|

Posted: 7/4/2008 12:29:38 AM EDT

The ramping of 9mm bolts was discussed in another topic string re: "LOCKED UP", but thought it would be good to have a thread for ramped 9mm bolts and pictures of others ramped bolts.

Here is a photo of my ramped 9mm bolt -- Ramped by ADCO Firearms. Another board contributor indicated that this bolt is not ramped correctly -- just would like to see pictures of other ramped bolts and discussion on if this ramp is correct or if there is a better way to ramp. Comments on the bolt ramp??  BTW -- My 9mm RRA upper from ADCO works excellently -- currently using DPMS Hammer, Slash 9mm Q Buffer, Wolff XP buffer spring, 3/4" extractor roll pin, CProducts Mags and Colt Mags, Hahn "Permanent" block. Dave |

|

|

|

Go to m60joes website and you will see a correctly ramped bolt and that bolt you have in the pic is not ramped enough so it still slaps the hammer down to hard. Mike |

||

|

|

ADCO did mine the same way, and Ive never had an Issue with it in both Full-Auto and Semi-Auto. There is nothing wrong with the ramp job pictured. |

||

|

|

Like i said in my other post this is a correct ramp http://www.m60joe.com/ |

|||

|

|

|

MGP -- Thanks for the comment. Can you share how long the ramp is when ramped as you outline? The ADCO ramp is about an inch.

Dave |

|

|

|

I ramp them 1-1/4" TO 1-1/2" |

||

|

|

|

|

That is std "COLT" semi-auto by design... |

||

|

|

|

ADCO is a Top Quality vendor. I do not know anything about ramping a 9mm bolt, I do know that ADCO knows their struff. Have you asked Steve about this?

|

|

|

My first thought was kill that weenie dog, and feed him to my pit bull....... And for you Pit bull haters.. My pit bull has NEVER killed an ostrich...

|

That is a stock setup that after time will egg out your receiver and break hammer pins. |

||

|

|

well that explains the hammer pins walking out after a long shooting session |

|||

|

|

Not sure what you is saying, but knock the hammer pin out, see if it come out as 1 piece or 2.... hammer pin is actually held in place by the "J" hook up inside the hammer body --> look throught the hammer pin' hole on the hammer and see if the wire "J" hook still in there, and slide the pin in to see if it positively snap into place. This is the way COLT built the 9mm SMG when they brought it out, simply put it on a M16 lower and ran with it...  With recreation shooters blasting rounds faster than any LE round count, broken pins and hole wear more common, so Ken at SAWLESALES started to "ramp" the 9mm bolt mimmick that found on a M16 carrier.. This is the common approach to ramping -   Thus for semi-auto, we just use a nuetered M16 hammer, M16 selector set to semi operates as AR-15, so just loose the auto lug and run. With the long ramp, hammer reset is slower, "BUT" in 9mm full-auto, the bolt "MAY NOT" come back far enought o allow auto-sear to catch the lug on hammer (geometry thing with the tail end of the ramp), but mine has worked on COLT M16 factory lower, and 1 converted lower...  |

||||

|

|

+1 on ADCO. My bolt (pictured) and combination has (as I state in the original post) worked 100% without any problems and I have no complaints whatsoever. I am interested in the open discussion of how others do ramping and the merits of different approaches. If I had any complaint I would have taken it to ADCO directly w/o posting here. Dave |

||

|

|

|

I'm a little lost here... so even on a factory colt 6450, I should probably have the bolt ramped? What else should I have done to ensure that it functions without problems for a long time?

|

|

|

|

|

I mis spoke, the trigger group pins were walking out, it was early and i need ALOT of coffee

So ramping the bolt or buying a ramped bolt and changing the hammer will increase the life of the weapon and components? |

|

|

|

Mine is ramped, JP hammer "DPMS works just as good" with a set of Gen II KNS pins. |

||

|

|

It's fine the way it is. The "standard" ramp is cut @ 3 degrees. What you have looks like 6 degrees. Either way is better than factory. |

||

|

|

I think you have hit on the truth. The depth of cut increases the amount of elapse time over which the load is applied to the pin and thus would reduce shock loading and resulting fatigue, increasing the pin's life. Bottom line is the depth is by far the most important component although the angle of the ramp will have some influence once the hammer face is moving along it. Edit: I needed to do some better thinking re: free body diagrams and shear force. Comments? |

||

|

|

|

What everybody is not understanding is the length of the ramp is just as important as the depth.With a short ramp you are still slamming the hammer down and a longer ramp will gradually cock the hammer making it a lot less stressful on the hammer pin and receiver. Simple as that! Mike

|

|

|

|

|

Are RRA bolts ramped? I don't have my gun next to me...just wondering if I need to send mine off some where to get the work done?

|

|

|

I owned a Colt a for a month...and now I'm stuck with the name...

|

Nobody' bolts is ramped, as they is "COLT" spec. Ramping is an improvement originally made by Ken @ SAWLESALES. |

||

|

|

Depth and length of cut are equally important as far as I am concerned. I thought the object was to "ease" the hammer back as opposed to "slamming" it back with an unramped bolt carrier. While a "short" ramping, best shown by the OP, is better than nothing, I would certainly wish for a longer ramp. For a post-ban semi-auto I would chalk this up as a "live and learn" event. For a pre-ban semi-auto, I would run the bolt carrier while actively seeking a local means of elongating the ramp. I would not let that short-ramped bolt touch a full-auto receiver. - BG |

||

|

Student 1: "Mr. [BUCC_Guy], can you do a cart-wheel?"

Me: "I can do anything you want, and more." Student 2: "Except attract girls." |

This statement is somewhat silly isn't it? I mean, if you had never had your bolt ramped at all, it would still work just fine. It's what happens to the trigger pins and holes over an extended period of time, with a high enough round count, that seems to be the issue. This thread has finally explained bolt ramping in enough detail, and with enough reasoning, that I finally fully understand the purpose. |

|||

|

|

Let me see is 15000 rounds FA convincing enough? My lower looks new still, no damage what so ever. |

||||

|

|

Its still not ramped enough.The longer ramp is much easier on the gun period. |

|||||

|

|

|

"Hover Cover" UH-1E's & Beaucoupe 7.62

Semper Fidelis ~ It is not negotiable. It is not relative, but absolute. |

|

Has anyone actually calculated how much of the hammer rotation is during the time the hammer face is on the ramp. I suspect that the largest part of the total hammer rotation is before the hammer face ever touches the ramped surface -- it seems likely that only the last 5-8 degrees of hammer rotation is affected by the slope of the ramp. I may just have to calculate the amount. It seems like most of the hammer rotation would occur while the back side of the bolt slides up the hammer face as the bolt moves in recoil. I am sure that a shallower ramp would be smoother for this final hammer rotation however.

|

|

|

|

I disagree. If you have a ramp that is half as deep and and twice as long, you will be adding more sheer forces on your hammer pin, as compared to one that is deeper/shorter. If the length of ramp is so important (assuming the same depth of cut) why only ramp half the length of the bolt. Why not ramp all the way up to the end of the bolt? |

||

|

|

Which shallow ramp are you talking about? |

||

|

|

The ramp is just as deep but longer.If you cut the bolt that deep and run the ramp the length of the bolt you will not be able to cock the hammer. ETA: The longer ramp is much smoother. You can actually feel the difference when pulling back the charging handle to cock the hammer if that does not convince you i dont know what will.Rate of fire will also increase proving that it is easier to cock the hammer. |

|||

|

|

I'm sure that you could put 15,000 rds FA through an unramped bolt with no problems at all. Doesn't mean that it's not taking more of a beating, even if it shows no adverse wear. |

||||||

|

|

|

The depth of the ramp determines when the hammer cocks - how soon, with how much force. If you have a 9mm upper and a standard non ramped bolt, cycle it by hand while holding trigger and listen/feel for the reset - make note of how far back you had to move the bolt before it reset/cocked the hammer.

Now do the same with a ramped bolt, or 2 with 2 different angles. A semi auto 9mm, without a ramped bolt, will probably last a lifetime of use without damage to anything. Ramping the bolt just makes things easier. I would NOT want a non ramped bolt in an M16 that I had to pay for$$$$. We did the longer ramps at first, but found with the umpteen different brands of hammers available, which are different heights - not all would cock with the longer ramp. We shortened the angle a bit, and seem to have found a ramp that works with everything. I have the "shorter" ramp in my transferable M16, and after thousands of rounds -at 1100 rounds per minute, everything is just fine. 9mm M16 video |

|

|

I'm no good at telling people what they want to hear when I dont believe it myself :)

|

|

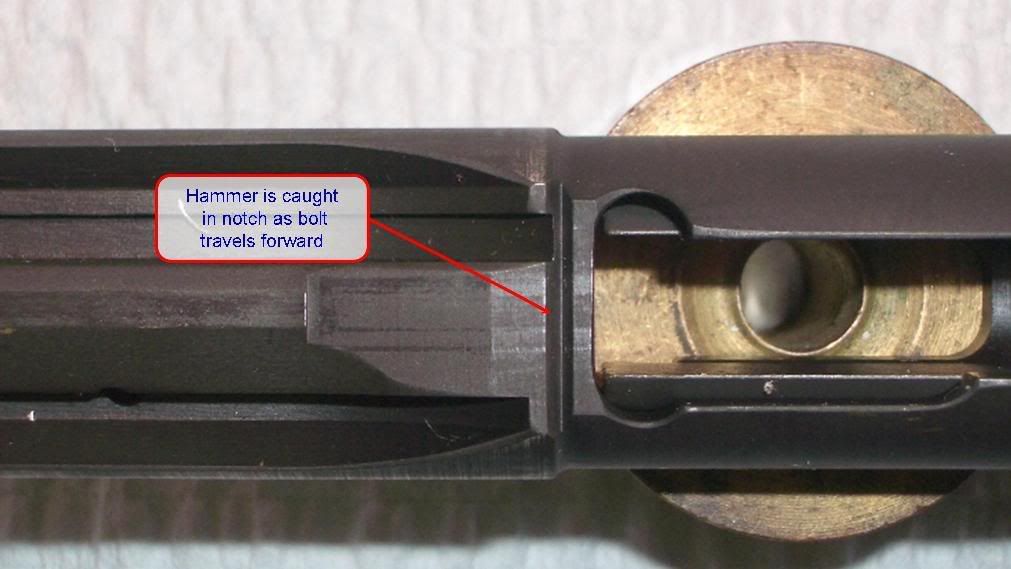

One reason for the ramp is to reduce the stress when hammer is cocked. The other is to eliminate the "locked up problem"

See pic below. As you can see , there is a knotch that catches some non 9mm hammers are the bolt goes forward. It locks up the gun so bad you need to push out both the pivot and takdown pin  After ramping this notch is eliminated  AS far as the angle and depth to reduce stress on your hammer pin there are obviously different opinions on the subject. I am far from being an expert so I took a less scientific approach I used a 5deg ramp ( because I had a 5 degree angle block for set up in my pile of mill tooling ) . Depth of ramp and length of ramp was similar to a M16 carrier I had. My reasoning was this. I am using a CMC trigger group since I use this lower on numerous uppers. Since I know this trigger group works fine with the ramp on the M16 carrier why wouldn't I just duplicate it ? Seemed like the logical approach If I were to do it again, I would reduce the length of the ramp as ADCO suggested. I have had the odd failure to cock the hammer with "light " loads |

|

|

|

Do you have a Colt 9mm bolt to measuer? I wonder if its any thicker than a RRA bolt?  We've had a few Colt 9mm owners buy 9mm RRA uppers with ramped bolts. The longer ramped RRA bolt would not cock any of the Colt 9mm hammers. Talk about a bitch - try finding a large pin M16 hammer to modify to work with a ramped bolt. We ended up every time swapping the longer amped bolts for the shorter ramped to get things to work. |

||

|

I'm no good at telling people what they want to hear when I dont believe it myself :)

|

You are correct. I was having a brain fart there. |

||

|

|

The Bolt you ramped for me was a Factory Colt and it runs flawless. |

|||

|

|

|

If you are looking for smooth hammer cocking, the bolt ramping is a vast improvement over the stock RRA bolt pattern. But, I believe no mater what you do (long ramp or short ramp - I went short ramp) you should also consider a light radius of the sharp edge on the hammer side of the ramp job.

I have a cheap digital camera but I believe the amount of radius is shown in the pictures. I asked the machinist to do the radius when he cut the ramp. I believe he did it with light milling, a diamond file, and various grades of wet/dry sand paper. It is subjective but bolt travel to reset the hammer is very, very smooth. I think smooth will add years to the pin holes. I shoot very light loads so this alteration allows the bolt to cycle from the light blowback action of my loads. Now I am looking to add more weight to the buffer to add a little time duration before the bolt starts to blowback, which is doable. I got this idea from radiusing my ruger 10/22 rifle bolt. Same principle. The 10/22 radiused bolt cycles all types of ammunition without a hitch, especially the subsonic brands. I mainly shoot hand loaded subsonic 147gr lead through the carbine, but have also shot +P, and +P+ 124gr jacketed ammunition through the carbine too, and all of it feeds and ejects well. Well enough for me to use a brass catcher bag on the carbine without any feeding or ejection failures. The shells are a little sooty which is why I think the increased weight in the buffer will help. Your mileage may vary, but the short ramp and the radius works very well for me. After the initial 500 rounds to get it working 100%, I have about 2700 rounds through the carbine. Good luck with the project. eieio |

|

|

|

|

Please post a picture of your ramped/radiused 10/22 bolt. Would like to have my 10/22 run subsonic reliably. Thanks in advance. Gary

|

|

|

|

|

Could you informed fellows confirm something for me ??

I'm close to getting my form 4 complete on a semi-auto integrally suppressed SBR'd 9mm I was planning on having the bolt ramped BUT if I'm reading all this info. correctly a ramped bolt on a semi-auto 9mm with a 9mm hammer is unnecessary , have I got that right ???????? THANKS

|

|

|

" the accumulation of all powers, legislative, executive, and judiciary, in the same hands, whether of one, a few, or many, and whether hereditary, self-appointed, or elective, may justly be pronounced the very definition of tyranny " J. Madison<

|

a ramped bolt, with a semi-auto 9mm hammer will not work. |

||

|

I'm no good at telling people what they want to hear when I dont believe it myself :)

|

OK. so ramping a bolt on a 9mm AR is really only necessary to mitigate potential problems when using a 5.56 hammer ? a 9mm hammer makes the whole bolt ramping issue moot ?? Thanks again (my OCD is getting the best of me  ) )

|

|||

|

" the accumulation of all powers, legislative, executive, and judiciary, in the same hands, whether of one, a few, or many, and whether hereditary, self-appointed, or elective, may justly be pronounced the very definition of tyranny " J. Madison<

|

NO, ramping a bolt is to make cocking of the hammer(any hammer) easier/smoother. |

||

|

I'm no good at telling people what they want to hear when I dont believe it myself :)

|

What is the intended purpose of said notch anyway? BTW - I asked in another thread about using the JP speed hammer with a RRA 9mm bolt. Sure enough that JP hammer will hang up in the notch (but the RRA 9mm hammer will function OK) |

||

|

GunCat ~ Kentucky

Rose Action Sports *Quality Gunsmithing for the 18th to 21st Century* www.roseactionsports.com |

So ADCO, does the 9mm hammer make ramping a moot issue? I just installed a DPMS hammer in my cav lower. Should I get my bolt ramped? |

||||

|

The sheep generally do not like the sheepdog. He looks a lot like the wolf. He has fangs and the capacity for violence. The difference, though, is that the sheepdog must not, can not and will not ever harm the sheep.- Grossman

Lord, make me a sheepdog |

|

I just installed a DPMS hammer in my cav lower. Should I get my bolt ramped?

While the DMPS hammer will work fine, things will be much smoother and easier on your gun if you get the bolt ramped. |

|

|

I'm no good at telling people what they want to hear when I dont believe it myself :)

|

to make it harder to convert the gun to full auto. If the hammer misses the disconnector and follows the bolt home - the hammer gets caught in the that notch. the bolt notch is menat to catch the notch in the back of regualr semi auto hammers. This is why DPMS hammers work, the are rounded - not notched so they dont get caught. |

||

|

I'm no good at telling people what they want to hear when I dont believe it myself :)

|

You're just trying to get business aren't you Well, when I actually am able to pull the money together for my upper, I'll send you my bolt. How much do you charge? |

||

|

The sheep generally do not like the sheepdog. He looks a lot like the wolf. He has fangs and the capacity for violence. The difference, though, is that the sheepdog must not, can not and will not ever harm the sheep.- Grossman

Lord, make me a sheepdog |

|

Very informative thread.

I'm in Canada so I can't send my bolt to be ramped by Adco. My gunsmith can mill it for me. If its not a trade secret what is the optimal depth of the cut, length and angle. I hope I'm not stepping in any toes here. |

|

|

|

|

I just finished rebuilding my suppressed 9mm SBR. Converted into a side charger using a ASA 9mm side charging upper. had to not the bolt to work with the side charger. figured since I was doing some machining anyways. I might as well ramp the bolt. I did not go as short as the ADCO ramp, I went about 1 1/4 in length. after I put it all back togethere.......wow, what a difference. I was amazed at the felt difference of manually charging the bolt. a lot easier and smoother...........looks like I'll have to do the other one and the 7.62x25 also............

|

|

|

www.molonlabe.com

|

It's not a trade secret on my end. I will put pics together showing everything I did and the rationale behind it. Unless there are objections. |

||

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.