To begin this, I have attempted an 80% receiver, purchased with the jig from TR Enabling, and it failed. The aluminum split inside the fire control pocket into where the magazine release is.

I ordered everything possible from 80% Arms, in order to keep it uniform, I am using their Black Anodized 80% lower, their universal jig, and their bit set. I ordered the items 2 weeks ago, and they arrived today. On to the pictures!

The Anodized 80% lower. To note, there are 3 very small scratches on the anodizing on the left side of the lower.

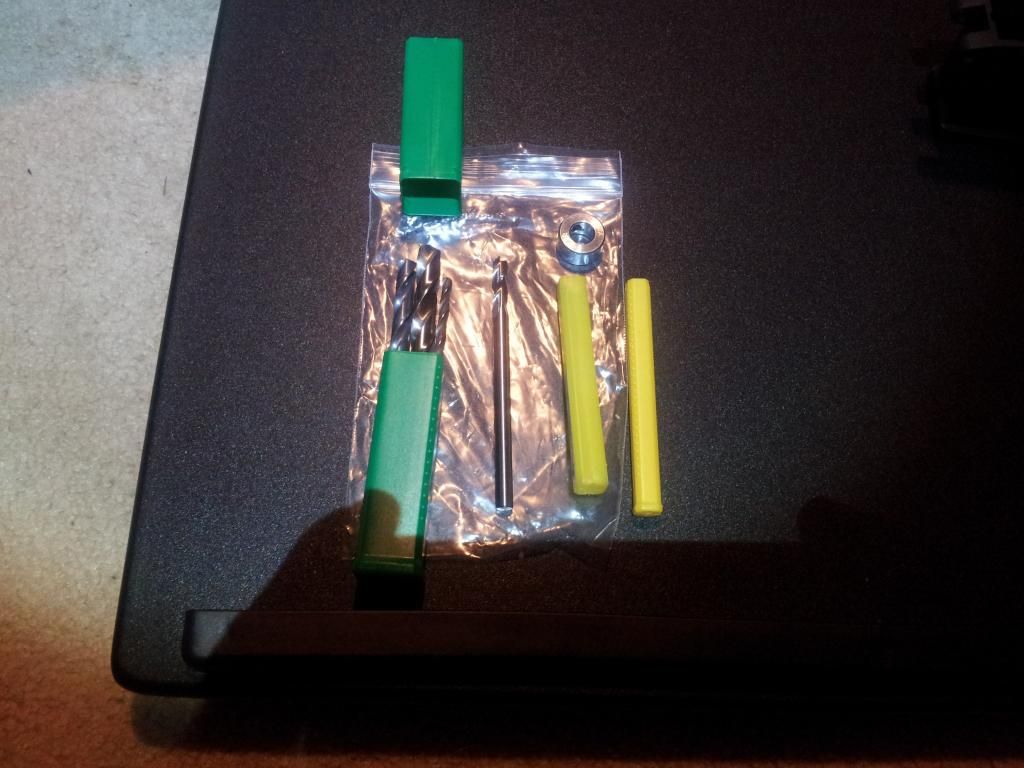

All of the drill bits needed, the end mill, and the drill stop. Wrapped up nicely and seems good quality.

The entire jig in its packaging. Router base on top.

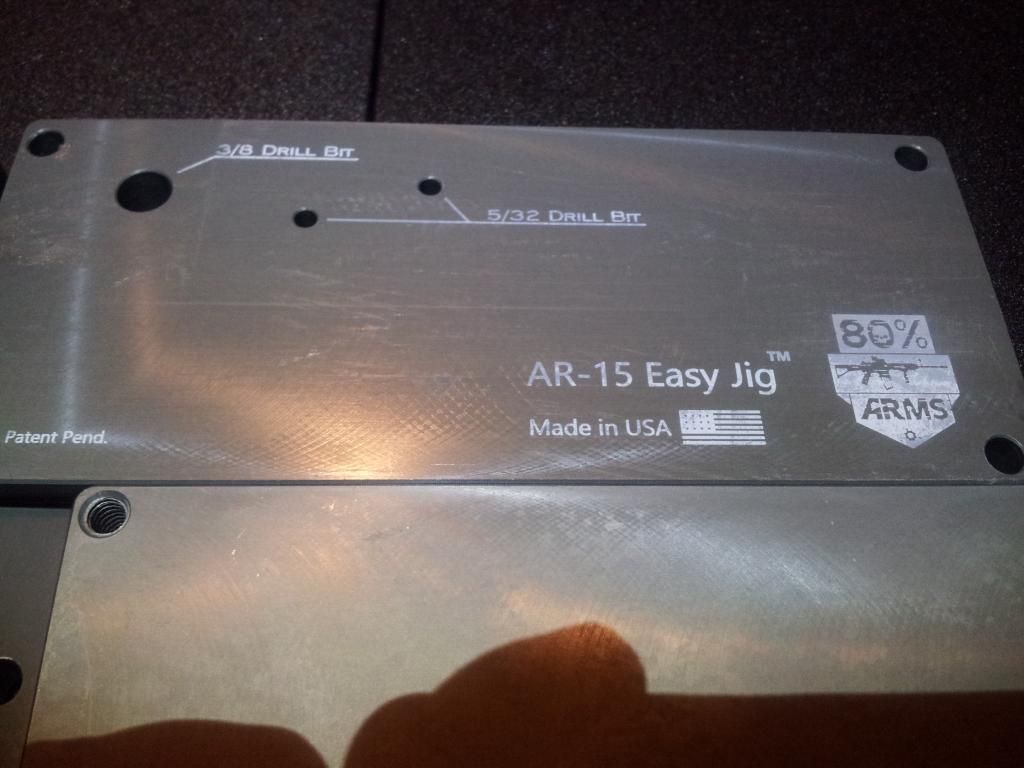

The side view of a wall of the universal jig, with the logo.

The bottom of the router base has several rough patches, and although it won't hinder how I machine it since it isn't touched, it doesn't look very nice.

This is the entire jig laid out.

This is everything I ordered from 80% arms, and a brief review on them.

I will update this thread once I turn it into a stripped lower, and maybe continue until the rifle is complete. Thanks for reading!

Win a FREE Membership!

Win a FREE Membership!