|

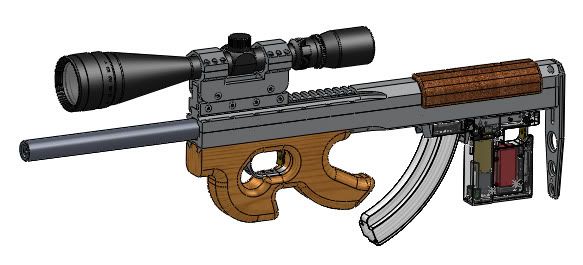

After a little more tweaking and the fact that Armalite still sells AR180 parts at decent prices, i think i'm gonna go ahead and pick up a carrier, guide rods, springs, bolt catch, and a few other small parts and try to use that as a starting point. Then i'll at least actually have some good parts in hand to measure...

The piston will be interesting, and i'll be redesigning the op-rod setup to use 2 oprods, and a single piston, and a modified AR15 bolt, since the cam pin hole is 90deg off of an AR180 pin hole allowing for an upwards extraction... should be interesting... |

|

|

|

Quoted:

Quoted:

http://www.ar15.com/archive/topic.html?b=3&f=4&t=426271

Quoted:

+1

Do you have a website of your projects? I'd follow your blog. I would like to see how he did his AR in his profile pic. not sure if you can see the archives... Thanks! Might be the excuse I need to finally become a team member... |

|

|

|

Quoted:

Quoted:

http://www.ar15.com/archive/topic.html?b=3&f=4&t=426271

Quoted:

+1

Do you have a website of your projects? I'd follow your blog. I would like to see how he did his AR in his profile pic. not sure if you can see the archives... Very interesting (both the pistol without the buffer tube, and the PDW). |

|

|

|

Very cool, project. I look forward to following it to completion!

|

|

|

|

Just ordered a YHM 1:7 16" carbine barrel and a bunch of AR180B parts from Armalite to play with.

This could get interesting soon... |

|

|

|

I'm following this project.

I can't wait to see what you come up with. |

|

|

|

Quoted:

Just ordered a YHM 1:7 16" carbine barrel and a bunch of AR180B parts from Armalite to play with. This could get interesting soon... Have you done any of the external prototyping yet? |

|

|

|

Quoted: Other than some modeling, noQuoted: Have you done any of the external prototyping yet?Just ordered a YHM 1:7 16" carbine barrel and a bunch of AR180B parts from Armalite to play with. This could get interesting soon... I'll get all the innards laid out before i waste a $150 chunk of plastic or a $50 chunk of aluminum |

|

|

|

|

|

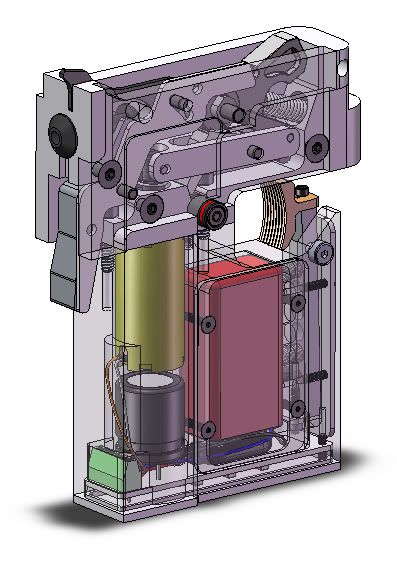

Quoted:

http://i241.photobucket.com/albums/ff206/devtucker/Concepts/pdrassembly1.jpg Managed to slim it down to 1.5" except for the front section. This is showing some of the AR-180 parts. Should have some more time to work on the design this coming week... Looks great! Have you thought about how you're going to activate the trigger yet? |

|

|

|

Quoted: Looks great! Have you thought about how you're going to activate the trigger yet? Will most likely be a pull-linkage instead of the usual push linkage found in bullpups, though i would like to move the sear forward and do something like the RFB for a much better trigger, but i'm not sure i could package that and have it be very robust in such a small package... |

|

|

|

Looking good so far!! I Can't wait till you tear into this thing.

|

|

|

|

Quoted:

Quoted:

Looks great! Have you thought about how you're going to activate the trigger yet? Will most likely be a pull-linkage instead of the usual push linkage found in bullpups, though i would like to move the sear forward and do something like the RFB for a much better trigger, but i'm not sure i could package that and have it be very robust in such a small package... Maybe mill a long chunk of aluminum (1" wide by 1.25" high, by however long, should be plenty) to take an AR trigger group mounted at the front of the chunk, but modify the hammer by cutting the upper half off and connecting it (by a link rod) to a hammer at the rear of the aluminum chunk? Hollow out the aluminum chunk to keep it light, and drop it into your Nylon frame/housing. ETA: The modified hammer at the front (trigger group hammer) would have the hammer spring, and the rear hammer would just be on a hammer pin and controlled by the hammer link rod. |

|

|

|

Quoted: Quoted: Quoted: Looks great! Have you thought about how you're going to activate the trigger yet? Will most likely be a pull-linkage instead of the usual push linkage found in bullpups, though i would like to move the sear forward and do something like the RFB for a much better trigger, but i'm not sure i could package that and have it be very robust in such a small package... Maybe mill a long chunk of aluminum (1" wide by 1.25" high, by however long, should be plenty) to take an AR trigger group mounted at the front of the chunk, but modify the hammer by cutting the upper half off and connecting it (by a link rod) to a hammer at the rear of the aluminum chunk? Hollow out the aluminum chunk to keep it light, and drop it into your Nylon frame/housing. That was more or less the plan when i was thinking about a front-sear design, but the trigger is so close to the bottom of the barrel, that it wouldn't fit an AR style trigger/hammer in such a short vertical space. But the aluminum "spine" is still on the table. Right now i've got a couple chunks of 1.75" and 2" square 6061 stock sitting on the table... |

|

|

|

Using the barrel as the spine like in your diagram would probably be lighter. Why is the hammer too high? It looks like you have plenty of vertical space in the rear of your stock.

|

|

|

|

Quoted:

Quoted:

Quoted:

Quoted:

Looks great! Have you thought about how you're going to activate the trigger yet? Will most likely be a pull-linkage instead of the usual push linkage found in bullpups, though i would like to move the sear forward and do something like the RFB for a much better trigger, but i'm not sure i could package that and have it be very robust in such a small package... Maybe mill a long chunk of aluminum (1" wide by 1.25" high, by however long, should be plenty) to take an AR trigger group mounted at the front of the chunk, but modify the hammer by cutting the upper half off and connecting it (by a link rod) to a hammer at the rear of the aluminum chunk? Hollow out the aluminum chunk to keep it light, and drop it into your Nylon frame/housing. That was more or less the plan when i was thinking about a front-sear design, but the trigger is so close to the bottom of the barrel, that it wouldn't fit an AR style trigger/hammer in such a short vertical space. But the aluminum "spine" is still on the table. Right now i've got a couple chunks of 1.75" and 2" square 6061 stock sitting on the table... Take a look at a standard AR hammer. With the hammer face vertical and looking at it from the side, the point that the disconnector catches is the highest part that would have to be left on the modified trigger group hammer. The hammer link rod could be attached forward of that (drill a hole just below where you cut the hammer off, and insert the bent end of the hammer link rod) and routed back so that it runs beside the disconnector. Would that fit under the barrel? |

|

|

|

Quoted:

Using the barrel as the spine like in your diagram would probably be lighter. Why is the hammer too high? It looks like you have plenty of vertical space in the rear of your stock. The clearance issue with the hammer, would be with the forward hammer, if an AR trigger group is mounted under the barrel (in the normal location in relation to the pistol grip) with a linkage rod running from the trigger group's hammer back to a hammer that is mounted behind the bolt. The rear hammer hits the firing pin and the bolt pushes it back to cock the action when the bolt cycles. The front hammer takes care of the trigger/sear function and keeps the trigger from having the mushy feel that is typical of bullpups (which normally have only one hammer and the sear in the rear of the stock). |

|

|

|

Quoted: Using the barrel as the spine like in your diagram would probably be lighter. Why is the hammer too high? It looks like you have plenty of vertical space in the rear of your stock. Planning on the barrel and upper being rigidly attached, with a drop-in fire control module in the lower that includes the FCG and upper magwell, and maybe some inserts for the trigger/selector/mag release But yes, the current plan is to move the sear to the back like a standard bullpup, but the clearance issues would be if it were located in front of the grip below the barrel. |

|

|

|

|

|

Quoted:

Here's the standard AR trigger-hammer pin locations relative to the grip. Yeahhh, it's kinda tight in there... Looks like the gas block would be more of a clearance problem than the barrel. A forward trigger group would provide a better feeling trigger, and simplify the design of the safety, but it looks like you don't have the space. |

|

|

|

Trigger area would be tight, but the hammer would relocate to the rear, right?

|

|

|

|

Quoted: Trigger area would be tight, but the hammer would relocate to the rear, right? Right. |

|

|

|

there's a guy over on RimfireCentral doing some eTrigger work...check it out

of course he's packaging it so it will work with the majority of 10/22 stocks, but it's just solenoids and a battery. I'm sure you could relocate/repackage to better suit your needs

maybe you could snag a little inspiration from him http://www.rimfirecentral.com/forums/showthread.php?t=317395 |

|

|

|

Quoted: Thanks, yeah i've seen his work before and i'm sure it's great for a target gun, but i'm of the "too much to go wrong" opinion on that one...there's a guy over on RimfireCentral doing some eTrigger work...check it out http://i611.photobucket.com/albums/tt194/BulZiPhoto/p90styleforegrip.jpg http://i611.photobucket.com/albums/tt194/BulZiPhoto/jhsbp.jpg of course he's packaging it so it will work with the majority of 10/22 stocks, but it's just solenoids and a battery. I'm sure you could relocate/repackage to better suit your needs http://i611.photobucket.com/albums/tt194/BulZiPhoto/etrigger.jpg maybe you could snag a little inspiration from him http://www.rimfirecentral.com/forums/showthread.php?t=317395 |

|

|

|

Instead of using a 16" barrel, why not use the barrel length that you want and pin on a barrel shroud extension. That way you can build it the way you want and have the gas system set up correctly in the beginning.

|

|

|

|

Quoted: Instead of using a 16" barrel, why not use the barrel length that you want and pin on a barrel shroud extension. That way you can build it the way you want and have the gas system set up correctly in the beginning. The tuning going from a 16" to an 11.5" won't be all that difficult, and i've already got a YHM 16" carbine 1:7 barrel. Even at 16", the OAL will be under 26" without a long flash hider... Unfortunately, the AR180 gas port/shoulder distance is about 1/4" longer than on an AR-15 barrel, so i either have to make a new gas block or turn the shoulder on the barrel back a bit, and i'm inclined to go with modifying the barrel, since the AR180 gas block is smaller and lighter than anything i can make on my bridgeport... plus i already have one in hand... Once i get it running, I'll probably send this barrel off to ADCO to have it shortened after the SBR stamp is back. |

|

|

|

|

|

Quoted:

Quoted:

Here's the standard AR trigger-hammer pin locations relative to the grip. Yeahhh, it's kinda tight in there... Looks like the gas block would be more of a clearance problem than the barrel. A forward trigger group would provide a better feeling trigger, and simplify the design of the safety, but it looks like you don't have the space. I guess since the YHM bbl has already been ordered it is too late to back out of a 7" gas port. I would wonder about moving the gas block either rearward into a pistol length gas system or forward into a midlength system. If you moved it back the barrel itself could be turned down to a lightweight profile at least at the area near the trigger group. I would just be concerned with having too much pressure initially before having a chance to SBR it. Then again, you could always use a pistol cartridge blow-back operation and chamber it in 7.62Tok |

|

|

|

PDR = Personal Defense Rifle (rifle cartridge).

Blowback with a Tok takes out the design challenges, too easy As far as the barrel, i kinda wanted to start with existing barrels for cost reasons, and the SBR barrel will be ~11.5" so midlength is a bit long and pistol is too short... It will probably take some tuning, but once i SBR it, i will probably throw on a Gemtech TREK which will only add about 4" to the PDR and cuts out ~32 db...

|

|

|

|

Quoted:

PDR = Personal Defense Rifle (rifle cartridge). Blowback with a Tok takes out the design challenges, too easy As far as the barrel, i kinda wanted to start with existing barrels for cost reasons, and the SBR barrel will be ~11.5" so midlength is a bit long and pistol is too short... It will probably take some tuning, but once i SBR it, i will probably throw on a Gemtech TREK which will only add about 4" to the PDR and cuts out ~32 db... Would the can add some pressure to make a middy work better? However you do it, judging by the gun in your avatar, I am sure it will be bad ass. |

|

|

|

Quoted: Quoted: PDR = Personal Defense Rifle (rifle cartridge). Blowback with a Tok takes out the design challenges, too easy As far as the barrel, i kinda wanted to start with existing barrels for cost reasons, and the SBR barrel will be ~11.5" so midlength is a bit long and pistol is too short... It will probably take some tuning, but once i SBR it, i will probably throw on a Gemtech TREK which will only add about 4" to the PDR and cuts out ~32 db... Would the can add some pressure to make a middy work better? However you do it, judging by the gun in your avatar, I am sure it will be bad ass. Probably, but i would like to be able to run it unsuppressed with a Levang comp or similar for minimum overall length.. I MIGHT be able to get it to run reliably with a middy. It will be a piston gun using the AR180B piston.

|

|

|

|

Quoted:

Then again, you could always use a pistol cartridge blow-back operation and chamber it in 7.62Tok Why blowback? 7.62Tok will cycle a pistol length DI gas system on a 16" barrel. If you dump the weights out of the buffer, it'll cycle on a 10" barrel. |

|

|

|

Quoted:

Quoted:

Quoted:

PDR = Personal Defense Rifle (rifle cartridge). Blowback with a Tok takes out the design challenges, too easy As far as the barrel, i kinda wanted to start with existing barrels for cost reasons, and the SBR barrel will be ~11.5" so midlength is a bit long and pistol is too short... It will probably take some tuning, but once i SBR it, i will probably throw on a Gemtech TREK which will only add about 4" to the PDR and cuts out ~32 db... Would the can add some pressure to make a middy work better? However you do it, judging by the gun in your avatar, I am sure it will be bad ass. Probably, but i would like to be able to run it unsuppressed with a Levang comp or similar for minimum overall length.. I MIGHT be able to get it to run reliably with a middy. It will be a piston gun using the AR180B piston. If I'm not mistaken, one of the dealers selling barrels is selling a 16" barrel with a rifle length gas system (very little barrel left in front of the gas block). I don't know if those barrels require anything more than a larger gas port to function reliably. ETA: It's a DPMS 16" heavy barrel with a rifle length gas system. Midway lists it as item # 724394. From the reviews, it apparently doesn't cause any cycling problems. |

|

|

|

Yeah, i've seen rifle-length 16" barrels and i have a carbine-length 10.0" barrel on the pistol in my avatar, but how much barrel is left on a midlength 11.5" barrel? I forget what the midlength port position is off the top of my head... On my pistol, the vortex laps over the barrel about 0.05" and i cut the shoulder so that it bottoms on the shoulder only about .002-.003" before bottoming on the gas block, so it doesn't get much shorter than that... |

|

|

|

Quoted:

[div style='font-size: 8pt; font-family: Verdana, Arial, Helvetica; background-color: rgb(213, 212, 213); ']Yeah, i've seen rifle-length 16" barrels and i have a carbine-length 10.0" barrel on the pistol in my avatar, but how much barrel is left on a midlength 11.5" barrel? Taking a rough measurement off of my 18" midlength upper, a midlength 11.5" barrel would put the gas port about 2" from the end of the barrel. |

|

|

|

I happened to think of the gas tubes in my parts bin.

A midlength gas tube is 2" longer than a carbine gas tube. |

|

|

|

Carbine is 7", Middy is 9", and Rifle is 12".

I am curious to know if the suppressor would increase the pressure enough to make a middy more feasible than the carbine. ETA: I didn't see your response to mine earlier, though I am phrasing the question as purely theoretical now. Nothing saying you can't run the barrel out an inch or so more to make sure you have the clearance for a mount/brake as well. ETA: How long is your gas block going to be? |

|

|

|

Quoted: Carbine is 7", Middy is 9", and Rifle is 12". I am curious to know if the suppressor would increase the pressure enough to make a middy more feasible than the carbine. ETA: I didn't see your response to mine earlier, though I am phrasing the question as purely theoretical now. Nothing saying you can't run the barrel out an inch or so more to make sure you have the clearance for a mount/brake as well. ETA: How long is your gas block going to be? Gas block is only 0.7" long, and i'll be turning the gas block shoulder on the barrel back 0.22" so that the gas port lines up. So yes, a middy would fit, but i'd be concerned with reliability as i'm in unknown territory on the AR180 piston and bolt, and the dual oprod/yoke that i've got drawn up will have a bit more mass than the AR180 op-rod. |

|

|

|

Quoted:

Quoted:

Carbine is 7", Middy is 9", and Rifle is 12". I am curious to know if the suppressor would increase the pressure enough to make a middy more feasible than the carbine. ETA: I didn't see your response to mine earlier, though I am phrasing the question as purely theoretical now. Nothing saying you can't run the barrel out an inch or so more to make sure you have the clearance for a mount/brake as well. ETA: How long is your gas block going to be? Gas block is only 0.7" long, and i'll be turning the gas block shoulder on the barrel back 0.22" so that the gas port lines up. So yes, a middy would fit, but i'd be concerned with reliability as i'm in unknown territory on the AR180 piston and bolt, and the dual oprod/yoke that i've got drawn up will have a bit more mass than the AR180 op-rod. Opening the gas port to a larger size will make a difference. As I recall, my 7.62Tok barrels have the gas ports opened up to 0.120". |

|

|

|

Will you have a way of metering the pressure to the system?

I am unfamiliar with the AR180 and the piston system on it. If you had a trash bbl that you didn't mind messing up, you could always drill new ports and weld over the old ones until you found the optimum location then order a barrel with the gas-port drilled in the location you choose. |

|

|

|

Does anybody have a Levang comp they can measure? Length and diameter is all i really need... The one in my model was a best-guess as i don't have one...

Also, I wonder if the Gemtech Trek is right at 1.5" diameter as advertised or if it's a little over/under...

|

|

|

|

Quoted:

Does anybody have a Levang comp they can measure? Length and diameter is all i really need... The one in my model was a best-guess as i don't have one... Also, I wonder if the Gemtech Trek is right at 1.5" diameter as advertised or if it's a little over/under... The Levang is 1.995" in length and .918" in diameter. I am sure nominal is 2.000" x .920". |

|

|

|

If you would like a mid length gas tube in a carbine length, couldnt you get a pigtail gas tube and make it work? Or does a pigtail make a carbine change to rifle length?

|

|

|

|

Quoted: If you would like a mid length gas tube in a carbine length, couldnt you get a pigtail gas tube and make it work? Or does a pigtail make a carbine change to rifle length? I think i'm trying to go the opposite direction that you think i am... Plus it's piston operated... |

|

|

|

Quoted:

If you would like a mid length gas tube in a carbine length, couldnt you get a pigtail gas tube and make it work? Or does a pigtail make a carbine change to rifle length? This is going to be a piston gun, if I understand correctly, so gas tube length is irrelevant, except for port placement for the piston system. |

|

|

|

Duh me.....

I just got caught up in skimming over the gas tube convos and forgot you were going piston Im such a newb..... |

|

|

|

Concerning the electronic trigger mentioned earlier: didn't the ATF rule all e-triggers were illegal ( too easily converted to full auto)?

Following this thread with interest. buckmeister |

|

|

|

Quoted: If you would like a mid length gas tube in a carbine length, couldnt you get a pigtail gas tube and make it work? Or does a pigtail make a carbine change to rifle length? Pigtail gas tubes are a gimmick anyway. Making the gas tube longer doesn't change where the gas port is. |

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.