The Dillon manual says that "the proper amount of swage is done by trial and error. Not enough swage and the primers won't seat fully. Too much swage will stress the unit, possibly bending the locator rod." I have not even come close to "bending the locator rod", however, I believe that when I'm using too heavy of an adjustment that the bottoms of primer pockets can be deformed. So tell me how you adjust your Super Swager and what clues you use to indicate that it is adjusted too heavy or too light?

Currently I only swage 223/5.56 cases so my discussion is only about them. The Super Swager is deforming the bottom of some of my 223/5.56 primer pockets and I notice this when I uniform the primer pocket (see Pictures 1 & 2). I figure this deformation is caused by the locator rod end being too small and that it doesn't exactly center in the pocket. The primer pocket is about 0.175" in diameter and the end of the locator rod is much smaller at about 0.140". In my opinion this is not enough support (what I call a footprint). The rod doesn't center in the pocket because the case neck diameter is about 0.223" and the shaft of the rod is smaller at about 0.210" (the rod falls down slightly and only supports the lower part of the primer pocket). I purchased another locator rod so I could experiment with one by grind down its end to make a bigger footprint (see Picture 3). I increased the footprint from about 0.140" to about 0.165". This is still not as large as the primer pocket at 0.175", but it provides about 39% more footprint. I think the extra footprint might even help repair some of the pocket bottoms I have already damaged and I'm sure this bigger footprint won't damage my cases as much as the stock Dillon rod does. I saw evidence of this when I tested some of my scrap cases (I do not crush my scrap cases which allows me to use them as test cases). I have not found any problems inserting the case on the rod even though there is less of a funneling slope.

My Super Swager handle can "stick" from a little to a lot depending on how heavy I push the handle. If I use too heavy of an adjustment (unintentionally), I have to give the handle a good smack up before it will release the case. Adding grease or oil helps reduce the sticking but it isn't long before the sticking is back. Has anyone else had this "sticking" problem?

Another problem I found is that when a swage is done then any burrs on the inside of the primer hole are flattened out (see Picture 4). I just recently purchased a flash hole deburring tool (RCBS .22 Caliber 88145). Unfortunately, my brass has already been swaged. It would have been best if I had deburred the flash hole after receiving once fired brass. I'll do that the next time I purchase once fired brass.

Picture 1 - This picture shows that the uniform bit only touched one side of the pocket (shiny part at bottom of picture). I believe this is due to the Super Swager deforming the pocket. It is not due to the uniformer going in crooked as I have checked that.

" />

Picture 2 - If the pocket is not deformed then the uniform bit will do its thing all the way around the pocket as shown by this picture. Well actually this case was deformed a little when the primer hole was punched so the center of the primer pocket was not uniformed. By the way, I use the uniform bit on each and every case mainly to remove the residue along the edge of the pocket after pin cleaning. I don't do a full uniform on my cases as I'm afraid it might make the bottom of the primer pocket too thin.

" />

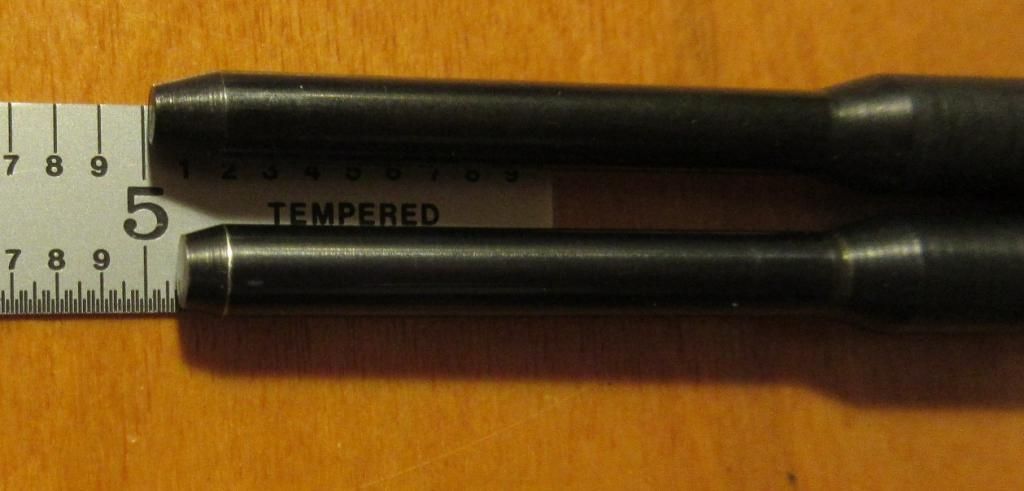

Picture 3 - This picture shows that my 2nd locator rod has been ground down giving a bigger footprint inside the case. I didn't want to grind down too much as the ramp in the middle of the rod is very close to the case neck. I have to be careful as the ramp could flair out the edge of the case neck. I used a bench grinder and I think I did a fair job making the edge flat enough.

" />

Picture 4 - This picture shows what happens when the Super Swager is used before removing primer burrs (the burrs may flatten out blocking the primer hole).

" />

Win a FREE Membership!

Win a FREE Membership!