Quoted:

I understand the two metals, I was just trying to figure out the offset on the wrench and the thinking behind it. If I set the torque wrench to 50 ft/lbs i'm not getting that on the barrel nut, so why shit over +/- 10-15 ft/lbs? Or maybe you have it figured out when you do torque the barrel nut?

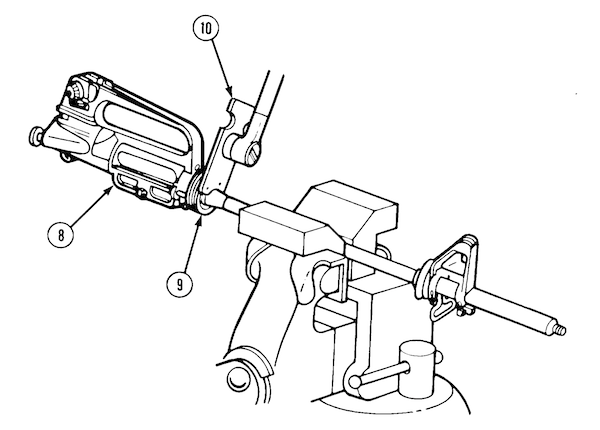

THERE IS NO OFFSET. You install the barrel nut wrench IN LINE with the torque wrench, just like in the pictures in the TM. It's on page 3-41 of the manual (the 155th page in the document), which you can conveniently find

HERE. Here's the picture:

No calculations, no worries. "At least 30 ft/lb, but no more than 80 ft/lb" is the spec, measured with the barrel nut wrench in line with the torque wrench. That's all you need to worry about - getting those numbers with the wrenches lined up together.

Win a FREE Membership!

Win a FREE Membership!