|

Posted: 2/4/2012 1:06:17 AM EDT

[Last Edit: Eight_Ring]

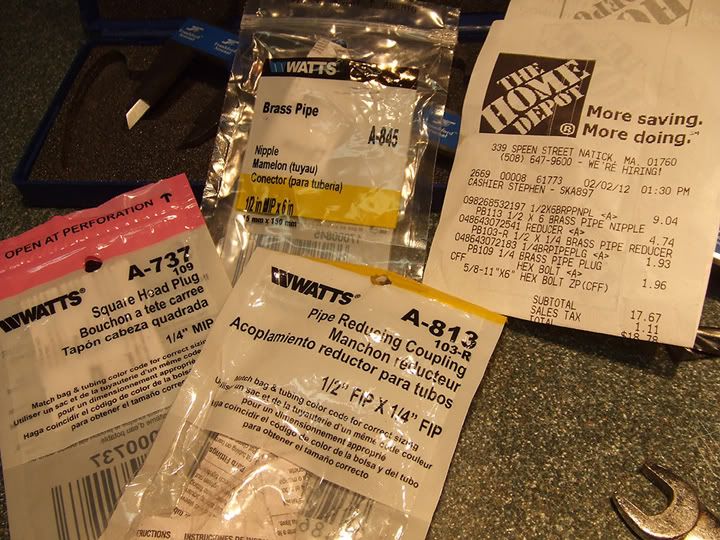

I saw a pretty interesting Youtube video of a guy in Australia decapping Berdan cases using just a piece of pipe, a big hammer, and a bucket of water (LINK). Looked pretty slick, so I thought I'd have a go at it myself. His decapper was a piece of brass pipe with a washer brazed onto the end of it––but I don't have any welding tools. I figured I could make one up––and figured out a way to build my own decapper out of stuff that could be had readily at any Home Depot.

NOTE: The square plug that threads into the bottom of the base is just there to provide additional support to the bronze flange. After you screw the square plug into the bottom of the base, drill through the bottom and/or cut the square part off with a hacksaw, so the water (and the loose primer) can be ejected out through the bottom.

Total cost for the deluxe version was about $27––including bronze bushings and a couple optional galvanized fittings. You maybe might just want to go with iron pipe and fittings (or hit the salvage yard), because brass is pretty expensive––a 6" piece of threaded 1/2 inch w as $9––daaayum. I used a bronze bushing to center the cartridge case (7.5 Swiss/7.5 French MAS/etc.) in the 1/2" tube and also to support the case head.

The hole in the bushing is the perfect size for the primer.

I found the real key to hydraulic decapping is hammer mass + speed , but also to swing the hammer like you have a pair. The 3 lb sledge offered pretty good consistency after I got comfortable swinging it hard.

The ram is just a 6" Zinc bolt with the threads cut off. To protect the neck of the brass pipe from overtravel I fitted the ram with a piece of 1/2" radiator hose I had left over from my stainless tumbler build. I actually bought the bronze inserts at ACE Hardware. They have them in the Hardware aisle. The size of your particular fitting would depend on the caliber you are looking to decap I guess. I am decapping 7.5 Swiss, 7.5 French (MAS), .6.5 Swede, 308, and 30.06––and I went with a 1/2 X 5/8 X 1 1/8 sleeve. I had to chuck it up in a drill and dress it down a bit with a file so it would press-fit into the brass pipe. To support the case-head I used a 1/4 X 3/8 X 15/32 bronze flange. It's about perfect, it self-centers––and fits so well the pipe doesn't even leak; it is pretty much water-tight until you set the ram into the pipe and strike it. Anyhow––I hope somebody finds this useful. Good luck. |

|

|

|

|

I would love to see that in action

Awesome! |

|

|

|

|

That seems a good way around the decapping problem, does it work well?

|

|

|

|

|

Do you think it could be rigged up to an electric type set up ? Maybe use some sort of solenoid operated ram?

Or, even a manually leveraged fulcrum with enough mechanical advantage that it would do the job, so you would have to use the hammer.. |

|

|

Don't go ninj'in nobody that don't need ninj'in

|

|

wow! great write up and pictures. This is worth toggling to keep it out of the archives

|

|

|

"Bullets change governments far surer than votes.." - Lord of War 2005

"The trouble with socialism is that you eventually run out of other people's money" – Margaret Thatcher |

|

Originally Posted By pavlovwolf:

Do you think it could be rigged up to an electric type set up ? Maybe use some sort of solenoid operated ram? Or, even a manually leveraged fulcrum with enough mechanical advantage that it would do the job, so you would have to use the hammer.. Brilliant minds think alike, Pavlovwolf––that is EXACTLY where I see the design going next. All I need is the chassis––and the plunger/piston would need some rubber O-ring inserts (lol). Maybe thread the base of the unit into a much larger pipe, so you are generating high pressure with more volume/shorter stroke? Have at it and let us know what you come up with––the hammer absolutely is the weak link in the process. TZapp––I'll try to get a video up, but click on the video link for the Aussie guy decapping and it's pretty much the same thing, basically––except your crotch doesn't get (as) wet. (lol). OK, I just re-watched the video––I have to hit the ram with my hammer about twice as hard as he does––because he is compressing the stack of water from a 1" pipe with a 1" ram whereas I used 1/2" pipe 1/2" ram––so to compensate I used a heavier hammer and more energy behind it (story of my life/lol). I'd guess 1" is the way to go with the chamber if you have access to the materials. |

|

|

|

|

Global Warming Hoax Skeptic before it was cool

|

The question I have is where does the water go?

Is there a hole in the wood block for it to drain out of? Great pics and good thread. I am going to set the toggle to keep this thread out of the archives. When this thread slips into the back pages, just click on My Topics and this thread will come up for you so you can post a link to it. Instead of searching for you thread on the back pages of the forum. Also Team members can do a search for it. Well done.

|

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

|

That is agreat idea, but where do you get the berdan primers?

|

|

|

|

|

This is the method I copied, using a press is a bit quicker but you need either a mobile press to take outside or an area you can dump water all over and it won't matter.

http://www.youtube.com/watch?v=ZQNDgjcgofY Skip to about 8:15 if you jut wanna skip the tech part and see the press in action. I tried a block of wood with the hole with a hammer and punch this summer but I destroyed every 5th case neck or so

|

|

|

|

|

OP, being as you look to have compression fittings there, I have perhaps an idea.

If you were to make a chamber sized cavity that fit the case pretty well like a die, or more exactly, like a cartridge gauge, could you not use a much higher pressure hydraulic hose, say for a tractor or industrial machine of greater size, rather than the small copper that you have. Something that could hold up to greater pressure ? That way, you could design a system where you could take the fitting for various calibers and insert it into a master block so you could change them on the fly if you had more than one caliber. Also, as for using the higher pressure lines, that would possibly allow you to use some sort of automation that would increase the pressure until the primer popped out. Perhaps maybe you could use a hydraulic jack , where you modify the jacking mechanism to do the work for you rather than swinging the hammer. From there, using an air compressor or the like to pump the jack handle portion would allow you to essentially insert a case, close it off, and hit a button that would actuate the jack, thereby using the hydraulic pressure from the piston in it to pressurize the fluid and push the primer out. Just a thought. If it works, it could be miniaturized down to a bottle jack sized kit. Even if you didn't want to go electric to actuate it, you could easily add a foot pump. Hey, if you sell it, I get a small cut. lol |

|

|

Don't go ninj'in nobody that don't need ninj'in

|

|

It looks to me like a sizing die that you could seal the top on with no decapping stem at all would work, just fill the case with water and run it trough the die, as the case is sized the water is compressed and the primer will be pushed out, finding a way to seal the top of the die so it will pressure up may be difficult.

|

|

|

|

|

Why am I having a duh moment right now? lol

|

|

|

Don't go ninj'in nobody that don't need ninj'in

|

|

Originally Posted By dryflash3:

The question I have is where does the water go? Is there a hole in the wood block for it to drain out of? Great pics and good thread. I am going to set the toggle to keep this thread out of the archives. When this thread slips into the back pages, just click on My Topics and this thread will come up for you so you can post a link to it. Instead of searching for you thread on the back pages of the forum. Also Team members can do a search for it. Well done. Dryflash–– I did in fact drill a hole in the block––straight down 6 or 7 inches, and then angling at a 45 degree angle toward the side facing away from the operator––you can see the hole low in front in picture #10. Thanks for the toggle. |

|

|

|

|

Originally Posted By pavlovwolf:

OP, being as you look to have compression fittings there, I have perhaps an idea. If you were to make a chamber sized cavity that fit the case pretty well like a die, or more exactly, like a cartridge gauge, could you not use a much higher pressure hydraulic hose, say for a tractor or industrial machine of greater size, rather than the small copper that you have. Something that could hold up to greater pressure ? That way, you could design a system where you could take the fitting for various calibers and insert it into a master block so you could change them on the fly if you had more than one caliber. Also, as for using the higher pressure lines, that would possibly allow you to use some sort of automation that would increase the pressure until the primer popped out. Perhaps maybe you could use a hydraulic jack , where you modify the jacking mechanism to do the work for you rather than swinging the hammer. From there, using an air compressor or the like to pump the jack handle portion would allow you to essentially insert a case, close it off, and hit a button that would actuate the jack, thereby using the hydraulic pressure from the piston in it to pressurize the fluid and push the primer out. Just a thought. If it works, it could be miniaturized down to a bottle jack sized kit. Even if you didn't want to go electric to actuate it, you could easily add a foot pump. Hey, if you sell it, I get a small cut. lol A Haskle Pump is what your thinking about, it's an air driven hydraulic pump that works with oil or water, you can get them for high pressure/low volume or low volume/high pressure and a range of in between. We use them to hydraulic pressure test oil tools once they are assembled to make sure nothing leaks, the one we use is fairly low volume but once the tool is full of water it will pump to 6K psi in only a few seconds. This one is super overkill but is priced very low and appears to be in great condition, they can be rebuilt easily and will last for ever. http://www.ebay.com/itm/Haskel-DXHW602-Air-Driven-Fluid-Pump-Oil-Water-75-000-PSI-w125psi-ofair-/200707585955?pt=LH_DefaultDomain_0&hash=item2ebb1ab7a3#ht_7788wt_1185 |

|

|

|

|

Yep.

I couldn't remember what they were called. When I was the service writer/Tire salesman/parts salesman/ oh so many other things person, at a local tire store and garage one of the things we did was service tractors. Part of that job was making hydraulic hoses. We had to pressure test them before we sent them out, or installed them. That's what we used. Thanks |

|

|

Don't go ninj'in nobody that don't need ninj'in

|

|

Global Warming Hoax Skeptic before it was cool

|

Originally Posted By Eight_Ring: Originally Posted By dryflash3: The question I have is where does the water go? Is there a hole in the wood block for it to drain out of? Great pics and good thread. I am going to set the toggle to keep this thread out of the archives. When this thread slips into the back pages, just click on My Topics and this thread will come up for you so you can post a link to it. Instead of searching for you thread on the back pages of the forum. Also Team members can do a search for it. Well done. Dryflash–– I did in fact drill a hole in the block––straight down 6 or 7 inches, and then angling at a 45 degree angle toward the side facing away from the operator––you can see the hole low in front in picture #10. Thanks for the toggle. Ok, I see the hole now. You earned the toggle with this thread.

|

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

|

OK––here is a technical challenge.

The small 1/2" diameter pipe I used relies on moving a 3 lb hammer semi-fast to decap Berdan. Not a promble, I'm a biggish guy and I enjoy swinging a hammer. But can anybody come up with an easier way––by (for instance) dropping/securing/threading the bottom half of what I made into a larger volume pipe (1" for example) and using a larger diameter ram, so you are moving more water/leveraging more water weight when you strike it? Try to make the source for your parts a national hardware chain (ACE, Robinson, Sears, etc) or Home Depot, Lowes etc.. I'm going to work on a mist curtain for the top of the pipe, and I'll post pics when I work it out. I'm thinking a tuna can set puside down with a hole in the center for the ram. |

|

|

|

|

You might be better off with a smaller diameter piston/cylinder for higher pressure rather than increasing the flow, actually. You only need to move enough water to push the primer out, plus leakage.

To do that, maybe put a fitting on top of the brass pipe that necks down for a smaller rod. Maybe a threaded pipe to solder copper fitting would work. |

|

|

|

|

Why?

Just why? |

|

|

|

|

Originally Posted By Still_learning:

Why? Just why? Are you asking why bother with berdan primed cases? |

|

|

|

|

Originally Posted By TZapp:

Originally Posted By Still_learning:

Why? Just why? Are you asking why bother with berdan primed cases? I'm guessing his familiarity with Berdan is limited to the AK. Or maybe he doesn't mind paying long money for boxer brass in obscure calibers. ETA: I shot some video of working at hydraulic decapping today. I'll post it if anybody wants to see it. |

|

|

|

|

Originally Posted By TZapp:

Are you asking why bother with berdan primed cases? Yes, pretty much, that's the question. Originally Posted By Eight_Ring:

I'm guessing his familiarity with Berdan is limited to the AK. Or maybe he doesn't mind paying long money for boxer brass in obscure calibers. I've never had or used an AK. In my world, I consider the availability of ammunition and reloading components before I buy the rifle. I was going to buy an Enfield but it was going to be a Ishipore Enfield chambered in 308, not 303. I guess if you really have to have a rifle in a particular, obscure cartridge,... |

|

|

|

|

There is tons of 7.62x51 berdan brass out there. Most people just chunk it or give it away free.If you can decap it and prime it, you have really cheap brass. Some of it is really good quality too.

|

|

|

Don't go ninj'in nobody that don't need ninj'in

|

|

Global Warming Hoax Skeptic before it was cool

|

|

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

|

Where/when did you buy the primers?

|

|

|

|

|

Originally Posted By Still_learning:

Originally Posted By TZapp:

Are you asking why bother with berdan primed cases? Yes, pretty much, that's the question. Originally Posted By Eight_Ring:

I'm guessing his familiarity with Berdan is limited to the AK. Or maybe he doesn't mind paying long money for boxer brass in obscure calibers. I've never had or used an AK. In my world, I consider the availability of ammunition and reloading components before I buy the rifle. I was going to buy an Enfield but it was going to be a Ishipore Enfield chambered in 308, not 303. I guess if you really have to have a rifle in a particular, obscure cartridge,... If you can do it with proficiency it opens up a whole new source of brass. In hard times it would put you ahead of the curve. There are lots of people who do things that are not neccessary in todays world, but todays world can change with the blink of an eye. |

|

|

|

|

Originally Posted By Still_learning:

Where/when did you buy the primers? Dag Ammo. Last week. |

|

|

|

|

Global Warming Hoax Skeptic before it was cool

|

|

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

|

Video of my home-built in action:

Manual Link: Some lessons learned: I had originally thought that in order to decap with my setup I needed to really put the chinga to it with a big old 3 pound sledge–– at first I tried to rush the process and smack the ram before it settled too much, thinking I was increasing pressure on the primer––and that is just wrong. A poster on another board (Boris @ Northeastshooters.com) had noticed that by allowing the ram to settle into the tube the the halfway point that the compression effect was somehow amplified. And it absolutely is. You'll see in the vid that I am using a regular old common hammer and occasionally landing a glancing blow, and still the cartridge case decaps––so kudos to Boris. I also noticed that my decapping got a lot more consistent after the wood of the stump had compressed––so there was no "give" to it. It makes a big difference, work on as hard a surface as you can, so all the force of your hammerstrike goes into the decapping process. Also––in constructing my decapping tube you will see a rubber o-ring in the pictures. Disregard the o-ring. I ended up just smearing a dab of Permatex gasket compound around the neck of the bronze flange (under the case head) and it worked like gangbusters. Anyhow––that's it––happy decapping

|

|

|

|

|

Excellent work! I hope to join you soon as one of the few hydraulic decappers of berdan!

|

|

|

Want to meet members near you or attend local events? Check out the Hometown Board!

"The only way I'd climb that wall of text is if Summer Glau was holding a beer in her left hand and a steak in her right at the summit." - Slavac |

|

Great write up!

Just before you started, I posted a question about Berdan de-capping in "the land of Berdan cases" - the Europe hometown forum: http://www.ar15.com/forums/t_8_49/476534_Berdan_primed_brass___how_is_it_reloaded_in_Europe_.html According to the only responder, the Europeans either use the RCBS tool or some sort of hydraulic method (details not specified). In that thread, I posed the following link to a guy doing hydraulic decapping in England: http://davecushman.net/hydraulic.html One thought: that thread seems to suggest adding "soap" to the water - maybe to reduce the water's surface tension? I will add more later at my so-far unsuccsesful attempts to de-cap (hint: black iron tubing tends to have a "seam" and is not ideal). |

|

|

|

|

Great info. Thanks for posting. I did a box full of Berdan primed brass with the RCBS tool over the last few days and I started searching for a quicker way and came across your thread. My only complaint with the RCBS tool is that I keep breaking the pin. I did get almost a whole box before I broke the last one but in my attempts to be careful it really slowed down the process.

I stopped by Home Depot and Ace today and got all the parts for your invention but I have one question. I couldn't find a zinc bolt that was a tight fit for my 1/2 pipe. What is the diameter of your bolt? I notice some tape on the end of one. Was that to tighten the fit? What type tape did you use? I've almost got it together and am looking forward to giving it a try. Thanks again for your helpful post. JS |

|

|

NRA Life Member

|

|

Global Warming Hoax Skeptic before it was cool

|

If your breaking the pin on the RCBS decapper, you have it adjusted too deep.

It's hitting the anvil of the case. After about 5k decapped with my used RCBS decapper I broke the pin. A call to RCBS got me two more pins.

|

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

|

Originally Posted By osucowboy8:

Great info. Thanks for posting. I did a box full of Berdan primed brass with the RCBS tool over the last few days and I started searching for a quicker way and came across your thread. My only complaint with the RCBS tool is that I keep breaking the pin. I did get almost a whole box before I broke the last one but in my attempts to be careful it really slowed down the process. I stopped by Home Depot and Ace today and got all the parts for your invention but I have one question. I couldn't find a zinc bolt that was a tight fit for my 1/2 pipe. What is the diameter of your bolt? I notice some tape on the end of one. Was that to tighten the fit? What type tape did you use? I've almost got it together and am looking forward to giving it a try. Thanks again for your helpful post. JS View Quote JS-- The shank on my bolt mics at .606--if i recall correctly it was a 6 1/4 bolt and I just sawed off the threads. I might've sanded it down a little, just to smooth the rough zinc testure, enough to get it to fit. The black ring at the top of the ram is a piece of rubber hose, to act as a bumper in case of a late strike. The teflon tape shown in one of the pictures turned out to be totally unnecessary. I also got along just fine with a regular hammer, and it swings faster, though the mallet delivers more force. Good to hear somebody is having a go at hydraulic depriming. I kinda like it--though it gets cold in the winter months, just use a bucket of warm water (lol). If you have to deal with removing a primer crimp, Dryflash has shown picsof a modded up Lee chamfering tool--mill off the end so it doesn't make contact with the berdan anvil, and then ream away the crimp. All the best. |

|

|

One if by land, and two if by sea; and I on the opposite shore will be.....

|

|

Are you swagging the berdan pockets to convert to boxer after you remove the primer?

|

|

|

Kill all but Nine...

VOTE FREEDOM FIRST! |

|

Originally Posted By Weber:

Are you swagging the berdan pockets to convert to boxer after you remove the primer? View Quote No, we're loading them with Berdan primers. |

|

|

NRA Life Member

|

|

Global Warming Hoax Skeptic before it was cool

|

Originally Posted By Eight_Ring: JS-- The shank on my bolt mics at .606--if i recall correctly it was a 6 1/4 bolt and I just sawed off the threads. I might've sanded it down a little, just to smooth the rough zinc testure, enough to get it to fit. The black ring at the top of the ram is a piece of rubber hose, to act as a bumper in case of a late strike. The teflon tape shown in one of the pictures turned out to be totally unnecessary. I also got along just fine with a regular hammer, and it swings faster, though the mallet delivers more force. Good to hear somebody is having a go at hydraulic depriming. I kinda like it--though it gets cold in the winter months, just use a bucket of warm water (lol). If you have to deal with removing a primer crimp, Dryflash has shown pics of a modded up Lee chamfering tool--mill off the end so it doesn't make contact with the berdan anvil, and then ream away the crimp. No I used a round Ball end mill, 1/4 shank. All the best. View Quote View All Quotes View All Quotes Originally Posted By Eight_Ring: Originally Posted By osucowboy8: Great info. Thanks for posting. I did a box full of Berdan primed brass with the RCBS tool over the last few days and I started searching for a quicker way and came across your thread. My only complaint with the RCBS tool is that I keep breaking the pin. I did get almost a whole box before I broke the last one but in my attempts to be careful it really slowed down the process. I stopped by Home Depot and Ace today and got all the parts for your invention but I have one question. I couldn't find a zinc bolt that was a tight fit for my 1/2 pipe. What is the diameter of your bolt? I notice some tape on the end of one. Was that to tighten the fit? What type tape did you use? I've almost got it together and am looking forward to giving it a try. Thanks again for your helpful post. JS JS-- The shank on my bolt mics at .606--if i recall correctly it was a 6 1/4 bolt and I just sawed off the threads. I might've sanded it down a little, just to smooth the rough zinc testure, enough to get it to fit. The black ring at the top of the ram is a piece of rubber hose, to act as a bumper in case of a late strike. The teflon tape shown in one of the pictures turned out to be totally unnecessary. I also got along just fine with a regular hammer, and it swings faster, though the mallet delivers more force. Good to hear somebody is having a go at hydraulic depriming. I kinda like it--though it gets cold in the winter months, just use a bucket of warm water (lol). If you have to deal with removing a primer crimp, Dryflash has shown pics of a modded up Lee chamfering tool--mill off the end so it doesn't make contact with the berdan anvil, and then ream away the crimp. No I used a round Ball end mill, 1/4 shank. All the best. |

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

|

Global Warming Hoax Skeptic before it was cool

|

Originally Posted By Weber: Are you swagging the berdan pockets to convert to boxer after you remove the primer? View Quote Large Berdan primer pockets are a larger diameter than a Boxer primer. Which means if a Boxer primer was inserted in a "modified" Bedan primer pocket, it will fall out. Some folks glue them in, but not something I would do.

|

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

|

Originally Posted By dryflash3:

Large Berdan primer pockets are a larger diameter than a Boxer primer. Which means if a Boxer primer was inserted in a "modified" Bedan primer pocket, it will fall out. Some folks glue them in, but not something I would do.  View Quote View All Quotes View All Quotes Originally Posted By dryflash3:

Originally Posted By Weber:

Are you swagging the berdan pockets to convert to boxer after you remove the primer? Large Berdan primer pockets are a larger diameter than a Boxer primer. Which means if a Boxer primer was inserted in a "modified" Bedan primer pocket, it will fall out. Some folks glue them in, but not something I would do.  I seen a post on another forum of a guy drilling them out and the swaging the old primer, and using that to hold the new boxer type in place. Ever tried that? |

|

|

Kill all but Nine...

VOTE FREEDOM FIRST! |

|

Global Warming Hoax Skeptic before it was cool

|

|

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

|

I'd like to revive this thread! Great idea for someone that doesn't have a machine shop to create a usable decapper. I've tried to locate the parts from Ace on-line but haven't had any success. Does anyone have item numbers or a good nomenclature for the sleeve and bushing?

|

|

|

|

|

Global Warming Hoax Skeptic before it was cool

|

I would recommend decapping with a nail set if you don't want to buy the RCBS decapper. Wet decapping is a mess. Read about it here, |

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

|

Thanks for brining this one to the top again.

|

|

|

|

|

Global Warming Hoax Skeptic before it was cool

|

Originally Posted By Dominion21: Thanks for brining this one to the top again. View Quote Note that the last 4 or 5 pages of this forum are where you find the threads AeroE and I have saved from the archives. We call it setting the archive toggle. Plain English=this thread will not go into the archives. The mods see a special icon next to the thread title, that isn't visible to Members or Team Members. So threads are just waiting there ready to come to live again as needed. Like this one. If someone thinks a new thread that's running needs an archive toggle, contact me via IM and I can set the archive toggle. I try to set the archive toggle on threads that I think are of interest, like the new 5 and 7 station RCBS press threads. When I do, I always post in the thread that the toggle is set for that thread. |

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.