|

Posted: 7/17/2016 6:32:54 PM EDT

I've wound up with a nice little dial-type depth gauge, and I thought "hey, I'll check some primers for seating depth!" Not so fast... Case heads don't just sit flat against the base because the base has this hole the dial gauge is screwed into.

I'm thinking that I could use my case gauges with the depth gauge, but then I'd have to measure how far below the top of the case gauge the case head is, which could be different for each individual round. Am I missing something? Is there an actual device/adapter/gadget that makes this work simply? For those who wonder why I'm thinking about measuring this at all, there's no anvil to bottom out on a Berdan primer. When I adjust the stop I added to my RCBS hand priming tool, I'd really like to know I got it right. |

|

|

|

[#1]

Why not just use your vernier caliper?

Most if not all have a built in depth gauge. |

|

|

|

[#2]

I want to use the depth gauge for precision, mainly. My dial caliper does have a depth function, but I want more detailed data than that tool will give me.

|

|

|

|

[#3]

The instrument is called a narrow rod depth micrometer.

Often not in production, what you can do is purchase a non-rotating blade depth micrometer and reduce the rod width. I think they come in 3mm width and about 1.2 thick. The blade does not rotate and can be customized by anyone with the skill and a grinder. |

|

|

|

[#4]

Quoted:

I want to use the depth gauge for precision, mainly. My dial caliper does have a depth function, but I want more detailed data than that tool will give me. View Quote I don't think you could get very precise measurements unless you deburred and trued every case head. Have you ever looked at some under magnification? They typically have all sorts of small burrs, dings and dents. That being said you could get reasonable measurements using a dail indicator in a fixed position and make a set up where you slide the casing under it squarely and read the difference between the case head and the primer. Motor |

|

|

|

[#5]

|

|

|

|

[#6]

IMO it's just easier to uniform the pockets and be done with it.

I firmly seat primers to the bottom of a clean pocket. My bench mounted RCBS priming tool creates plenty of leverage, yet allows me to feel the primer being inserted. If your primer pockets haven't been uniformed the depth will be different with every primer seated. Built up carbon contributes as well. I haven't switched to stainless steel pins, dawn dish washing detergent and lemonshine yet, but I feel this is the way to go for anyone just getting started. A clean as new primer pocket puts a smile on my face. I believe uniformed pockets add a measure of safety, especially in M1 Garands and M1-A's. I experienced a slam fire in a .308 M1 Garand (Camp Perry Regional Match around 1990) even though the safety was on when I closed the bolt. A little unsettling if you know what I mean. This happened using new Lake City NM brass and Federal 210M primers. I feel primer pocket uniforming offers very little accuracy advantage unless you're shooting Bench Rest or 1000 yards for record. It offers zero help in a semi-auto. It does allow the primer to be seated well below flush with each primer being the exact same depth. |

|

|

|

[#7]

|

|

|

|

[#8]

Quoted:

IMO it's just easier to uniform the pockets and be done with it. View Quote Me, too. There were a few times when burrs and concave case heads were giving faulty readings (while diagnosing chamber size, etc), but a quick deburring/skim cut of the head in my Wilson trimmer gave me a clean surface from which to measure. If your case heads are so concave that a uniformer will not give a uniform depth, get rid of that brass. |

|

|

|

[#9]

Quoted:

I firmly seat primers to the bottom of a clean pocket. My bench mounted RCBS bench priming tool creates plenty of leverage, yet allows me to feel the primer being inserted. View Quote The RCBS bench tool has a long enough lever arm to make seating easy while still providing incredible feel. You can easily feel the primer start, move in till the anvil touches, and then the final movement that seats the anvil against the primer pellet. I have tried multiple hand primers and the cam action used to drive the plunger has never felt as good as the RCBS bench tool. The only part i have ever needed to replace was the spring used to control the moving head. As usual free from RCBS. I even turned down 100 primer tubes from Blue to fit so I have a lot of 100 primer large and small tubes. Check the seater plug. They often have a small teat in the middle from the screqw machine used to make them. A few passes on a stone remove it. |

|

|

|

[#10]

Quoted:

There were a few times when burrs and concave case heads were giving faulty readings (while diagnosing chamber size, etc), but a quick deburring/skim cut of the head in my Wilson trimmer gave me a clean surface from which to measure. View Quote I've experienced and done the same. It helps. Danny |

|

|

|

[#12]

I have a fancy starrett or Brown and Sharpe depth gage and a dial gage on a magnetic base that goes to ten thousanths. and maybe even the half ten thousandth IIRC.

But I don't bother too often, I use my finger tip. |

|

|

|

[#14]

I've used my Starrett depth mic just to see how consistent my "feel" was with my Uni RCBS hand primer. If I recall all measured .003-.005 below flush, I called it good and never checked again.

As a machinist, the back side of a caliper won't be accurate unless you have a base mounted. |

|

|

|

[#15]

Quoted:

I've used my Starrett depth mic just to see how consistent my "feel" was with my Uni RCBS hand primer. If I recall all measured .003-.005 below flush, I called it good and never checked again. As a machinist, the back side of a caliper won't be accurate unless you have a base mounted. View Quote This is pretty much along the lines I was thinking. Especially with Berdan primers, my "feel" and the way I adjust the stop I installed on my RCBS hand primer isn't something I want to just "believe" I got right. And I knew the depth function of my caliper wasn't going to be really "right" unless I had more control than I felt I did. |

|

|

|

[#16]

Quoted:

Dial indicator bases are easy enough to make, but your back at the mercy of the dial indicator, and the how flush the base of the round is in the first place to indicator off of. http://cdn1.bigcommerce.com/n-yp39j5/4s9liwcv/products/103529/images/18262/imageRendering__79838.1414027057.1280.1280.jpg?c=2 Truth is, would just make a indicator base out of some 3/4" round stock and recess the bottom of it for a socket to accept the rim of the brass against to get readings. If I have some free time, will make one up to give you the idea, or just mail it to you since I have no use for one isntead. View Quote As I don't have the ability to make something like this myself, I really appreciate the offer. Let me triple check the diameter of the dial gauge stem in this device before you start cutting anything. I'm fairly confident that I'll be able to identify cases whose heads aren't flush/square/flat. And since I'm expecting to use this to verify that the depth stop in my hand priming tool is set properly, I won't be checking every single case, just a sample of them. Again, thanks for your offer! |

|

|

|

[#17]

GH, If you have a case gage or something else that will hold a case squarely all you need is a small flat area. Mount your dial indicator in something solid and slide your cases under it and simply read the difference between the head and the primer readings.

This way you don't need to keep tract of anything or have to deal with any irregularities. It's simple, fast and easy. You could probably use a thick piece of glass as your surface plate if you don't have anything else. You'll only be moving enough to go from the head to the primer in the horizontal plane so your surface plate does not have to be perfect. Motor |

|

|

|

[#18]

Quoted:

GH, If you have a case gage or something else that will hold a case squarely all you need is a small flat area. Mount your dial indicator in something solid and slide your cases under it and simply read the difference between the head and the primer readings. This way you don't need to keep tract of anything or have to deal with any irregularities. It's simple, fast and easy. You could probably use a thick piece of glass as your surface plate if you don't have anything else. You'll only be moving enough to go from the head to the primer in the horizontal plane so your surface plate does not have to be perfect. Motor View Quote I'd thought of using my case gages, but there's a problem: they have stepped base ends. One step for max headspace and another for minimum headspace. Making sure I had the base of the depth gauge on a solid level then measuring how far below the max step the actual head was were more complex than I wanted to try. It felt like trying to use my caliper's depth stem - too many chances for error to march in. |

|

|

|

[#19]

I understand. That is why I'm saying you use your indicator. Put the case in the gage on a flat surface. Slide it under the indicator tip. Then go from the head to the primer and read the difference.

Have the indicator moving just enough to get a reading. The indicator will need to be clamped in something solid above the flat surface. Do you understand what I'm trying to explain? Motor |

|

|

|

[#20]

This is what Motor is trying to describe.

" /> " />

It doesn't have to be magnetic or you can turn the magnet off to use it, but this is the set up you need. |

|

|

|

[#21]

Quoted:

I understand. That is why I'm saying you use your indicator. Put the case in the gage on a flat surface. Slide it under the indicator tip. Then go from the head to the primer and read the difference. Have the indicator moving just enough to get a reading. The indicator will need to be clamped in something solid above the flat surface. Do you understand what I'm trying to explain? Motor View Quote Yes, now I do. I was picturing using the depth gauge as it is, and the issues I actually had trying to get the base to settle on my case gauge. Using an indicator stand makes a whole lot more sense. Can you tell I'm no machinist?

|

|

|

|

[#22]

Quoted:

This is what Motor is trying to describe. http://<a href=http://i108.photobucket.com/albums/n26/PirateBill666/Magbase_lg.jpg</a>" /> It doesn't have to be magnetic or you can turn the magnet off to use it, but this is the set up you need. View Quote Yep, I get it now! |

|

|

|

[#25]

|

|

|

|

[#26]

Thanks, Molon, but squaring case heads is beyond me for now. I'm going to stick with my Ballistic Tools GO-NO GO primer pocket gages for round/out of round assessments. But those pesky Berdan primers taunt me. "Are you sure you seated me deep enough? If you didn't, I'll either slam fire or not go off at all." I also figure this will help me verify my LnL AP's priming system is doing its job properly - and consistently.

Is that a tire tread depth gauge? |

|

|

|

[#27]

|

|

|

|

[#28]

When I was looking for generic depth gauges, I saw tons of tire tread gauges, but they all seemed to have wide probes, not like the one you're using. If I'd seen one with the small diameter probe, I might have gone in a different direction...

|

|

|

|

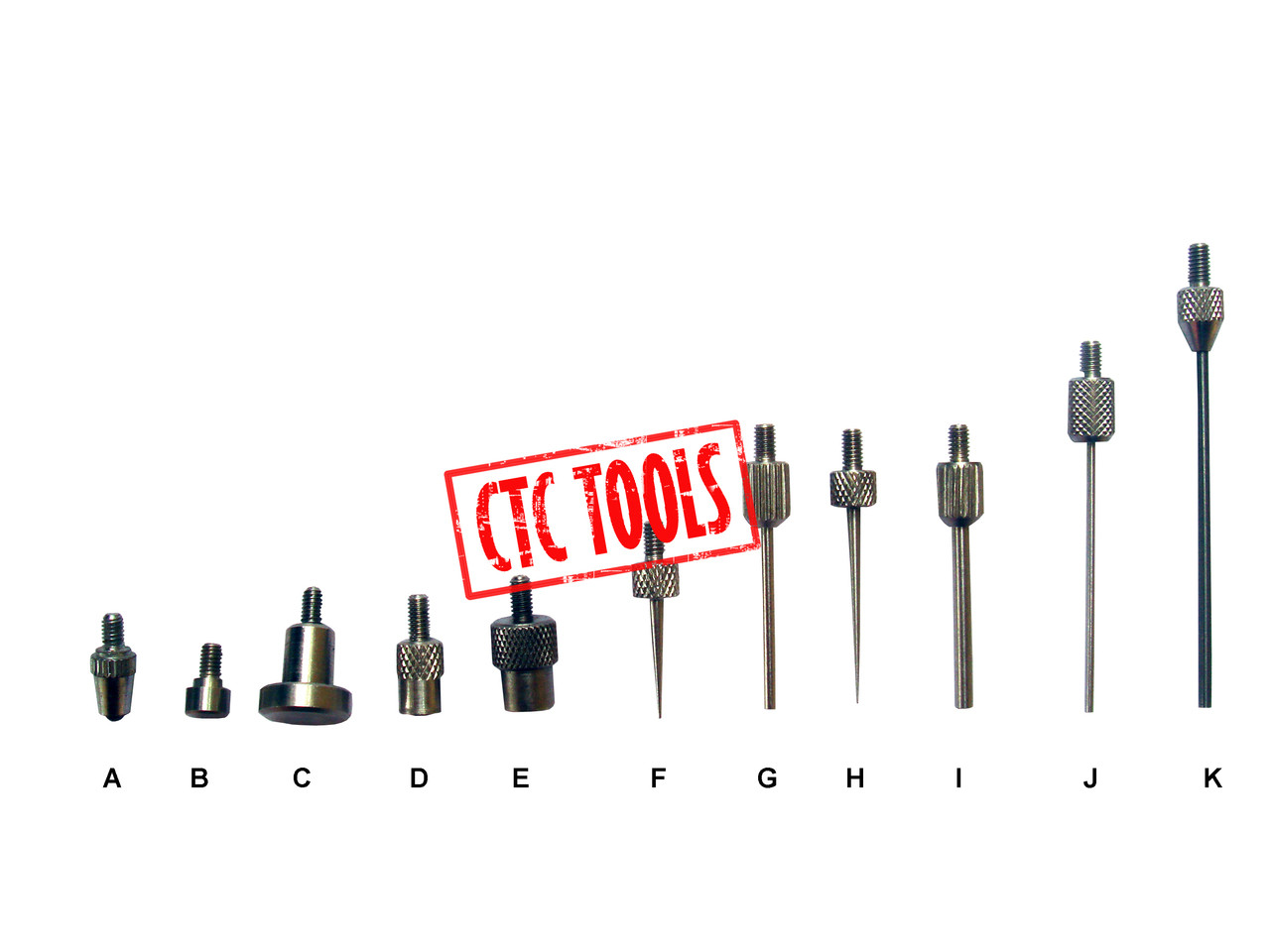

[#29]

Digging the concept some what. The down side, you have to use thumb pressure on the wheel, and need to make sure that you are still square against the tools shoulders at the same time as you are moving the case around on the tool (seems like the slow way). Or, with a J tip in the dial indicator

Off set the recess rim channel in the adapter with a small through channel a thousands over for just the J tip on a dial indicator to protrude through to read the edge of the berdan primers in the 7.63x39 case instead. Hence as you run the case tight against the recces bearing surface and turn it, will give you the outer circumference reading depths of the primer edge in the pocket all the way around since the rod in the dial gauge is spring loaded and less to fight and larger square surface to hold the case to instead. A berdan primer is 5.5mm,and depending the OD of the needle probe, would tell me what I need to off set the adapter in the lathe chuck to off set the rim recess channel in the gauge adapter, for the needle contact point to pick up just the outer edge circumference of the primer instead. http://www.mscdirect.com/product/details/06444491 |

|

|

|

[#30]

I still don't understand the OP's objective.

Why measure at all? Use time/effort to apply a primer pocket uniformer and KNOW the depth is uniform. |

|

|

|

[#31]

|

|

|

|

[#32]

Quoted:

Op is seating Berdan primers. Where do you get a uniformer for them? View Quote View All Quotes View All Quotes Quoted:

Quoted:

I still don't understand the OP's objective. Why measure at all? Use time/effort to apply a primer pocket uniformer and KNOW the depth is uniform. Op is seating Berdan primers. Where do you get a uniformer for them? Have one ground. It will last you forever. Diameter, depth, center relief to clear anvil. |

|

|

|

[#33]

Quoted:

Have one ground. It will last you forever. Diameter, depth, center relief to clear anvil. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Quoted:

I still don't understand the OP's objective. Why measure at all? Use time/effort to apply a primer pocket uniformer and KNOW the depth is uniform. Op is seating Berdan primers. Where do you get a uniformer for them? Have one ground. It will last you forever. Diameter, depth, center relief to clear anvil. Well there's a problem with that. While the diameter of available Berdan primers is all 0.217", 7.62x39 uses one pocket depth, while 7.62x54R, and (maybe) European .30-06/308-class cases use a different depth. So I'd need to special order TWO custom made cutting tools. Which means I'd need to do the precise specs, drawings, and tolerances for two unique tools - way beyond my current capability. On the other hand, I have a hand priming tool that is already set up with a deapth stop, and all I really want to do is to verify that my stop is set correctly for Berdan priming. That's one specific measurement with a nice, neat tolerance, no matter which kind of Berdan primer I'm using. I'd sure love a well made Berdan primer pocket cleaner tool, and by extension a Berdan primer pocket uniforming tool, but right now both are very much theoretical tools at the moment... |

|

|

|

[#34]

Quoted:

Op is seating Berdan primers. Where do you get a uniformer for them? View Quote View All Quotes View All Quotes Quoted:

Quoted:

I still don't understand the OP's objective. Why measure at all? Use time/effort to apply a primer pocket uniformer and KNOW the depth is uniform. Op is seating Berdan primers. Where do you get a uniformer for them? DOH! Somewhere in this thread that minor little fact just snuck in, eh? LOL! Given that little tidbit of additional information, I have a solution - use boxer primed brass, instead. |

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.