|

Posted: 6/5/2011 3:58:14 PM EDT

[Last Edit: BIGGDAWG]

I thought i would post some pictures up of my build. After seeing all the shiny brass guys are posting I decided I wanted to

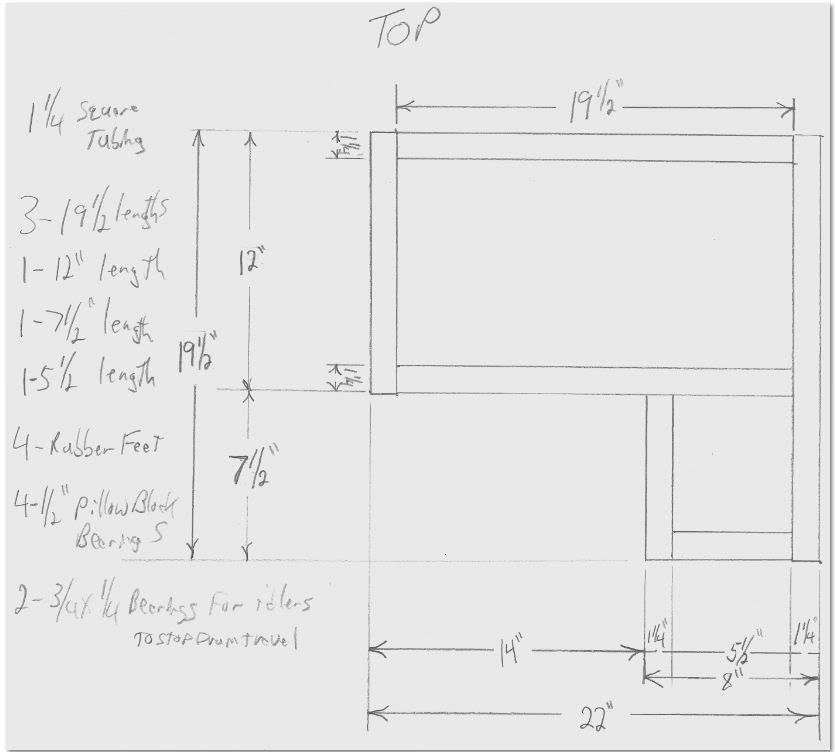

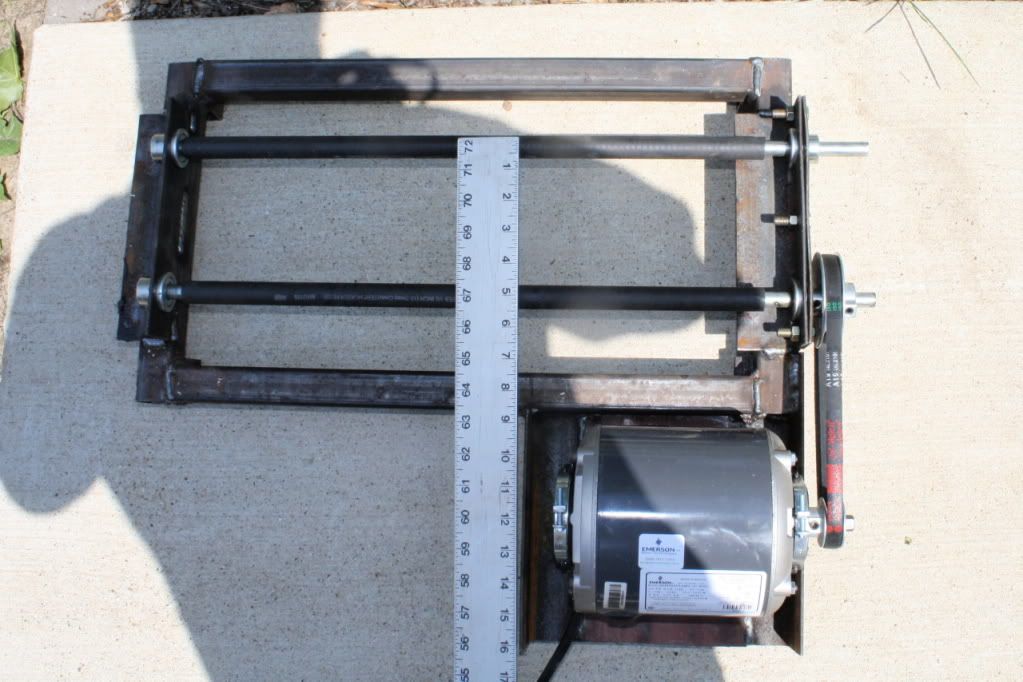

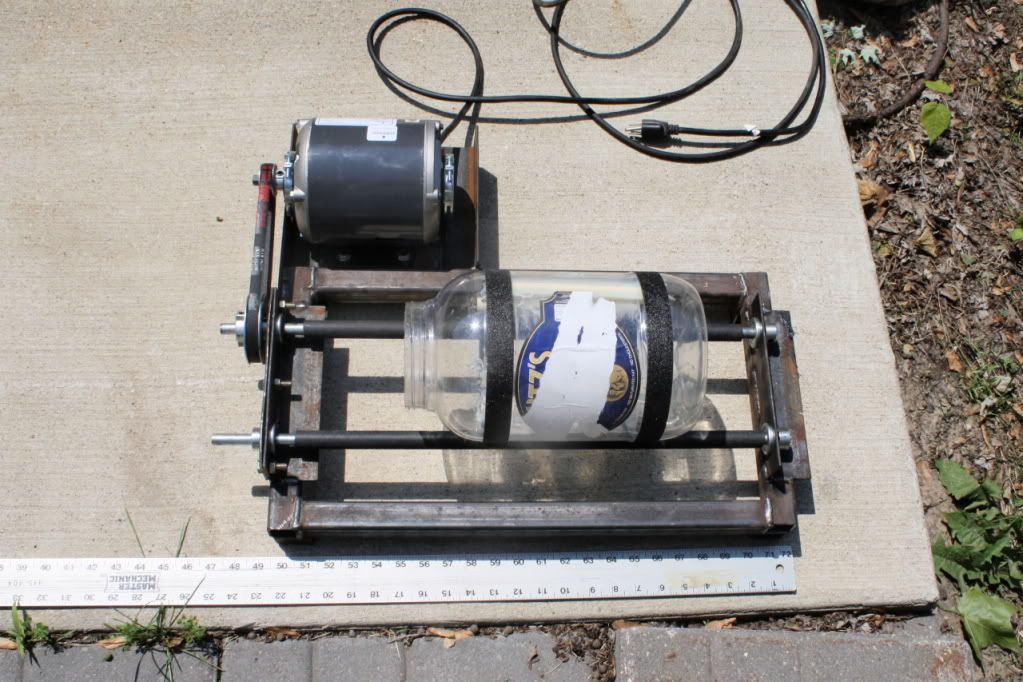

go to the wet tumbling method with stainless media but i didn't want to pay 180 for a tumbler and i wanted to be able to tumble more cases at one time than the thumler tumbler. So i decided to build my own. I did research and found some pictures of others that had build their own. I had some scrap metal laying around my shop so i drew up some plans and welded some 1 1/4" square tubing for my base. I used 2" angle iron for the bearing supports. I used a hole saw to cut the 1 3/8" holes for the bearings. on the one end i tack welded the bearings in. on the other end i made a piece of flat steel and cut 1 1/8" holes in it to hold the bearings in so you could remove and install the shafts after the rubber hose was put on the shafts. Speaking of that i used some 1/2" heater hose to cover the drive shafts and give some grip. this is the up dated parts list for newest design

edit on 10-5-12 adding parts list for most up to date design This should be the list for the frame. if you want the 6" drum stuff i will have to dig that up but it is 6" sdr 35 sewer pipe with a 6" cap and a 6-4 inch reducer with 4" flex cap reducer at lowes http://www.lowes.com/pd_182570-676-6P07_4294765356__?productId=3609256&Ns=p_product_qty_sales_dollar|1&pl=1¤tURL=%3FNs%3Dp_product_qty_sales_dollar%7C1&facetInfo= cap at lowes http://www.lowes.com/pd_122863-676-6P06_4294765356__?productId=3575136&Ns=p_product_qty_sales_dollar|1&pl=1¤tURL=%3FNs%3Dp_product_qty_sales_dollar%7C1&facetInfo= 4" rubber cap is an american valve flexible cap part number RPC 100 1.7 foot 1 ¼” square tubing 2.1 ––1/8 to3/16 flat plate steel 6.5x7 inches 3.4 – half inch pillow block bearings http://www.ebay.com/itm/NEW-High-Quality-1-2-Set-Screw-Pillow-Block-Bearing-UCP201-08-/271046997616?pt=LH_DefaultDomain_0&hash=item3f1ba8f670 4.2—1/2 inc zinc plated rods –– I buy 36” and cut to size like this http://www.homedepot.com/h_d1/N-25ecodZ5yc1v/R-202183547/h_d2/ProductDisplay?catalogId=10053&langId=-1&keyword=zinc+rod&storeId=10051#.UG7Nypjqss0 5.40 “ of ½” heater hose 6.8—3/8x2 ½ bolts 7.2 – ¼”x3 ½ bolts 8.4—5/16x1 bolts 9.12 – 5/16 flange nuts 10.8 – 3/8 flange nuts 11. 4 – ¼ nuts 12.2 – 1/4x3/4 bearings like these http://www.ebay.com/itm/2-R4A-2RS-Premium-seal-bearing-1-4-x-3-4-x-9-32-ABEC3-C3-R4A-RS-bearings-/140687183130?pt=LH_DefaultDomain_0&hash=item20c19c0d1a 13.1 – 3k771 dayton ¼ hp electric motor 14.1 – A21 belt 15.1 – 4” pulley for ½” shaft http://www.amazon.com/gp/product/B00004RAOS/ref=oh_details_o04_s00_i01 16.1 – 1 ½” pulley for ½” shaft http://www.amazon.com/gp/product/B00004RAO2/ref=oh_details_o04_s00_i00 17.4 –– rubber feet http://www.ebay.com/itm/250847857418?ssPageName=STRK:MEWNX:IT&_trksid=p3984.m1497.l2649 here is the frame rough drawing

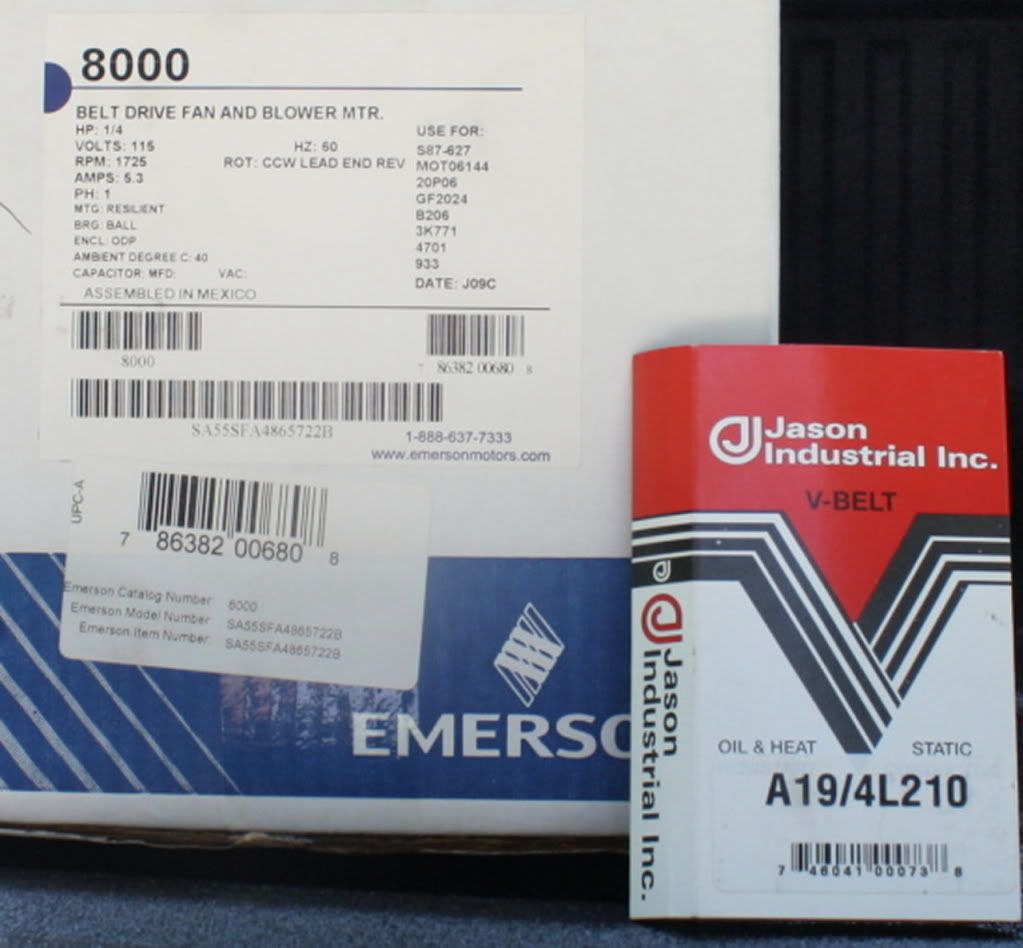

Rough bill of materials: Emerson 8000 1/4hp electric motor $78 A19 V-belt $3.25 4 –– 152-08005 nova set collars $2.00 each $8 total 4 –– 215-020 stens wheel bearings 1/2" x1 3/8" $2.50 each $10.00 total 2 –– 1/2" zinc plated steel shafts 36" long $5.00 each $10 total 1 –– 1 1/2" aluminum pulley $3.50 1 –– 3" aluminum pulley $4.25 4 foot 1/2" heater hose 2 inch angle iron as needed 1 1/4" square tubing 7"x7"x 1/8" piece of flat steel Edited to add –– With all the questions i have had. here is a link that i used to calculate my rpms. you can play with it and figure out what you need i shoot for 60-80 rpm the thumler is 30 rpm from what i remember. rpm calculator I started taking pictures late so here are the first pics from after i got the frame welded together.

here are the bearings and collars I used. i also purchased 2 - 36" 1/2" zinc plated steel rods for the shafts

This is the electric motor i used. i picked it up on sale at my local blain's farm and fleet for 78 bucks Also pictured is the belt i used from my norby's farm fleet. the pulleys used are a 1 1/2" pulley for a 1/2" shaft and a 3" for a 1/2" shaft

Here are the final pictures with a ruler in place to give an idea of demensions.

|

|

|

|

|

very impressive, you get a chance to tumble anything in it yet?

|

|

|

|

|

First thing – I love it! Being a DIY guy, I think if you have the time and skill to make it, more power to you. The frame, motor, runners all look good to me, one potential problem I can see at this point is the tumbler bottle itself. First, it is small and so your capacity as it relates to brass processed will be limited. This is the minor problem as you can always scale up since your setup looks like it can handle significant greater capacity. The more significant problem I see is you are using a round tumbler bottle. This is understandable since it is what will run best over the shafts. The reason I think this may cause a problem is if the bottle is round, the brass and media will likely just slide over its internal surface and as a result, you will not get much tumbling action. If you look at the design of the Thumbler Tumbler, the cross sectional shape of the tumbling chamber is in fact hexagonal in shape. I think it is in fact this shape which causes both the brass and media to tumble over each other and it is this rubbing action which cleans the brass.

Now, if you build a hexagonal chamber, the other thing to keep in mind is that Thumbler lines the chamber with rubber. Now this certainly will seal and insulate sound better than a hard surface chamber, but I also wonder if part of its duty is to prevent damage to the brass (or rocks) from hitting the hard surface - just wondering on this one. |

|

|

|

|

Originally Posted By JDann24:

very impressive, you get a chance to tumble anything in it yet? i put some shells in it to test it and it seems to work good. waiting on my stainless media it will be here on tuesday. my only concern is my jug if it don't work i have another idea that i will be working on monday when i go see my neighbor at my shop they are a plumbing shop and i want to see if they have a small piece of 8" or 10" pvc pipe. |

|

|

|

|

Originally Posted By BIGGDAWG: Originally Posted By jlow: First thing – I love it! Being a DIY guy, I think if you have the time and skill to make it, more power to you. The frame, motor, runners all look good to me, one potential problem I can see at this point is the tumbler bottle itself. First, it is small and so your capacity as it relates to brass processed will be limited. This is the minor problem as you can always scale up since your setup looks like it can handle significant greater capacity. The more significant problem I see is you are using a round tumbler bottle. This is understandable since it is what will run best over the shafts. The reason I think this may cause a problem is if the bottle is round, the brass and media will likely just slide over its internal surface and as a result, you will not get much tumbling action. If you look at the design of the Thumbler Tumbler, the cross sectional shape of the tumbling chamber is in fact hexagonal in shape. I think it is in fact this shape which causes both the brass and media to tumble over each other and it is this rubbing action which cleans the brass. Now, if you build a hexagonal chamber, the other thing to keep in mind is that Thumbler lines the chamber with rubber. Now this certainly will seal and insulate sound better than a hard surface chamber, but I also wonder if part of its duty is to prevent damage to the brass (or rocks) from hitting the hard surface - just wondering on this one. I got the container thing covered i appreciate your input. I epoxied some plastic water pipe in the container to agitate the brass and make it tumble. here is a picture http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3380.jpg http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3378.jpg and if it don't work i can always buy a thumler drum. but i have plans on making a larger drum from pvc plastic pipe if i can round up some small pieces locally Good move with the plastic water pipe insert inside the container, that would probably do the trick. The only other thing I would say is to seal those pipes well or the media will get into them. Definitely do not use anything made of iron inside the container since the Lemishine will eat it up and make a real mess of the solution and your brass. |

|

|

|

|

Good move with the plastic water pipe insert inside the container, that would probably do the trick. The only other thing I would say is to seal those pipes well or the media will get into them. Definitely do not use anything made of iron inside the container since the Lemishine will eat it up and make a real mess of the solution and your brass.

Thanks yes i filled the ends of the pipe with black silicone i didn't want water or cases or media getting in there. this one is just to get me going till i can get the bigger one i want. then i will keep it for smaller batches but it holds 1.75 gallons. |

|

|

|

|

Nice job.

|

|

|

"They're telling us they'd rather die than come out and surrender....so.. They're gonna die..."

|

|

Nice job! I bet a chunk of 10" pvc with some caps would really increase the amount you can tumble at one time. Your motor certainly looks capable of more!

Makes me wish I had welding skills ;) |

|

|

|

|

Excellent DIY thread.

Keep the updates comming on your new drum. |

|

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

|

Originally Posted By Dan3103:

Nice job! I bet a chunk of 10" pvc with some caps would really increase the amount you can tumble at one time. Your motor certainly looks capable of more! Makes me wish I had welding skills ;) Build one from wood. It will work as well. Varnish it up and it will look great. |

|

|

US 2010 budget: $3.55 Trillion

2010 costs: $4.47T Revenues: $2.22T Deficit spending: $960B in 2008, $1.42T in 2009 20 January 2013 - The End of an Error < |

|

Originally Posted By AeroE: I was thinking of doing just that! This thread has inspired me––––especially since I already have 2 or 3 motors in the garage doing nothing.Build one from wood. It will work as well. Varnish it up and it will look great. |

|

|

|

|

Originally Posted By AeroE:

Originally Posted By Dan3103:

Nice job! I bet a chunk of 10" pvc with some caps would really increase the amount you can tumble at one time. Your motor certainly looks capable of more! Makes me wish I had welding skills ;) Build one from wood. It will work as well. Varnish it up and it will look great. That is something i never thought of. might have to look into that. What shape would you make it? octagon like the thumler? wonder if square would work with circle caps? darn now you got me thinking Aeroe |

|

|

|

|

I was thinking that AeroE was talking about the frame for the runners and motor. One could build the drum but would definitely buy the rubber liner and gasket since I think the water/soap/Lemishine/SS media would be a bit harsh on the exposed wood? |

|

|

|

|

Do you think that setup would have enough power if you put a 5gal water jug(office water machine type) on top and filled it with say 1500-2000 pcs of 45acp at a time?

I have been thinking about building one but I want to make a large one so I only have to do one tumbling process for all my brass at a time. Mike. |

|

|

|

|

Originally Posted By mikeg1005:

Do you think that setup would have enough power if you put a 5gal water jug(office water machine type) on top and filled it with say 1500-2000 pcs of 45acp at a time? I have been thinking about building one but I want to make a large one so I only have to do one tumbling process for all my brass at a time. Mike. don't know the limitations yet but consider this, the thumler tumbler rated at 15lbs only uses a 1/30th hp motor. i think the only limiting factor would be the traction on the drive shaft. I am going to build a plastic drum that will hold 3.5- 4 gallons i will report back. –– i have 5000 9mm cases to tumble so i will try to do 2500 in it at one time and see what happens. ETA i have seen similar setups on ebay that are rated at 100lbs but they use a capacitor start 1/3hp motor. |

|

|

|

|

Excellent idea, design, and build. A couple of months of use will certainly see some tweaks and such until it runs to perfection. That's the beauty of DIY. Good job! (good exercize for the brain as well!)

|

|

|

|

|

Originally Posted By BIGGDAWG: Originally Posted By mikeg1005: Do you think that setup would have enough power if you put a 5gal water jug(office water machine type) on top and filled it with say 1500-2000 pcs of 45acp at a time? I have been thinking about building one but I want to make a large one so I only have to do one tumbling process for all my brass at a time. Mike. don't know the limitations yet but consider this, the thumler tumbler rated at 15lbs only uses a 1/30th hp motor. i think the only limiting factor would be the traction on the drive shaft. I am going to build a plastic drum that will hold 3.5- 4 gallons i will report back. –– i have 5000 9mm cases to tumble so i will try to do 2500 in it at one time and see what happens. ETA i have seen similar setups on ebay that are rated at 100lbs but they use a capacitor start 1/3hp motor. I agree that the limiting factor would be traction both between the tub/rod and motor/rod, at least these two places is where I have seen slippage if you overload the tub. If you are thinking of building a real big one i.e. 1500-2000 pcs of 45ACP at a time, remember that apart from having to build a bigger setup with a larger motor, you are going to have to buy more SS media – so there is a cost factor of being able to do a big job vs. a few small job. Of course if you run many many large jobs, it will quickly pay for itself. |

|

|

|

|

Originally Posted By BIGGDAWG:

Originally Posted By AeroE:

Originally Posted By Dan3103:

Nice job! I bet a chunk of 10" pvc with some caps would really increase the amount you can tumble at one time. Your motor certainly looks capable of more! Makes me wish I had welding skills ;) Build one from wood. It will work as well. Varnish it up and it will look great. That is something i never thought of. might have to look into that. What shape would you make it? octagon like the thumler? wonder if square would work with circle caps? darn now you got me thinking Aeroe I meant the mount for the motor and the supports. If I were to build a wood tumbler, your idea is pretty good, seal the interior with epoxy. But, I think a circular water cooler is the best idea I've seen. Ought to be able to get a gallon size jug cheap at Walmart. |

|

|

US 2010 budget: $3.55 Trillion

2010 costs: $4.47T Revenues: $2.22T Deficit spending: $960B in 2008, $1.42T in 2009 20 January 2013 - The End of an Error < |

|

Originally Posted By AeroE:

[I meant the mount for the motor and the supports. If I were to build a wood tumbler, your idea is pretty good, seal the interior with epoxy. But, I think a circular water cooler is the best idea I've seen. Ought to be able to get a gallon size jug cheap at Walmart. The problem with that is that it leaks. I bought three different water jugs/brands and they all leak. Either out of the lid, or the spigot. 'Borg |

|

|

|

|

I was planning to use just walnut media... not stainless.

MIke. |

|

|

|

|

Originally Posted By We-rBorg: Originally Posted By AeroE: [I meant the mount for the motor and the supports. If I were to build a wood tumbler, your idea is pretty good, seal the interior with epoxy. But, I think a circular water cooler is the best idea I've seen. Ought to be able to get a gallon size jug cheap at Walmart. The problem with that is that it leaks. I bought three different water jugs/brands and they all leak. Either out of the lid, or the spigot. 'Borg There are places on the web where you can just buy the Thumler's jug - except for a minor flaws, it is in general a very good design and it will never leak the way it is setup. |

|

|

|

|

Originally Posted By GWhis:

Excellent idea, design, and build. A couple of months of use will certainly see some tweaks and such until it runs to perfection. That's the beauty of DIY. Good job! (good exercize for the brain as well!) I like the plastic pipe agitators. Seems like it would build up and then waterfall over pretty good. Good Job! Brett |

|

|

|

|

Originally Posted By jlow:

Originally Posted By We-rBorg:

Originally Posted By AeroE:

[I meant the mount for the motor and the supports. If I were to build a wood tumbler, your idea is pretty good, seal the interior with epoxy. But, I think a circular water cooler is the best idea I've seen. Ought to be able to get a gallon size jug cheap at Walmart. The problem with that is that it leaks. I bought three different water jugs/brands and they all leak. Either out of the lid, or the spigot. 'Borg There are places on the web where you can just buy the Thumler's jug - except for a minor flaws, it is in general a very good design and it will never leak the way it is setup. They're almost half the cost of a complete machine. Besides, where's the fun in buying one if a custom barrel can be made? |

|

|

US 2010 budget: $3.55 Trillion

2010 costs: $4.47T Revenues: $2.22T Deficit spending: $960B in 2008, $1.42T in 2009 20 January 2013 - The End of an Error < |

|

Looks great. I have been pondering building my own similar to yours. I got the design ideas from someone selling similar types on Ebay. They have units that do up to 100lbs. I think it is a 10" drum. They use all pvc parts. Pipe with an end cap on one end and a X" X 4" reduce coupling on the other end with a fernco 4" cap that comes with a large hose/band clamp for securing to the reducer. Makes it all water tight. I asked the Manufacturer about the drum not having anything in the way of paddles in the drum and about rotation speed. The response I got was,

The speed of the barrel is 80-90 rpm, it is smooth on the inside and relies on centrifagal force th cause the load on the inside to pass the 120-140 degree mark from the bottom then it tumbles...the hex barrels usually turn at about 1/2 this speed....the increased speed of the barrel is the main reason that round barrels get the job done much faster than the hex.

I was going to make my own using pillow block bearings, with 3/4" shafts, and a steel frame like yours. I have a really nice 3/4 hp motor that I am not using that I was going to use for this project. I then thought well I have a 3cu ft poly cement mixer, I wonder if that would work as well? |

|

|

Never under estimate the power of stupid people in large numbers.

Helping Mall Ninjas, become real Ninjas, since 2008. |

|

Originally Posted By Flamethrower:

Looks great. I have been pondering building my own similar to yours. I got the design ideas from someone selling similar types on Ebay. They have units that do up to 100lbs. I think it is a 10" drum. They use all pvc parts. Pipe with an end cap on one end and a X" X 4" reduce coupling on the other end with a fernco 4" cap that comes with a large hose/band clamp for securing to the reducer. Makes it all water tight. I asked the Manufacturer about the drum not having anything in the way of paddles in the drum and about rotation speed. The response I got was, The speed of the barrel is 80-90 rpm, it is smooth on the inside and relies on centrifagal force th cause the load on the inside to pass the 120-140 degree mark from the bottom then it tumbles...the hex barrels usually turn at about 1/2 this speed....the increased speed of the barrel is the main reason that round barrels get the job done much faster than the hex.

I was going to make my own using pillow block bearings, with 3/4" shafts, and a steel frame like yours. I have a really nice 3/4 hp motor that I am not using that I was going to use for this project. I then thought well I have a 3cu ft poly cement mixer, I wonder if that would work as well? I have heard of guys using cheap cement mixers from harbor freight to tumble brass. i may upgrade to pillow blocks with bearings down the road if these bearings fail. but it would have cost 3-5 times more to go with that set up i was trying to get by cheap

i saw those on ebay too. i am in the process of acquiring a small piece of 8 or 10 inch pvc to make a drum out of. the home stores around here don't carry it and make you order 10 foot lengths at 140 bucks. when i make mine i am going to glue some strips in it like i did my first drum to make things tumble. good luck with your build. i think the 3/4 shafts may be over kill but heavy duty is better than light duty. |

|

|

|

|

Originally Posted By AeroE: Originally Posted By jlow: Originally Posted By We-rBorg: Originally Posted By AeroE: [I meant the mount for the motor and the supports. If I were to build a wood tumbler, your idea is pretty good, seal the interior with epoxy. But, I think a circular water cooler is the best idea I've seen. Ought to be able to get a gallon size jug cheap at Walmart. The problem with that is that it leaks. I bought three different water jugs/brands and they all leak. Either out of the lid, or the spigot. 'Borg There are places on the web where you can just buy the Thumler's jug - except for a minor flaws, it is in general a very good design and it will never leak the way it is setup. They're almost half the cost of a complete machine. Besides, where's the fun in buying one if a custom barrel can be made? Just giving options since people are having some problems, not saying that they have to go that way. On the flip side, there was obviousely quite a bit of engineering and testing that they did put in, so the price is not unreasonable. What one could potentially do is the build the hex casing and just buy the rubber inner tube and seal – always useful to not limit one’s options especially if there are roadblocks to getting the right parts on a home build. |

|

|

|

|

Originally Posted By BIGGDAWG:

Originally Posted By Flamethrower:

Looks great. I have been pondering building my own similar to yours. I got the design ideas from someone selling similar types on Ebay. They have units that do up to 100lbs. I think it is a 10" drum. They use all pvc parts. Pipe with an end cap on one end and a X" X 4" reduce coupling on the other end with a fernco 4" cap that comes with a large hose/band clamp for securing to the reducer. Makes it all water tight. I asked the Manufacturer about the drum not having anything in the way of paddles in the drum and about rotation speed. The response I got was, The speed of the barrel is 80-90 rpm, it is smooth on the inside and relies on centrifagal force th cause the load on the inside to pass the 120-140 degree mark from the bottom then it tumbles...the hex barrels usually turn at about 1/2 this speed....the increased speed of the barrel is the main reason that round barrels get the job done much faster than the hex.

I was going to make my own using pillow block bearings, with 3/4" shafts, and a steel frame like yours. I have a really nice 3/4 hp motor that I am not using that I was going to use for this project. I then thought well I have a 3cu ft poly cement mixer, I wonder if that would work as well? I have heard of guys using cheap cement mixers from harbor freight to tumble brass. i may upgrade to pillow blocks with bearings down the road if these bearings fail. but it would have cost 3-5 times more to go with that set up i was trying to get by cheap

i saw those on ebay too. i am in the process of acquiring a small piece of 8 or 10 inch pvc to make a drum out of. the home stores around here don't carry it and make you order 10 foot lengths at 140 bucks. when i make mine i am going to glue some strips in it like i did my first drum to make things tumble. good luck with your build. i think the 3/4 shafts may be over kill but heavy duty is better than light duty. I talked to one of my old suppliers yesterday and he had mentioned that PVC has gone WAY up just in the last month or so. He was saying that 6" was going up .68 cents a foot. Which may not sound like a lot but on the grand scheme of things it's a lot. I had 2 mixers both from Northern Tool. One is a metal drum, which is no longer in service. I burned up the motor after 6 months and then replaced it with a nice 3/4hp motor. Then the drive sprocket tore out a section of the drums slots that the spocket runs in. I was going to fix it, but it would be to much of a pita, so I set it out back and I will steal the motor of it. The other is the poly drum witha gearbox. It has worked well, but with the warm weather I have to put a box fan behind the motor to keep it from overheating and tripping the thermal overload. Both mixers have seen far more run time than I am sure they were designed for. Just in the last 4 days the poly drum has about 18 hours on it.  It keeps running. I like the mixer idea to save on cost of building a dedicated wet system, but in the end I may have to make it. If for nothing else to just have it. lol It keeps running. I like the mixer idea to save on cost of building a dedicated wet system, but in the end I may have to make it. If for nothing else to just have it. lol

I.m not really sure how much SS media I will need for the mixer, but I may just order 10 lbs and give it a go. Where did you get your bearings? I was looking at trying them instead of the pillow blocks. |

|

|

Never under estimate the power of stupid people in large numbers.

Helping Mall Ninjas, become real Ninjas, since 2008. |

|

Originally Posted By Flamethrower

I talked to one of my old suppliers yesterday and he had mentioned that PVC has gone WAY up just in the last month or so. He was saying that 6" was going up .68 cents a foot. Which may not sound like a lot but on the grand scheme of things it's a lot. I had 2 mixers both from Northern Tool. One is a metal drum, which is no longer in service. I burned up the motor after 6 months and then replaced it with a nice 3/4hp motor. Then the drive sprocket tore out a section of the drums slots that the spocket runs in. I was going to fix it, but it would be to much of a pita, so I set it out back and I will steal the motor of it. The other is the poly drum witha gearbox. It has worked well, but with the warm weather I have to put a box fan behind the motor to keep it from overheating and tripping the thermal overload. Both mixers have seen far more run time than I am sure they were designed for. Just in the last 4 days the poly drum has about 18 hours on it.  It keeps running. I like the mixer idea to save on cost of building a dedicated wet system, but in the end I may have to make it. If for nothing else to just have it. lol It keeps running. I like the mixer idea to save on cost of building a dedicated wet system, but in the end I may have to make it. If for nothing else to just have it. lol

I.m not really sure how much SS media I will need for the mixer, but I may just order 10 lbs and give it a go. Where did you get your bearings? I was looking at trying them instead of the pillow blocks. i got the bearings at my local farm store –– norby's farm fleet. but blains had them too. i think the ss media ratio will probably be 5lbs per 500 cases but i could be wrong. going to test and see if mine ever get here. lol |

|

|

|

|

Originally Posted By BIGGDAWG: Originally Posted By Flamethrower I talked to one of my old suppliers yesterday and he had mentioned that PVC has gone WAY up just in the last month or so. He was saying that 6" was going up .68 cents a foot. Which may not sound like a lot but on the grand scheme of things it's a lot. I had 2 mixers both from Northern Tool. One is a metal drum, which is no longer in service. I burned up the motor after 6 months and then replaced it with a nice 3/4hp motor. Then the drive sprocket tore out a section of the drums slots that the spocket runs in. I was going to fix it, but it would be to much of a pita, so I set it out back and I will steal the motor of it. The other is the poly drum witha gearbox. It has worked well, but with the warm weather I have to put a box fan behind the motor to keep it from overheating and tripping the thermal overload. Both mixers have seen far more run time than I am sure they were designed for. Just in the last 4 days the poly drum has about 18 hours on it.  It keeps running. I like the mixer idea to save on cost of building a dedicated wet system, but in the end I may have to make it. If for nothing else to just have it. lol It keeps running. I like the mixer idea to save on cost of building a dedicated wet system, but in the end I may have to make it. If for nothing else to just have it. lolI.m not really sure how much SS media I will need for the mixer, but I may just order 10 lbs and give it a go. Where did you get your bearings? I was looking at trying them instead of the pillow blocks. i got the bearings at my local farm store –– norby's farm fleet. but blains had them too. i think the ss media ratio will probably be 5lbs per 500 cases but i could be wrong. going to test and see if mine ever get here. lol The amount of media I think depends on the size of the drum, the caliber you are working on, and the number of pieces of brass. The exact amount stated by SS Media can be see at this URL:

http://www.stainlesstumblingmedia.com/tips I ran a couple of batches of 9 mm brass recently and I just did a weight check and it turned out that I ran about 250 pieces of 9mm per run using 5lb of SS media, so actually very close to the 230 that they recommend. I think 500 would be pushing it not from the standpoint of your motor (which is the limiting factor for the Thumler Tumbler), but the ratio between brass and media. With 500 pieces of 9mm and 5 lb of SS media, my guess is that you will need to run it for significantly longer than 3 hours, maybe 6? Don't know, but also certainly more Lemishine and detergent. You will find out when you run it. One thing people should know about the tumbler size is as you get significantly larger in volume, the weight of the tub/water/media/brass combo will of course also increase. IMHO the weight of the Thumler's Tumbler is a good place to be since a 15 lb mass is very easy to handle when you have to fill and drain it say inside your washer’s tub many times when you fill and then later wash out the waste. So bigger is not always better, to some extend it is, but there is a sweet spot. |

|

|

|

|

What is you drum speed in RPM's?

|

|

|

Never under estimate the power of stupid people in large numbers.

Helping Mall Ninjas, become real Ninjas, since 2008. |

|

Originally Posted By Flamethrower:

What is you drum speed in RPM's? with this small drum it is right at 100 rpm maybe a little fast. looking for a 4" pulley for the drive shaft but the only ones in town are for 5/8 shaft and i have 1/2 so i will see. wish my darn media would get here so i can give it a good test

|

|

|

|

|

Originally Posted By BIGGDAWG:

Originally Posted By Flamethrower:

What is you drum speed in RPM's? with this small drum it is right at 100 rpm maybe a little fast. looking for a 4" pulley for the drive shaft but the only ones in town are for 5/8 shaft and i have 1/2 so i will see. wish my darn media would get here so i can give it a good test

I am thinking of doing a 2" and a 4". You got me excited with this and I ordered 4 3/4" greasable pillow block bearings off of Ebay. Set of 4 $36 shipped. Damn you for making me spend money. |

|

|

Never under estimate the power of stupid people in large numbers.

Helping Mall Ninjas, become real Ninjas, since 2008. |

|

cool send me a link to those pillow blocks i may have to check them out

sorry about the spending money thing but it happens lol

|

|

|

|

|

|

|

nice DIY job!

|

|

|

|

|

Originally Posted By BIGGDAWG:

here are some pictures of a batch of 40 that i ran tonight with 5 quarts water, 4lbs of brass no media, 2 tablespoons dawn and 1 table spoon lemi shine. i ran them for an hour turned out pretty good for no media. Before http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3408.jpg after http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3434.jpg http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3433.jpg http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3429.jpg Those are good results without any SS media. eta, I set the toggle on this thread to keep it out of the archives. So you can link this thread up in the tacked "Useful Threads" if you want. |

|

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

|

Originally Posted By dryflash3:

Originally Posted By BIGGDAWG:

here are some pictures of a batch of 40 that i ran tonight with 5 quarts water, 4lbs of brass no media, 2 tablespoons dawn and 1 table spoon lemi shine. i ran them for an hour turned out pretty good for no media. Before http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3408.jpg after http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3434.jpg http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3433.jpg http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3429.jpg Those are good results without any SS media. eta, I set the toggle on this thread to keep it out of the archives. So you can link this thread up in the tacked "Useful Threads" if you want. i was suprized too, the primer pockes arn't clean and the insides are a little dirty but an hour in the wet with no media is better that 6 hours in the tumbler so i can't complain |

|

|

|

|

Originally Posted By BIGGDAWG:

Originally Posted By dryflash3:

Originally Posted By BIGGDAWG:

here are some pictures of a batch of 40 that i ran tonight with 5 quarts water, 4lbs of brass no media, 2 tablespoons dawn and 1 table spoon lemi shine. i ran them for an hour turned out pretty good for no media. Before http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3408.jpg after http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3434.jpg http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3433.jpg http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3429.jpg Those are good results without any SS media. eta, I set the toggle on this thread to keep it out of the archives. So you can link this thread up in the tacked "Useful Threads" if you want. i was suprized too, the primer pockes arn't clean and the insides are a little dirty but an hour in the wet with no media is better that 6 hours in the tumbler so i can't complain Soak a couple of pieces of brass in Lemishine for 30 minutes to an hour, then poke at the carbon with a swab. What I have found is that the carbon is very soft but tenacious and needs some mechanical action to get to to let loose. Primer pockets and the interior will swipe clean without a bit of trouble, but it's not productive for buckets full of cases. |

|

|

US 2010 budget: $3.55 Trillion

2010 costs: $4.47T Revenues: $2.22T Deficit spending: $960B in 2008, $1.42T in 2009 20 January 2013 - The End of an Error < |

|

The postman just dropped off my ss media so will get to run a couple of batches tonight

and see if i can get mine to look like dryflash3's also going to buy a 4" pulley to see what slowing down the drum will do. don't know if my 100rpm is too much or not seems to work with out media so i will see. |

|

|

|

|

I've been using a sun tea jar just like that one loaded with walnut media on a home-made tumbler using an old ice cream maker motor for over 20 years without any issues. I never bothered to put anything inside it to help with the agitation like you did, it seems to do just fine without it. There's enough friction going on in there when it's loaded that it doesn't need any other help turning everything over.

Nice job!!! |

|

|

|

|

Originally Posted By BIGGDAWG:

The postman just dropped off my ss media so will get to run a couple of batches tonight and see if i can get mine to look like dryflash3's also going to buy a 4" pulley to see what slowing down the drum will do. don't know if my 100rpm is too much or not seems to work with out media so i will see. I'm in for your first bling pic. |

|

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

|

|

|

Originally Posted By BIGGDAWG:

Originally Posted By dryflash3:

Originally Posted By BIGGDAWG:

The postman just dropped off my ss media so will get to run a couple of batches tonight and see if i can get mine to look like dryflash3's also going to buy a 4" pulley to see what slowing down the drum will do. don't know if my 100rpm is too much or not seems to work with out media so i will see. I'm in for your first bling pic. That's really good for 1 hour. well got one batch done but only could tumble for an hour because my agitators came unglued from my barrel. still pretty good just not as shinny as i wanted but the insides and primer pockets are all clean. have to make some modifications and try again tomorrow. this was 5lbs media, 4.6 lbs 9mm brass, 3 tablespoons dawn and 1 tablespoon lemi shine. http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3436.jpg http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3435.jpg http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3443.jpg http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3442.jpg http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3441.jpg http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3439.jpg |

|

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

|

Originally Posted By BIGGDAWG:

here is the media i got from pellets llc http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3447.jpg http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3444.jpg What's the diameter? My Buffalo Arms media is .041. |

|

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

|

Originally Posted By dryflash3:

Originally Posted By BIGGDAWG:

here is the media i got from pellets llc http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3447.jpg http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3444.jpg What's the diameter? My Buffalo Arms media is .041. they are .040 ETA it was 55 shipped for 10lbs. |

|

|

|

|

Ok

Motor?––Check 2" and 4" pulleys?––Check Frame Steel?––Check Roller Shafts?––Check Pillow Block Bearings?––Check––On order Need 3/4" heater hose 6" pvc cap 6"X4" pvc reducer coupling 10" pvc cap 10"X4" pvc reducer coupling 2-4" rubber Fernco caps. Mounting hardware 10lbs of ss media I stopped by the plumbing supply house I went to with my old job and called in a favor. I got 2 drop off pieces of PVC one 6" and one 10". Each one is about 3' long. I got lucky as they gave them to me for free. If I did my math correct the 6" at 1' will yeald 1 gallon of usable space and the 10" at 14" will yeald 5 gallons, give or take. Like I always do I went a little overboard when it came to material thickness. I used 1-1/2" square tube with a 3/16" wall.  For the motor mount I went with the same tube but with .250" wall. I reall just wanted to tap the holes for the motor instead of using bolts with nuts. For the motor mount I went with the same tube but with .250" wall. I reall just wanted to tap the holes for the motor instead of using bolts with nuts.

I now just need time to put this together. |

|

|

Never under estimate the power of stupid people in large numbers.

Helping Mall Ninjas, become real Ninjas, since 2008. |

|

Originally Posted By Flamethrower:

Ok Motor?––Check 2" and 4" pulleys?––Check Frame Steel?––Check Roller Shafts?––Check Pillow Block Bearings?––Check––On order Need 3/4" heater hose 6" pvc cap 6"X4" pvc reducer coupling 10" pvc cap 10"X4" pvc reducer coupling 2-4" rubber Fernco caps. Mounting hardware 10lbs of ss media I stopped by the plumbing supply house I went to with my old job and called in a favor. I got 2 drop off pieces of PVC one 6" and one 10". Each one is about 3' long. I got lucky as they gave them to me for free. If I did my math correct the 6" at 1' will yeald 1 gallon of usable space and the 10" at 14" will yeald 5 gallons, give or take. Like I always do I went a little overboard when it came to material thickness. I used 1-1/2" square tube with a 3/16" wall.  For the motor mount I went with the same tube but with .250" wall. I reall just wanted to tap the holes for the motor instead of using bolts with nuts. For the motor mount I went with the same tube but with .250" wall. I reall just wanted to tap the holes for the motor instead of using bolts with nuts.

I now just need time to put this together. sounds like it is going to be a beast post up some pics when you get done. |

|

|

|

|

Originally Posted By BIGGDAWG:

Originally Posted By dryflash3:

Originally Posted By BIGGDAWG:

here is the media i got from pellets llc http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3447.jpg http://i4.photobucket.com/albums/y124/BIGGDAWG800/IMG_3444.jpg What's the diameter? My Buffalo Arms media is .041. they are .040 ETA it was 55 shipped for 10lbs. So almost the same dimensions. Price about the same. Good to know 2 sources. |

|

|

Selling agent for Algores carbon credit scam.

Shooting and Reloading, one hobby feeds the other. |

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.