For many years I’ve used the LED strip lights for my reloading presses and have always been disappointed in the difficulty in providing enough light, especially when trying to see the powder charge in rifle cartridges. Another pain is when changing tool heads and moving the light strip out of the way.

Well there have been advances in LED technology in the past 5 years and when I built this spindle lamp for my mini mill I was blown away in how much light each bulb puts out.

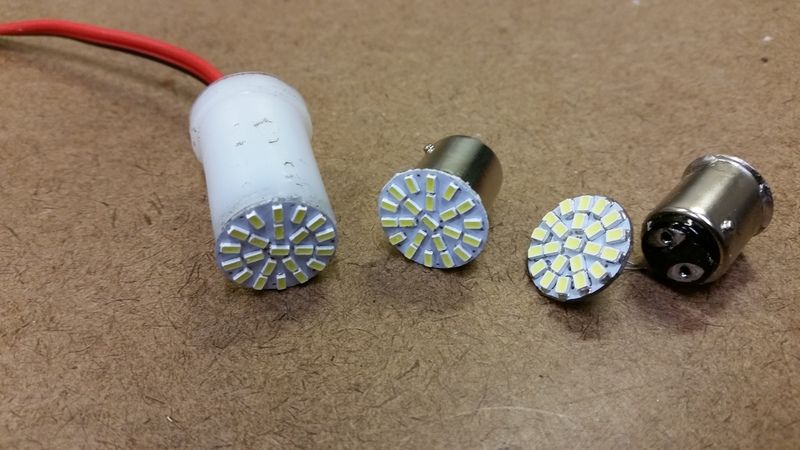

I bought a few different LEDs to play with

Time to explore options for replacing the LED strips with these new high output center mounted bulbs.

Some of the considerations are that the Dillon 650 has a larger center hole then the 550 and that the press ram does not enter this hole on the 650 as happens on the 550.

In order to have maximum output across the shell plate, the LED should protrude below the mounting hole.

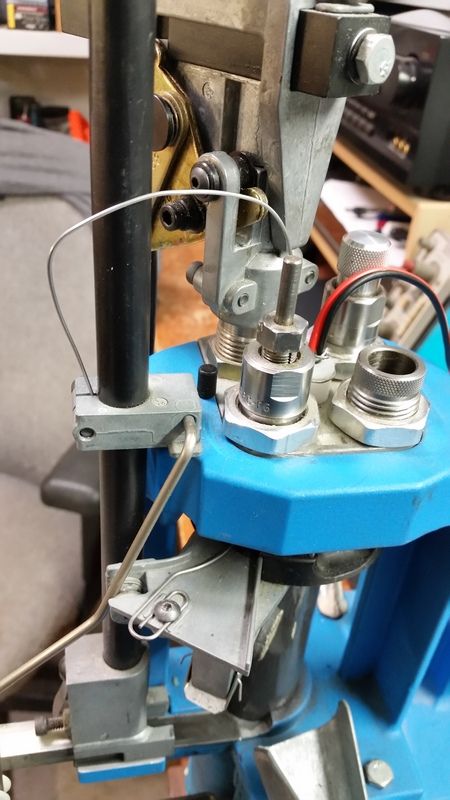

On the 650 that easy because there is adequate space between the tool head and ram when fully extended.

Disassemble the bulb from the base, turn and drill an insert to the proper depth and 650 light is good to go.

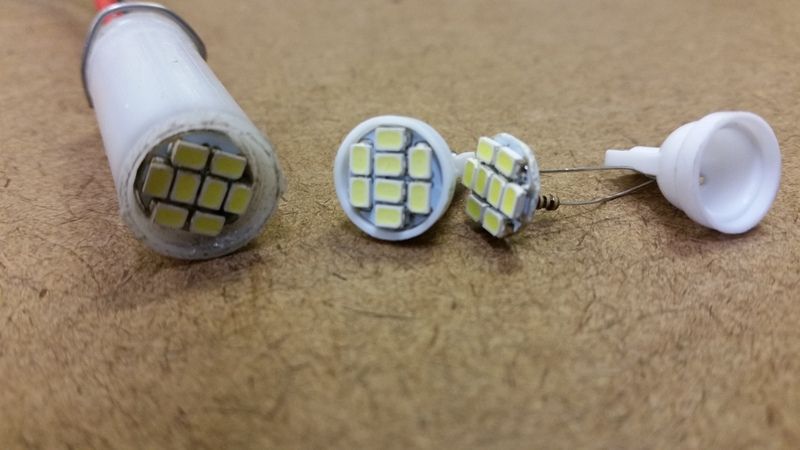

The 550 presented more of a challenge because the smaller hole diameter was too small for the larger LED array. It also normally would not allow the bulb to be mounted below the tool head surface because of the ram entering the tool head when fully extended.

Using a smaller diameter LED assembly was step one and after turning and drilling the mounting assembly it was game on. Also note that the LED is slightly recessed and the mounting ring lip actually contacts the ram, not the LED.

I came up with what I (tongue in cheek) refer to as the turtle head light. It is spring loaded so it extends well below the tool head and is pushed back up into it’s shell when the ram is extended

The ram pushing the bulb up

Here you can see the spring wire that pushes bulb below the tool head.

A variation on this uses a larger LED array.

And retracted

In a well lit room with 6 overhead florescent lights you can see how well the presses are illuminated with their new lights.

And one shot of my shop

Win a FREE Membership!

Win a FREE Membership!