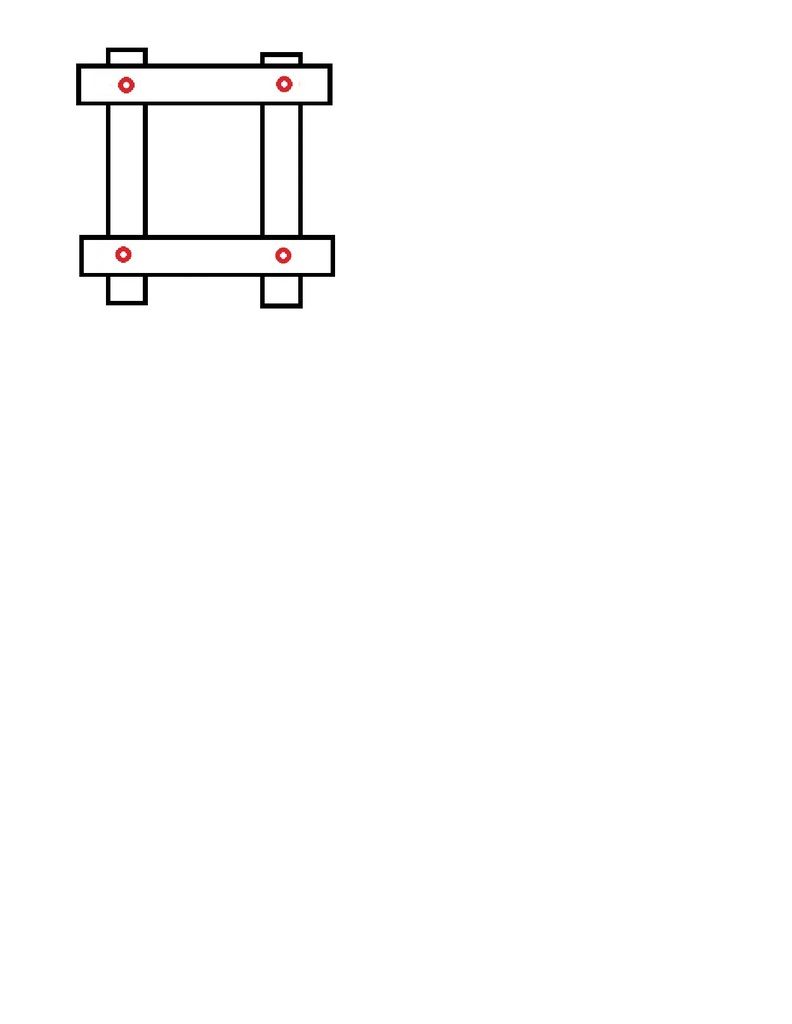

Any other ideas on how I should re-enforce the area I bolt the safe to under the floor... I thought cross sectioning the 2x6's kinda like the pic below or using about 4x4's but thought that was maybe a but much. I am not worried about the weight of the safe however as it is somewhat light... Probably a bit less that 500lbs loaded.

Thanks!

Win a FREE Membership!

Win a FREE Membership!