|

Posted: 1/5/2015 10:07:17 AM EDT

I have decided I want a suppressor, and after tons of reading I have decided to build my own instead of purchasing one.

Reasons why, cost is one of them but not the deciding factor. Time was a huge one, to be able to efile a form 1 and get approved in about a month, is better than waiting. Ease, a basic homemade build can be done pretty easily with no special tools. Tinker factor, I like to do things myself. Shooting my reloads out of the guns I built, through a suppressor I built has a nice ring to it. So, with those reason and more I have decided to take this project on, and do a simple write up in case anyone else wants to do one. I will reference a few different ways to do things and types of materials but the one I will be building in this write will be a .30 caliber 8.5" Titanium with Aluminum ends, on a SDTA muzzle break, with 45 degree baffles. |

|

|

|

Reserved for parts list, cost, links & other info.

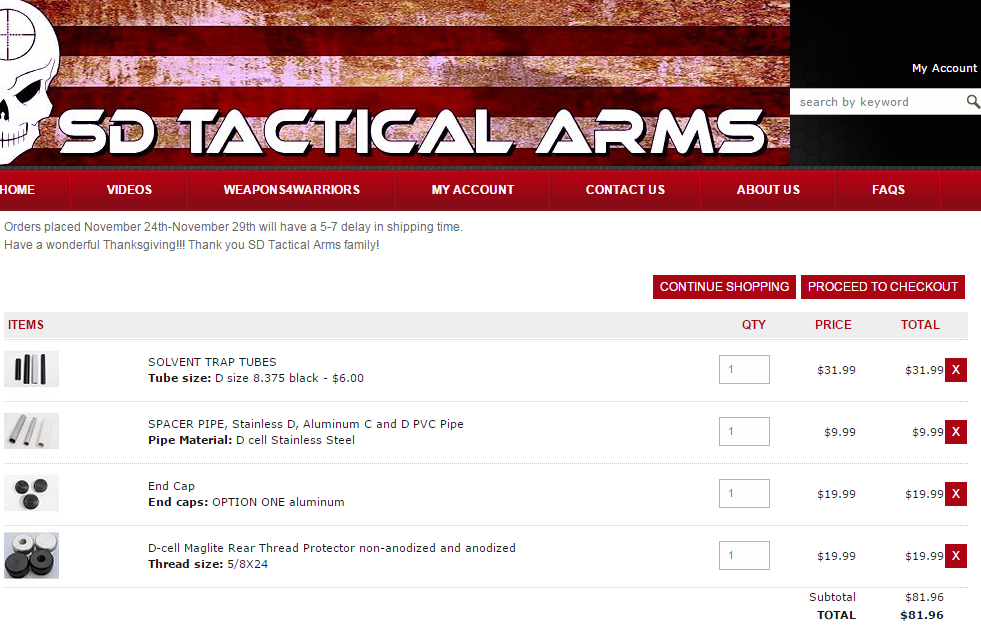

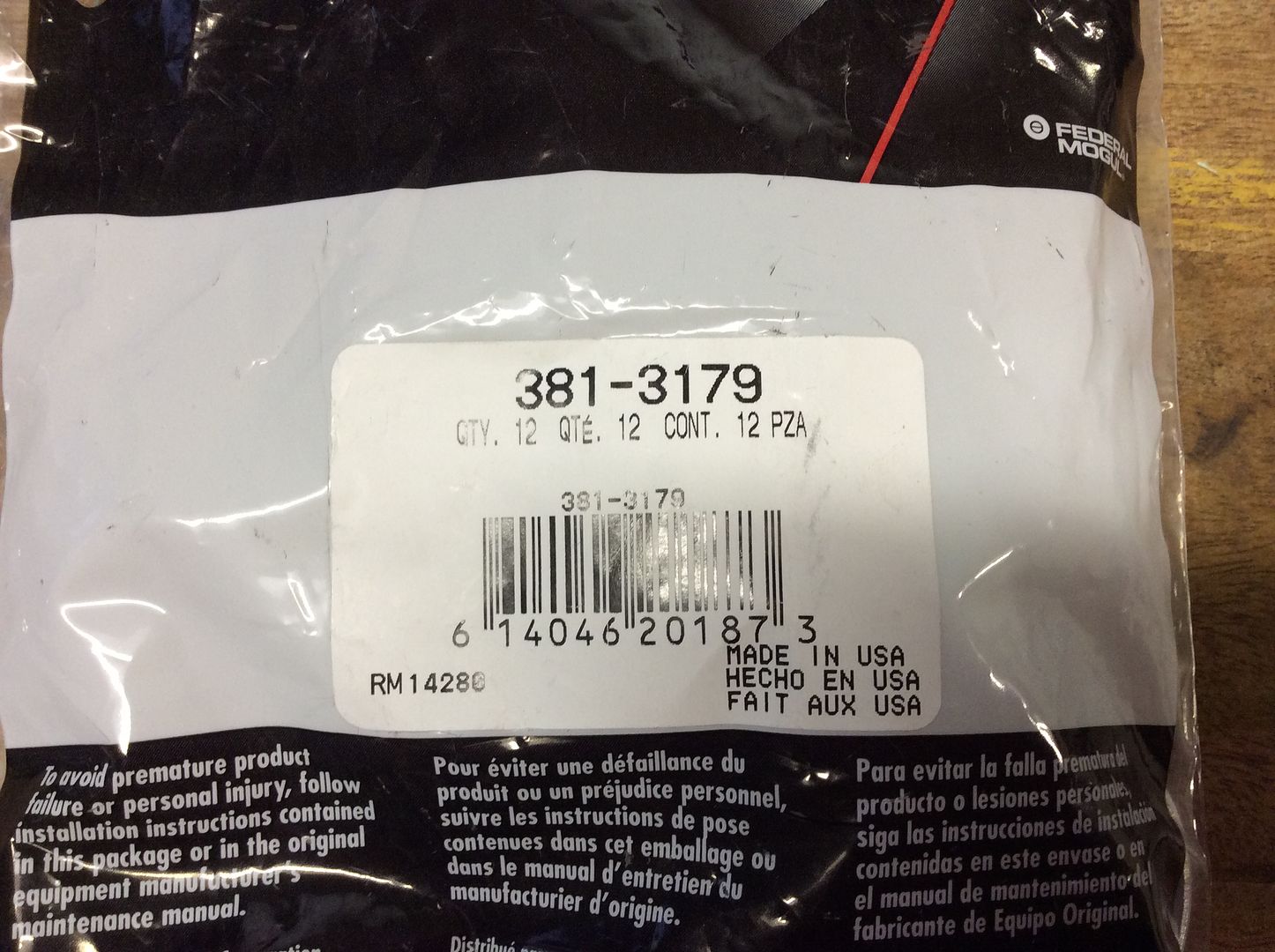

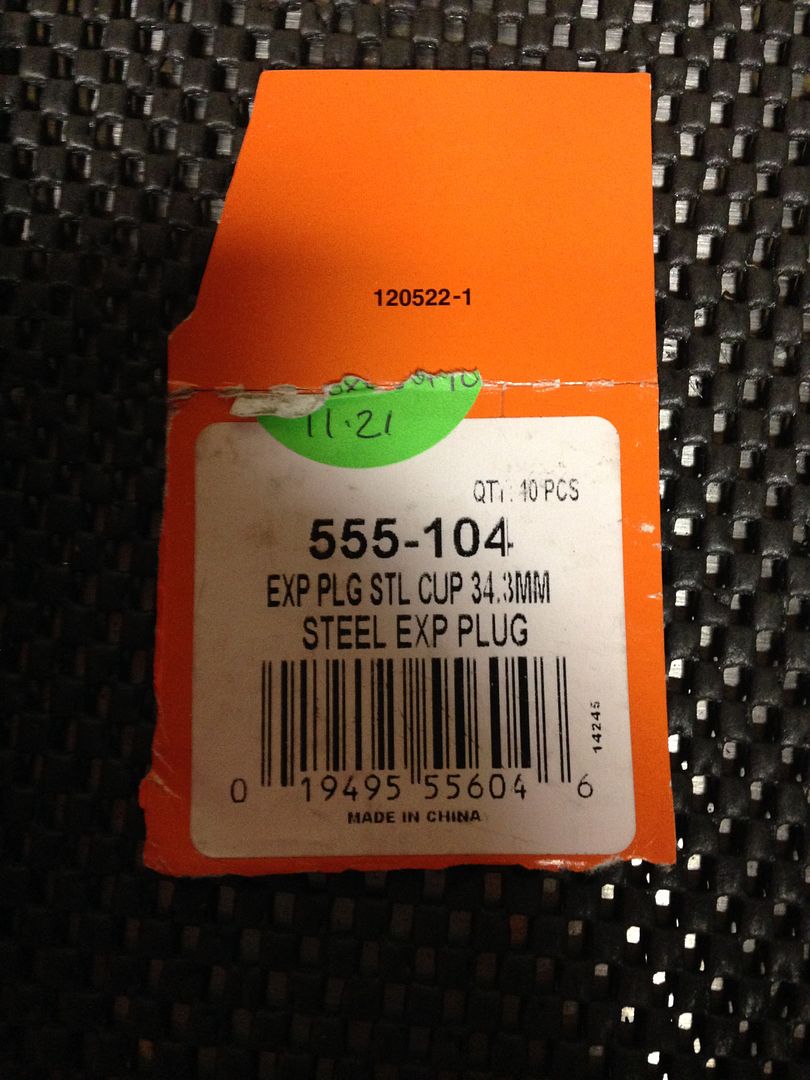

Carbon Steel tube, Alum ends, direct thread on Tax stamp, $200 required. Break to can adapter (thread protector D-Cell), $19.99 Required. http://sdtacticalarms-com.3dcartstores.com/D-cell-Maglite-Rear-Thread-Protector-non-anodized-and-anodized_p_15.html 8.375" Steel tube D-Cell, $30.99 required if not using a donor flashlight for a tube. http://sdtacticalarms-com.3dcartstores.com/SOLVENT-TRAP-TUBES_p_47.html SS D-Cell Spacer and blast tube, $10.00 required. http://sdtacticalarms-com.3dcartstores.com/Stainless-D-Aluminum-C-and-D-PVC-Pipe_p_41.html Freeze Plugs 381-3179, $11 for a 12 pack at Napa required. http://www.napaonline.com/Catalog/CatalogItemDetail.aspx/Expansion-Plug-1-350-34-300-mm/_/R-SEP3813179_0186397517 End Cap, $19.99 Aluminum D Cell. http://sdtacticalarms-com.3dcartstores.com/End-Caps_p_50.html Total Estimated total for Steel tube with Aluminum ends, direct thread on build parts: $92.96 + Tax stamp $200 = $292.96 Total

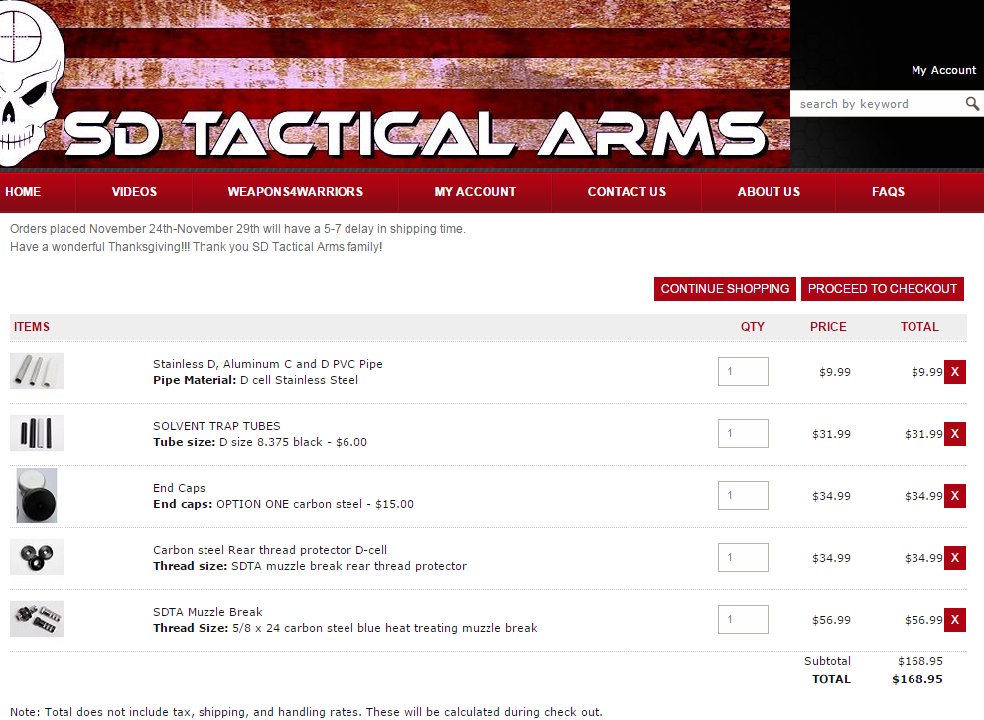

Carbon Steel Parts list Tax stamp, $200 required. Muzzle Break, $56.99 not required. You can use an adapter that threads directly to the barrel. http://sdtacticalarms-com.3dcartstores.com/SDTA-Muzzle-Break_p_65.html Break to can adapter (thread protector D-Cell), $34.99 Required. http://sdtacticalarms-com.3dcartstores.com/Carbon-steel-Rear-thread-protector-D-cell_p_70.html 8.375" Steel tube D-Cell, $30.99 required if not using a donor flashlight for a tube. http://sdtacticalarms-com.3dcartstores.com/SOLVENT-TRAP-TUBES_p_47.html SS D-Cell Spacer and blast tube, $10.00 required. http://sdtacticalarms-com.3dcartstores.com/Stainless-D-Aluminum-C-and-D-PVC-Pipe_p_41.html Freeze Plugs 381-3179, $11 for a 12 pack at Napa required. http://www.napaonline.com/Catalog/CatalogItemDetail.aspx/Expansion-Plug-1-350-34-300-mm/_/R-SEP3813179_0186397517 End Cap, $34.99 Carbon Steel D Cell. http://sdtacticalarms-com.3dcartstores.com/End-Caps_p_50.html Total Estimated total for Steel build parts: $178.96 + Tax stamp $200 = $378.96 Total

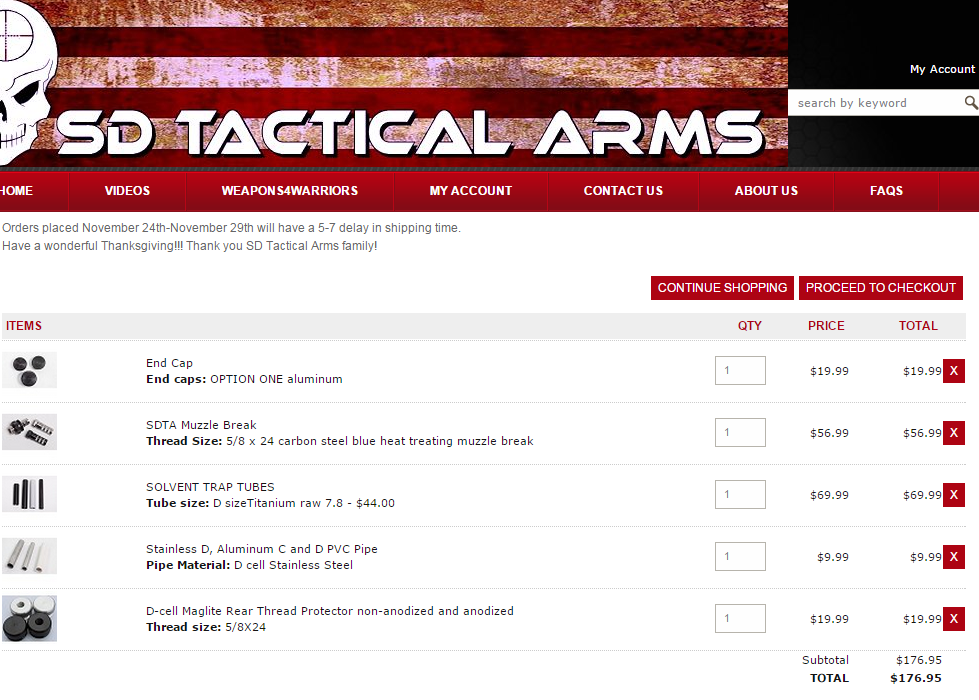

Titanium build Tax stamp, $200 required. Muzzle Break, $56.99 not required. You can use an adapter that threads directly to the barrel. http://sdtacticalarms-com.3dcartstores.com/SDTA-Muzzle-Break_p_65.html Break to can adapter (thread protector D-Cell), $19.99 Required add the option to the break selection. http://sdtacticalarms-com.3dcartstores.com/SDTA-Muzzle-Break_p_65.html 8" Titanium tube D-Cell, $69.99 required if not using a donor flashlight for a tube. http://sdtacticalarms-com.3dcartstores.com/SOLVENT-TRAP-TUBES_p_47.html SS D-Cell Spacer and blast tube, $10.00 required. http://sdtacticalarms-com.3dcartstores.com/Stainless-D-Aluminum-C-and-D-PVC-Pipe_p_41.html Freeze Plugs 381-3179, $11 for a 12 pack at Napa required. End Cap, $19.99 Aluminium D Cell. http://sdtacticalarms-com.3dcartstores.com/End-Caps_p_50.html Total Estimated total for Titanium Build parts: $187.96 + Tax stamp $200 = $397.96 Total

Purchased tools Depending on the style you want to do, there are different methods. The most basic method is not angling the baffles at all. You just use the centering tool and a drill to drill the middle to the desired caliber. I will be testing non angle baffles, 45 deg angled baffles and 60 degree baffles. I may test different combinations of the baffles as well, along with different spacing arrangements. Center Tool $19.99, required. http://sdtacticalarms-com.3dcartstores.com/Centering-Tools_c_17.html Puller tip 45 degree, required if adding an angle to baffles. If you don't have a puller to use the tip off of, there are replacement tips online for $10-$15. 60 Degree tip, required if wanting this angle on your baffles. It is recommend you start with 45 then use the 60 to prevent distorting the baffle. $11.83 http://www.amazon.com/dp/B00012YFKI/ref=sr_ph?ie=UTF8&qid=1416935804&sr=1&keywords=grizzly+mt2 Puller tip that is close to 60 degrees. just another example of something you can use. $6.07. http://www.toolup.com/proto_j4012t_puller-tip-detachable-sta.aspx And then there is a complete setup for the guy that will be making multiple baffles. I was going to produce something like this, but for the price it's good enough. My only concern is that it appears to be a 45 degree angle and not a 60. $110, http://www.ebay.com/itm/221612690113?_trksid=p2060778.m2763.l2649&ssPageName=STRK%3AMEBIDX%3AIT Baffles: There are two brands of baffles that I have found will fit. This is the one I linked to above.

This part number is stronger and slightly longer in the depth. They also fit tighter in the tube, and require just a slight bit of pressure to push down the tube. These may create a better seal, but either will work just fine.

|

|

|

|

Thank you. IMO this thread needs to be stickied. This is the best "how to" without all the other discussion.

|

|

|

|

For guys that are only building one suppressor, it might be cool to "Rent-a-Tool" on that forming tool and pass around the savings. So that you're whole budget isn't blown a tool that cost more than the can.

|

|

|

|

Another thread I need to keep an eye on. Got clearance from the tower to get my stamp, so this is very helpful. Great write up!

|

|

|

|

|

|

Subbed.. I've been contemplating this for a while, especially for tinker factor.

|

|

|

|

Great write up OP! I like how it didnt turn into I wish I bought a lathe thread. What Orings did you use? Im so trying to talk the other half into letting me do this.

|

|

|

|

|

|

|

|

Quoted:

I updated the results post to show the weight. I will get the overall length tonight. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Nice, how much does it weigh? I updated the results post to show the weight. I will get the overall length tonight. Can you estimate what the weight of the build would be with the Ti tube instead of the carbon steel? I'm waffling between spending the extra money on the Ti or dealing with some extra ounces on the carbon steel. |

|

|

|

Quoted:

Reserved for results In its current configuration, 1 ss blast chamber and 15 freeze plug baffles with aluminum ends came in weighing more than I expected with the Titanium tube 21.8oz or 1lb 5.8oz. I looked at removing a few baffles and replacing with spacers, but the spacer material weighs over twice then the baffles so there would be no weight savings. <a href="http://s296.photobucket.com/user/WeberSteve/media/299AB9AC-C3E0-41D4-B97F-CCC84B4CD9AC_zpsek8mcfmd.jpg.html" target="_blank">http://i296.photobucket.com/albums/mm198/WeberSteve/299AB9AC-C3E0-41D4-B97F-CCC84B4CD9AC_zpsek8mcfmd.jpg</a> <a href="http://s296.photobucket.com/user/WeberSteve/media/5AAD4AE7-5D03-40E7-AADD-DF1512F038A9_zpss64m8n0y.jpg.html" target="_blank">http://i296.photobucket.com/albums/mm198/WeberSteve/5AAD4AE7-5D03-40E7-AADD-DF1512F038A9_zpss64m8n0y.jpg</a> View Quote Steel spacers (.05" thick) weight almost half the weight of a freeze plug for the same length taken up. Each freeze plug weights .76oz before drilling the center hole, so removing 1 freeze plug and replacing it with a spacer is equal to 1/3oz savings, going with Titanium or aluminum will yield an even larger savings. |

|

|

|

How long is your titanium tube (tube itself)?

You are killing yourself weight wise with all those freeze plugs. Also, can you do me a favor and weigh a 16.9oz bottle of water. |

|

|

|

Wow, nice work. This is almost exactly what I plan on doing once I get around to doing my form 1 only I was going to try to find a way around using the baffle forming tool. Maybe I will go together with some friends and get one, it appears to make it much easier.

That does seem excessive on the number of baffles, but what do I know? Thanks for the pics! |

|

|

|

Quoted:

Can you estimate what the weight of the build would be with the Ti tube instead of the carbon steel? I'm waffling between spending the extra money on the Ti or dealing with some extra ounces on the carbon steel. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Quoted:

Nice, how much does it weigh? I updated the results post to show the weight. I will get the overall length tonight. Can you estimate what the weight of the build would be with the Ti tube instead of the carbon steel? I'm waffling between spending the extra money on the Ti or dealing with some extra ounces on the carbon steel. I'm using the Ti tube. |

|

|

|

Going off of your pictures, it doesn't look like you are screwing the endcaps in all the way.

|

|

|

|

Quoted:

Steel spacers (.05" thick) weight almost half the weight of a freeze plug for the same length taken up. Each freeze plug weights .76oz before drilling the center hole, so removing 1 freeze plug and replacing it with a spacer is equal to 1/3oz savings, going with Titanium or aluminum will yield an even larger savings. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Reserved for results In its current configuration, 1 ss blast chamber and 15 freeze plug baffles with aluminum ends came in weighing more than I expected with the Titanium tube 21.8oz or 1lb 5.8oz. I looked at removing a few baffles and replacing with spacers, but the spacer material weighs over twice then the baffles so there would be no weight savings. <a href="http://s296.photobucket.com/user/WeberSteve/media/299AB9AC-C3E0-41D4-B97F-CCC84B4CD9AC_zpsek8mcfmd.jpg.html" target="_blank">http://i296.photobucket.com/albums/mm198/WeberSteve/299AB9AC-C3E0-41D4-B97F-CCC84B4CD9AC_zpsek8mcfmd.jpg</a> <a href="http://s296.photobucket.com/user/WeberSteve/media/5AAD4AE7-5D03-40E7-AADD-DF1512F038A9_zpss64m8n0y.jpg.html" target="_blank">http://i296.photobucket.com/albums/mm198/WeberSteve/5AAD4AE7-5D03-40E7-AADD-DF1512F038A9_zpss64m8n0y.jpg</a> Steel spacers (.05" thick) weight almost half the weight of a freeze plug for the same length taken up. Each freeze plug weights .76oz before drilling the center hole, so removing 1 freeze plug and replacing it with a spacer is equal to 1/3oz savings, going with Titanium or aluminum will yield an even larger savings. SS spacer material weighs 1.5oz per width of the freeze plugs, that's double the weight of s freeze plug. I may need to go with a reduced wall thickness for spacer material to reduce the weight. I'm using the SS spacer material from SDTA. |

|

|

|

|

|

|

|

|

|

Quoted:

Quoted:

Going off of your pictures, it doesn't look like you are screwing the endcaps in all the way. They are, O ring is fully compressed. Do your endcaps not have the relief after the threads? Maybe your orings are a bit too big. I personally would want metal/metal contact when screwed on. |

|

|

|

Quoted:

Do your endcaps not have the relief after the threads? Maybe your orings are a bit too big. I personally would want metal/metal contact when screwed on. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Quoted:

Going off of your pictures, it doesn't look like you are screwing the endcaps in all the way. They are, O ring is fully compressed. Do your endcaps not have the relief after the threads? Maybe your orings are a bit too big. I personally would want metal/metal contact when screwed on. Not sure on the relief, but no metal to metal, oring is compressed in between. Same orings from the other thread. |

|

|

|

|

|

When you get home, take out a freeze plug, and screw them on all teh way. The orings should go right into the tube, I see you painted them so that might make it a bit more difficult, but those orings should slip right inside. (unless you get them wet with oil, they suck it up and expand)

|

|

|

|

The endcaps should screw in all the way, flush if that is the right wording. As it sits now you either are not tightening them enough, the orings will squish in(dab of oil on them) or the innards of your can are to long.

Empty the can, remove the orings, if the caps screw in all the way then your gtg and need to adjust the innards or ask your hubby to screw the ends on, if not something is fuky. |

|

|

|

|

|

Quoted:

Quoted:

Quoted:

Quoted:

Nice, how much does it weigh? I updated the results post to show the weight. I will get the overall length tonight. Can you estimate what the weight of the build would be with the Ti tube instead of the carbon steel? I'm waffling between spending the extra money on the Ti or dealing with some extra ounces on the carbon steel. I'm using the Ti tube. Sorry, missed that. I thought you were using a steel one. |

|

|

|

I tried to install new orings on the end caps and screw them on. They still did not slip into the tube and only compressed, to the point that they would not come off, and I had to secure the tube in the vice and use a wrench to get the cap back off.

I called SDTA and they do not recommend using an o-ring and do not use them in their builds. So, I will be removing them from mine and adjusting the spacer accordingly. |

|

|

|

|

|

I was able to find some thinner wall spacer material that weighs less than the freeze plug baffles. I think I got the wrong size from them.

|

|

|

|

The spacer material that SD sells is not very friendly. Its VERY THICK and heavy. It reduces the ID and thus kills the internal volume while adding unnecessary weight. Its not BAD....but there way better options. If you need spacer material turned down, just let me know. I can help you out with that.

|

|

|

|

Quoted:

SS spacer material weighs 1.5oz per width of the freeze plugs, that's double the weight of s freeze plug. I may need to go with a reduced wall thickness for spacer material to reduce the weight. I'm using the SS spacer material from SDTA. View Quote Yup. One way for you to save weight is to start drilling weight reduction holes all over the spacers and FP walls. Or just go with Ti spacers. http://i296.photobucket.com/albums/mm198/WeberSteve/CF91D963-14FA-47A8-9FE7-F2C5420C31AB_zpsyk1t6vpw.jpg Your endcap looks normal, and just like mine. In theory your o-ring problem isn't that bad as long as you torque your encaps enough AND have all the threads in. But I agree with others that it should be tucked inside the tubes. It isn't meant to show like that. I would start grinding those a spacer down slowly and torque it all the way in. The o-rings are actually slightly over sized. So it may look like it is pinching, but it will slip in as your force it. BTW, those are NICELY done cones. Good job. |

|

|

|

Quoted:

The spacer material that SD sells is not very friendly. Its VERY THICK and heavy. It reduces the ID and thus kills the internal volume while adding unnecessary weight. Its not BAD....but there way better options. If you need spacer material turned down, just let me know. I can help you out with that. View Quote You could use aluminim tube as spacer material, couldn't you? SD only sells PVC and stainless in the D-tube size, but doesn't recommend PVC for anything other than .22 builds. I would think an aluminum spacer would be fine in a carbon steel tube, if you can find it in the appropriate size. |

|

|

|

Quoted:

You could use aluminim tube as spacer material, couldn't you? SD only sells PVC and stainless in the D-tube size, but doesn't recommend PVC for anything other than .22 builds. I would think an aluminum spacer would be fine in a carbon steel tube, if you can find it in the appropriate size. View Quote Absolutely.....the tube doesn't need any more strength. Aluminum spacer saves weight and can increase volume if you get the right stuff. I like the 1.375" OD .065" wall. Even turned down to 1.350" it makes an excellent spacer in the Apogee and or SD tubes. |

|

|

|

Quoted:

You could use aluminim tube as spacer material, couldn't you? SD only sells PVC and stainless in the D-tube size, but doesn't recommend PVC for anything other than .22 builds. I would think an aluminum spacer would be fine in a carbon steel tube, if you can find it in the appropriate size. View Quote View All Quotes View All Quotes Quoted:

Quoted:

The spacer material that SD sells is not very friendly. Its VERY THICK and heavy. It reduces the ID and thus kills the internal volume while adding unnecessary weight. Its not BAD....but there way better options. If you need spacer material turned down, just let me know. I can help you out with that. You could use aluminim tube as spacer material, couldn't you? SD only sells PVC and stainless in the D-tube size, but doesn't recommend PVC for anything other than .22 builds. I would think an aluminum spacer would be fine in a carbon steel tube, if you can find it in the appropriate size. The spacer material I have linked works perfectly, and keeps weight down. |

|

|

|

Quoted:

The spacer material I have linked works perfectly, and keeps weight down. View Quote Yes it does.....that is perfect. I wasn't saying the aluminum is preferred to the TI you listed, just that it was acceptable as far as strength goes. I used aluminum in the last couple tubes because I had it on hand, however if I had my choice it would be TI every time. |

|

|

|

Quoted:

Yes it does.....that is perfect. I wasn't saying the aluminum is preferred to the TI you listed, just that it was acceptable as far as strength goes. I used aluminum in the last couple tubes because I had it on hand, however if I had my choice it would be TI every time. View Quote View All Quotes View All Quotes Quoted:

Quoted:

The spacer material I have linked works perfectly, and keeps weight down. Yes it does.....that is perfect. I wasn't saying the aluminum is preferred to the TI you listed, just that it was acceptable as far as strength goes. I used aluminum in the last couple tubes because I had it on hand, however if I had my choice it would be TI every time. I guess my point is, is that I would want the stronger stuff in the blast chamber, and if you get it for that, you have a lot extra for the spacers. No need to over think it |

|

|

|

Quoted:

I guess my point is, is that I would want the stronger stuff in the blast chamber, and if you get it for that, you have a lot extra for the spacers. No need to over think it View Quote View All Quotes View All Quotes Quoted:

Quoted:

Quoted:

The spacer material I have linked works perfectly, and keeps weight down. Yes it does.....that is perfect. I wasn't saying the aluminum is preferred to the TI you listed, just that it was acceptable as far as strength goes. I used aluminum in the last couple tubes because I had it on hand, however if I had my choice it would be TI every time. I guess my point is, is that I would want the stronger stuff in the blast chamber, and if you get it for that, you have a lot extra for the spacers. No need to over think it Are you talking about this link? That's stainless, not Ti. |

|

|

|

The Ti will be 2-3x as much, and will make the suppressor heat up even faster

|

|

|

|

Quoted:

Awesome write up. I've got to try this View Quote He wasnt lying about thinking he was about to break his vice. I just tried forming a freeze plug and bent my vice handle. I'm gunna build a simple rectangular press frame for a bottle jack tomorrow. I'll some pics if it's ok with the op, and you guys wanna see it. |

|

|

|

Quoted:

He want lying about thinking he was about to break his vice. I just tried forming a freeze plug and bent my vice handle. I'm gunna build a simple rectangular press frame for a bottle jack tomorrow. I'll some pics if it's ok with the op, and you guys wanna see it. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Awesome write up. I've got to try this He want lying about thinking he was about to break his vice. I just tried forming a freeze plug and bent my vice handle. I'm gunna build a simple rectangular press frame for a bottle jack tomorrow. I'll some pics if it's ok with the op, and you guys wanna see it. Sure. |

|

|

|

Didn't work, my homemade press borked up the holes on the freeze plugs, couldn't keep everything centered. Got one that turned out pretty good and the proceeded to get it stuck in the sd tube after messing up the threads. So I've got a bunch of borked up freeze plugs, and a trashed tube. I'm going to cut and crush all the bad parts and wait till I can get a jig like the ebay one. If anyone has a line on one send me a pm.

|

|

|

|

Quoted:

Didn't work, my homemade press borked up the holes on the freeze plugs, couldn't keep everything centered. Got one that turned out pretty good and the proceeded to get it stuck in the sd tube after messing up the threads. So I've got a bunch of borked up freeze plugs, and a trashed tube. I'm going to cut and crush all the bad parts and wait till I can get a jig like the ebay one. If anyone has a line on one send me a pm. View Quote Send the guy on eBay a message, tell him I sent you. Ask for a good deal and tell him your situation that you tried. |

|

|

|

Quoted:

Send the guy on eBay a message, tell him I sent you. Ask for a good deal and tell him your situation that you tried. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Didn't work, my homemade press borked up the holes on the freeze plugs, couldn't keep everything centered. Got one that turned out pretty good and the proceeded to get it stuck in the sd tube after messing up the threads. So I've got a bunch of borked up freeze plugs, and a trashed tube. I'm going to cut and crush all the bad parts and wait till I can get a jig like the ebay one. If anyone has a line on one send me a pm. Send the guy on eBay a message, tell him I sent you. Ask for a good deal and tell him your situation that you tried. Done, thanks. |

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.