Greetings group,

Today I am here to discuss the construction of a cross draft spray booth I designed and built (Jan, 2015), to provide insight for anyone looking to build their own custom spray booth. As always safety is the highest priority. In this case for the required air flow needed to safely inhabit the work space, as well as the air flow required to safely achieve a diluted flammable solvent mixture. This was a very fun project, and only took about 3 days to assemble. However, a solid 2 weeks of research was conducted to ensure all of the components were compatible and would achieve the desired performance.

Details:

Size: 6.5’Wx7’Dx8’H

Volume: 364cu.ft.

Exhaust Fan: 10” Phresh Hyper Fan Shielded Digital Control

Fan Max CFM: 1,065 CFM

Air Exchange Rate @ Max CFM: .34 seconds

Air Exchanges Per. Hour @ Max CFM: 175.5

Air Exchanges Per. Minute @ Max CFM: 2.9

Air Exchanges Rate @ 33%: 57.9 seconds (<1 min.)

Required CFM for Diluted Solvent Concentration (<25% of LFL, using 100fps Calculation): 233CFM

Required CFM%: .219% of Max Available CFM

Illumination: (2) Dual 36’ Fluorescent Lights

Frame Construction: 2x4 Steel Stud

Flooring: .750” Plywood

Wrap: 5mil Poly

Intake Bank Filters: (2) 14”x24” 3M (4.67 cu.ft.)

Exhaust Bank Filters: (1) 14”x24” 3M (2.33 cu.ft.)

Access Door: 36” Standard Storm Door

Electrical Requirement: 110v-120v A/C

Total Cost: ~$750

After I had settled on the components needed I acquired the framing materials from my local hardware store (Home Depot). The remaining components (fan, control box, PID, lights, and switches) were all ordered. With parts on order, It was time to begin the erecting the frame work. The frame was constructed using standard 2x4 steel framing studs. I framed the unit with (3) filter banks, (1) Door, (1) Window, and a reinforced cross member along the roof for hanging parts. The flooring is traditional ¾” plywood.

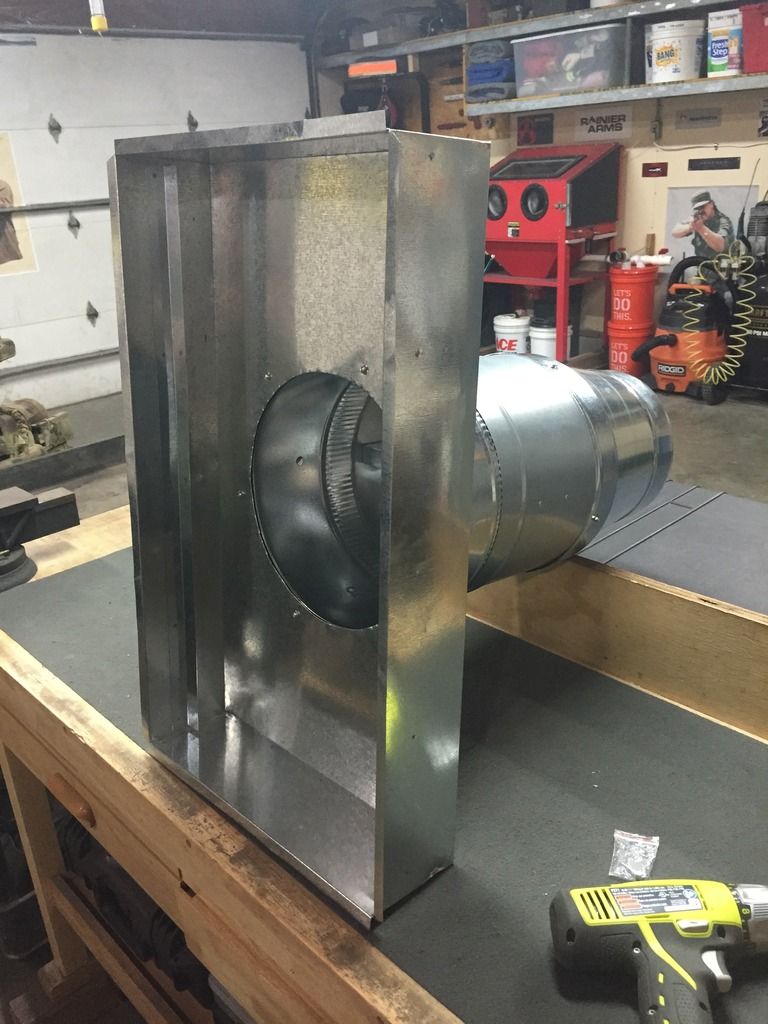

Once the initial frame work had begun I installed a filter bank that housed the fan and filter assembly. Here you can see I mocked it up with an older fan while the Hyper Fan was on order.

Next on the list was to build and install the control box, and illumination. The main box individually controls the lighting, main power, fan, and also has a temperature readout. Once installed, the entire unit was wired up with Romex 14/3 cable, thermometer, and power cord.

Next on the list was wrapping the exterior of the unit, and to finish fabrication of the window. The wrap is 5mil poly held in place with thin fiber strips, and self-tapping screws. Final mounting of the intake filter banks and control box was conducted as well. A full system test was conducted.

Final assembly included hanging of the door, mounting the exterior vent, and connecting the ventilation ducting. Once full assembled, a final check was conducted.

To date I have over 75 hours of run time on this spray booth. It has been a phenomenal unit, and helped me produce some beautiful finishes. I have changed the exhaust bank filter two times, and there is no sign of residual coating found inside the ventilation ducting. Moreover, my first run I covered the vent with a white pillow case, and there was no evidence that nay coating had escaped past the filter bank. I have used Cerakote and various aerosol spray paints in this booth.

Thanks for looking, and I hope this helps others in their quest for a DIY spray booth.

Win a FREE Membership!

Win a FREE Membership!