|

Posted: 8/28/2014 4:06:01 PM EDT

ETA: This thread reads fine in Firefox and IE, for some reason Chrome makes the videos show up in a stagger.

I’ve had request to start a thread in the AR Discussion forum to specifically discuss the bumpsaw/Homemade IAR concept and my build in particular. I thought it would be a good idea to explain a few of the issues that semi auto bumps guns experience and ways to avoid those pitfalls. This thread should also be a good place to share your bump gun experiences and answer questions for individuals who would like to build their own. First off some video: 40rd PMAG  40rd Pmag dump. Two 30rd mags.  Bipod bump. 60rd Surefire  60rd Surefire dump from bump stock Now to the theory. Timing: Timing is very important in machineguns, keeping everything operating in order and in the right sequence. The M16 utilizes the autosear to keep the rifle in time and operating correctly. Unfortunately a legal autosear is very expensive. Bumpguns unfortunately don’t have internal timing control, so if you cycle the trigger too fast you will experience a hammer follow with a live round in the chamber and a dead trigger. When assembling your bumpgun this needs to be considered if you don’t want to be clearing malfunctions every 15, 30 or 100rds. For a typical 700rpm cyclic rate the complete firing cycle happens in 85 milliseconds. Increasing the cycle rate to 900rpm brings that down to 67 milliseconds. Jerry Miculek runs splits around 100miliseconds, so what may not cause an issue with a stock M4, can quickly lead to an issue on a bumpgun that may exceed 900rpm. Worse, if the majority of your burst is happening at 85 milliseconds, but one gets tripped early at 45 milliseconds, you’re sitting on a dead gun. How to control it – The biggest issue is getting the bolt closed before the hammer strikes, so a faster cycle time is very desirable. To decrease the time needed you can reduce mass, increase gas or increase spring tension. You can reduce mass in the bolt, buffer or both. Reducing buffer weight increases the likelihood of bolt bounce so you don’t want to remove the buffer weights. I utilized an AR15 carrier with a standard carbine buffer. I think a lightweight carrier with an H or H2 buffer would be a better option, but quickly increases cost. Increased spring rate speeds up the carrier closing; I utilized a Tubbs flatwire spring as they claimed it helps reduce bolt bounce(Update: I now use a Sprinco Orange spring as it is significantly stronger than the Tubbs.). The next big contributor to timing is the lock time of the hammer. According Geissele’s Hi-Speed flyer their trigger has a 4millisecond lock time compared to a stock 10 millisecond lock time. (http://d3cfki0l5o2ps6.cloudfront.net/media/files/hi-speed-natl-match-rifle-trigger-pf.pdf) An SD3G is probably running between a 4ms and 8ms lock time as the hammer profile is slightly heavier than the Hi-Speed. The faster your hammer is, the less time you have to get the carrier closed. Utilizing a slower hammer design is beneficial to reliability for a bumpgun. I also used a .010 longer firing pin, so the carrier could be 10 thousands out of battery and I could still get a solid primer ignition. Trigger selection: When looking for a trigger you want a short reset, very little over travel and a standard lock time. My experience with the SD3G is that it’s too good for a bump gun. The reset is extremely short (.06”) and lock time is fairly quick. I went with a JARD 4.5lb adjustable trigger. Reset is still pretty short, trigger weight is not too light and the lock time is similar to a mil spec trigger (maybe a little slower). Quite a few triggers will work, but too much weight can make it hard to use in some positions. A longer reset will require more front to back movement in the stock and may be harder to trip reliably. Running the gun: Bumpguns are fairly easy to use, I utilize mine like a SAW or 240. The support hand goes over the stock providing both stability and forward pressure to keep the gun running. At first I was trying to push forward with my support hand. I’ve found it works better to place the support hand on the stock with pressure against the charging handle. Then grip the stock tightly, the rifles recoil will compress the meat of your hand and then your hand will uncompress pushing the rifle back forward slightly and tripping the trigger. Total movement needed is under ¼”. Once the support hand is firmly in position lean into the bipod and pull the trigger. Your finger will stop on the trigger rest and the rifle will cycle until you remove the finger. Stock Choices: Right now there are three choices for factory bump stocks. First is the SlideFire, kind of high at $300, but has worked for a lot of people. Next is the Fostech, Really nice design, but even more expensive at $500. This stock will run faster than the slidefire because it is a smoother design. SkilletsUSMC has used grease inside of his to slow it down and help with hammer follow issues. The third and most recent introduction is the $100 Bump Fire Systems stock. http://www.bumpfiresystems.com/ UPDATE: The Bump Fire Systems Stock does not allow full retraction of the charging handle when the stock is locked in place. My favorite option is the build it yourself stock. I’ll post later with details on my Magpul Fixed MOE stock and MIAD grip bump stock conversion. Bipods: Effective use of the bumpsaw is done with a good bipod. The bipod provides a solid shooting position and lets you use the bumpgun like a real machinegun. Some guys (SkilletsUSMC) are using the M60 bipod modified to allow some front to back movement and attach to the AR. I prefer the GG&G bipod – largely because I think it looks good. In my experience, if you use a short reset trigger you won’t need any forward bipod movement. If you want accurate distant fire you will spend most of your time using the bipod. Remember that whatever bipod you choose, your going to want enough height to clear a Surefire 60 and PMAG 40. General Part Choices: Your going to put a lot of rounds through this rifle. A chrome lined chamber is IMO a must. I wouldn’t waste money on a high end barrel; you’re probably going to burn it out with a few mag dumps. A heavy barrel will take longer to heat up and is less likely to cook off after a few mags. Gas port location can make a difference. A carbine gas system is more likely to have stuck case issues and will be more quickly affected by gas port erosion. A rifle length gas system will work well on an 18” or 20” gun but may not like Tulammo on a 16” barrel. A midlength is probably ideal as you are likely to have fewer issues with over-gassing and extraction. Port erosion will happen faster than the rifle length, but slower than the carbine gas system. A BAD lever really comes in handy when changing mags from the prone. It also makes it easy to lock the bolt open and help it cool off between strings. An extractor O-ring will help with extraction when your rifle gets dirty after 10-20 mags without cleaning. Might as well start with one. A sprinco extractor spring IIRC is rated for a million cycles, it’s probably a good choice as well. Either way I would plan ahead with a spare extractor, spring and O-ring for when you start wearing parts out. Weight: Too much weight will slow down your rifle, some stocks are more sensitive than others to weight. (The Fostech is less sensitive than the others.) Remember you will probably want to use some beta mags and surefire 60 rd mags, and they add a lot of weight on their own. Reduced weight will increase your cyclic rate. IME a little extra weight isn’t a problem as long as you have a nice trigger. If you’re trying to use a stock AR trigger you will need to keep your weight down. Theoretical Improvements: I’ve thought about several ways to improve my bumpsaw. For a faster cycle time you could use a boomfab titanium carrier and combine it with a H or H2 buffer. This would ensure no bolt bounce issues occurred while allowing the use of a faster reset trigger (Maybe even the SD3G). I think this combination might allow very rapid rates of fire (1100 rpm anyone?) without experience hammer follow. If you shoot a lot of rounds heat will quickly become an issue. Burst gas tubes are likely if you start doing beta dumps. I’m utilizing a melonited gas tube to increase gas tube life. V7 makes an inconel gas tube that looks like it would really take a beating, but the $70 price is kind of high. Alternatively a piston might alleviate the gas issue. Pistons vary wildly in design and may introduce their own problems. Even if you mitigate the burst gas tube problem, you may soon run into a burst barrel problem. JP sells heatsinks that would likely help keep your rifle running longer. Some rails are designed with heat sinks that will help remove heat from the chamber. This type of build is a good candidate for an enhanced bolt. The AR15Performance Superbolt, LWRC Advanced Combat Bolt or Sharps S7 Relia-Bolt (Sharps bolts have had failure issues and I wouldn't try one in my bump gun.)should all last through multiple barrels. My build specs: Delton 16” Dissipator (rifle gas) barrel with .110 gas port (I’m going to open it to .125 pretty soon). Spikes melonited rifle length gas tube. Rainier flash hider. Bushmaster AR-15 carrier (it’s what I had laying around). Rguns NIB bolt (the carrier was swapped to reduce weight). Viton O-ring. RedX 7.62x39 firing pin. A4 upper receiver. KAC M5 rail. Delton lower receiver. Blackhawk lower parts kit. JARD 4.5lb adjustable trigger. PSA 7075 T6 buffer tube. Tubb Flatwire Spring. Sprinco Orange spriing. Standard Carbine Buffer. MIAD Grip (modified). MOE Fixed Carbine Stock (modified). BAD lever. I want to say thanks to SkilletsUSMC for inspiring me to put this together. Madhat72 and Backbencher have also contributed heavily to the Slide Fire haters thread and helped me generate my thoughts on this setup. http://www.ar15.com/forums/t_1_5/1641834_Slide_Fire_haters_never_really_showed_up__Fire_and_movement_successful__Updated__8_25_2014__.html&page=1 |

|

|

|

I used the Fixed MOE stock because I wanted to cover up the support rod that connects the grip to the rifle.

http://www.aimsurplus.com/product.aspx?groupid=990&name=Magpul+MOE+Fixed+Carbine+Stock+%E2%80%93+Mil-Spec. The MIAD grip was used so that the metal insert could be slid inside. http://www.aimsurplus.com/product.aspx?groupid=1699&name=Magpul+MIAD+Gen+1.1+Mission+Adaptable+Grip First I took the clip out of the MOE stock. The internal clip locks up pretty tight to the receiver extension, and I needed the stock to float back and forth. Then I cut the inside of the stock so a 7" long 1/2" by 1/8" steel rod could be inserted. I tapped the rod so two screws would hold it in place. I then bent the rod so it would curve along the bottom side of the receiver and down into the grip. I cut the backstrap of the MIAD grip so the rod could exit the grip. I then put two 1/8" roll pins through the receiver so I would have a rail for the grip to ride on. The MIAD grip was then cut with a file so that it had an internal rail that slid over the two 1/8" roll pins. This keeps the grip from pulling away from the reciever while allowing the needed front to back play. (ETA: I later added a roll pin between the grip and the metal rod, so they're permanently affixed together now.) The forward and back travel of the stock is limited by a roll pin passed through the receiver extension and two small slots milled into the side of the stock. I needed a finger stop, so I screwed the extra front strap from the MIAD grip to the side of the MIAD grip. (ETA: I later added a secondary roll pin so the finger stop cant rotate out of position.) The safety whole was tapped, and threaded 8x32 and I put a set screw in it to hold the safety spring and detent in. I cut the safety detent in half so it would have enough room to travel up and down put a smaller spring in. To disassemble the stock system you take out the rear roll pin, slide the stock back about an 1/8" past where it can normally go and then slide the grip straight down off of the rod. (ETA: I've since pinned the grip to the connecting rod, so I now have to unscrew the stock from the connecting rod to disassemble.) It took a few hours to fit everything the way I wanted. In the end I am happy with the way it looks and very pleased with it's performance. Took less than $100 in parts, I've already burned far more than that in ammunition. |

|

|

|

A quick note: the M60 bipod was chosen by me for not only looks, but for it's ability to extend to VERY tall. Some mags don't clear well (40rnd PMAGs, SF60s). I like being able to adjust out a ways.

For people interested in how I got my M60 bipod to mount, I have a DIY thread here. |

|

|

|

Tag for more - thanks jaqufrost.

I was originally one of the guys who were skeptical about the practical utility of bump fire stocks, even from a theoretical standpoint. I did not think that they could be made to function reliably and consistently enough from a prone position and accurately deliver rounds on target to be viable for anything other than recreational burning off of rounds, which is not to say that purely recreational use is not a legitimate use - once again, I'm merely approaching this from a theoretical standpoint of "if" you wanted to replicate a Squad Automatic or Light Support Weapon or Automatic Rifle capability in a non-NFA package. I'm happy to at least begin nibbling on crow after having seen some of jaqufrost and SkilletsUSMC's recent videos on the subject and interested to see what others think/can come up with. ~Augee |

|

|

|

I see a winter project in the making.

Like I said in that other thread, I have a 16" midlength upper with nothing to do... Tagged. |

|

|

|

augee, Go back to the last few pages of the slide fire haters thread. I deliberately shoot idpa full sized steel while suppressed, so you can hear the hits. I also post accuracy pics. It's accurate, controllable and works!

|

|

|

|

|

|

Quoted: Did you use the JARD single or two stage adjustable trigger? View Quote http://www.brownells.com/rifle-parts/triggers-parts/triggers/ar-15-ar-custom-trigger-kit-prod1466.aspx ETA: MFR part 1025 |

|

|

|

I want to start a build like this, should I start with a heavy profile/ midlength barrel?

|

|

|

|

|

|

Quoted: I want to start a build like this, should I start with a heavy profile/ midlength barrel? View Quote I would definitely get a chrome lined or melonited barrel. |

|

|

|

Quoted:

I think the heavy profile midlength is an excellent option. The heavy profile helps keep the chamber from overheating too quickly and the midlength is a very versatile gas location. You are unlikely to experience issues with Tulammo or overpressure extraction issues from M193/M855. I would definitely get a chrome lined or melonited barrel. View Quote View All Quotes View All Quotes Quoted:

Quoted:

I want to start a build like this, should I start with a heavy profile/ midlength barrel? I would definitely get a chrome lined or melonited barrel. I almost picked up an 18" HBAR 1:7 melonited bbl yesterday. I didn't bite because I don't have a better mount for my bipod. I need to get jm0502 to macht schnell on that M60 bipod adapter.... |

|

|

|

I had thought about building one my self, so I really liked seeing the home made one, I like how you did it. You could run another piece of steel to the bottum of the grip for rigididy, like a thumb hole design. Does anybody make a Thumb hole stock for AR15s? That's be the best place to start.

Do any of these stocks have a spring in the stock? As soon as I saw the slide fire I assumed it had a spring, but after research it appears that you have to push forward with your off hand? Would ATF sign off on having a spring in the stock to cause the firearm to reciprocate? Big question here: What do you do with the selector detent spring?? How about making one based on a sig brace design? That'd be cool. |

|

|

|

I know Jaqufrost covered it, but I would like to say this again:

DO NOT ADD A SPRING TO YOUR BUMP STOCK OR YOU ARE MAKING AN ILLEGAL MACHINE GUN.

|

|

|

|

Quoted:

There are some thumb hole fixed stocks, but I don't think they are in production any more. They utilize the rifle receiver extension which is completely round and does not offer any side-side resistance. spring and they wYou cannot add a spring. The original Atkisson design added a ere collected by ATF as machineguns.I threaded the detent hole 8-32 and put a short set screw in it. Then I cut the detent in half and used a small spring from a box of random springs I bought at Ace Hardware a few years ago. http://i739.photobucket.com/albums/xx39/jaqufrost/Mobile%20Uploads/2014-07/20140719_201526_zpscufizlct.jpg View Quote View All Quotes View All Quotes Quoted:

Quoted:

I had thought about building one my self, so I really liked seeing the home made one, I like how you did it. You could run another piece of steel to the bottum of the grip for rigididy, like a thumb hole design. Does anybody make a Thumb hole stock for AR15s? That's be the best place to start. Do any of these stocks have a spring in the stock? As soon as I saw the slide fire I assumed it had a spring, but after research it appears that you have to push forward with your off hand? Would ATF sign off on having a spring in the stock to cause the firearm to reciprocate? Big question here: What do you do with the selector detent spring?? How about making one based on a sig brace design? That'd be cool. spring and they wYou cannot add a spring. The original Atkisson design added a ere collected by ATF as machineguns.I threaded the detent hole 8-32 and put a short set screw in it. Then I cut the detent in half and used a small spring from a box of random springs I bought at Ace Hardware a few years ago. http://i739.photobucket.com/albums/xx39/jaqufrost/Mobile%20Uploads/2014-07/20140719_201526_zpscufizlct.jpg Oh yeah, you jogged my memmory, I seem to recall that. |

|

|

|

|

|

|

|

Question:

What if I want a slower RoF? Like 600-750? Is that doable? How would you suggest going about that? |

|

|

|

Quoted: Question: What if I want a slower RoF? Like 600-750? Is that doable? How would you suggest going about that? View Quote A heavier buffer (provides slightly more pause at rear of the stroke), more rifle weight, a slightly longer trigger reset, and less gas are all good methods of reducing the rate of fire. An adjustable gas block like the multi position governor block would be great, then you could start with a small gas gort ajd enlarge it as wanted for increased rate of fire and reliability with a greater variety of ammunition. I believe my current setup is running about 750 most the time.

|

|

|

|

Quoted:

I would grease the reciever extension. SkilletsUSMC used grease on his fostech to slow it down slightly. A heavier buffer (provides slightly more pause at rear of the stroke), more rifle weight, a slightly longer trigger reset, and less gas are all good methods of reducing the rate of fire. An adjustable gas block like the multi position governor block would be great, then you could start with a small gas gort ajd enlarge it as wanted for increased rate of fire and reliability with a greater variety of ammunition. I believe my current setup is running about 750 most the time. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Question: What if I want a slower RoF? Like 600-750? Is that doable? How would you suggest going about that? A heavier buffer (provides slightly more pause at rear of the stroke), more rifle weight, a slightly longer trigger reset, and less gas are all good methods of reducing the rate of fire. An adjustable gas block like the multi position governor block would be great, then you could start with a small gas gort ajd enlarge it as wanted for increased rate of fire and reliability with a greater variety of ammunition. I believe my current setup is running about 750 most the time. Cool, I'm intending on building something like this later this year and my goal is a reliable but low RoF so I can get easily regulated 5-6 shot bursts. Make it less of a toy for making noise and into a real IAR-type weapon. |

|

|

|

Quoted:

Cool, I'm intending on building something like this later this year and my goal is a reliable but low RoF so I can get easily regulated 5-6 shot bursts. Make it less of a toy for making noise and into a real IAR-type weapon. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Quoted:

Question: What if I want a slower RoF? Like 600-750? Is that doable? How would you suggest going about that? A heavier buffer (provides slightly more pause at rear of the stroke), more rifle weight, a slightly longer trigger reset, and less gas are all good methods of reducing the rate of fire. An adjustable gas block like the multi position governor block would be great, then you could start with a small gas gort ajd enlarge it as wanted for increased rate of fire and reliability with a greater variety of ammunition. I believe my current setup is running about 750 most the time. Cool, I'm intending on building something like this later this year and my goal is a reliable but low RoF so I can get easily regulated 5-6 shot bursts. Make it less of a toy for making noise and into a real IAR-type weapon. I think that's what we are all going for here. |

|

|

|

I'm working on something like this, only with a Geissele S3G and no bump stock. Thanks for making the thread.

|

|

|

|

Quoted: I'm working on something like this, only with a Geissele S3G and no bump stock. Thanks for making the thread. View Quote |

|

|

|

Quoted:

If you find a way around the hammer follow issue let me know. IME with the SD3G it tripped to fast and outran the carrier. I know SkilletsUSMC also had some issues with his. I haven't been able to try it with a titanium carrier though. I know RedX has a titanium carrier for $300. I think boomfab's is closer to $500 but saves another ounce or two. View Quote View All Quotes View All Quotes Quoted:

Quoted:

I'm working on something like this, only with a Geissele S3G and no bump stock. Thanks for making the thread. This guy seems to handle it without a problem: http://youtu.be/Vvr0rSaFgZE |

|

|

|

View Quote View All Quotes View All Quotes Quoted: Quoted: Quoted: I'm working on something like this, only with a Geissele S3G and no bump stock. Thanks for making the thread. This guy seems to handle it without a problem: http://youtu.be/Vvr0rSaFgZE |

|

|

|

View Quote View All Quotes View All Quotes Quoted:

Quoted:

Quoted:

I'm working on something like this, only with a Geissele S3G and no bump stock. Thanks for making the thread. This guy seems to handle it without a problem: http://youtu.be/Vvr0rSaFgZE Not really the same thing. He's at 500rpm MAYBE for a second and within 50' of his target. He's a good shooter, but I doubt he could keep that going for long. We're talking about shooting at longer distances, keeping a rate of fire around 700,and being able to do it until the barrel bursts. |

|

|

|

Quoted:

I then put two 1/8" roll pins through the receiver so I would have a rail for the grip to ride on. http://i739.photobucket.com/albums/xx39/jaqufrost/Mobile%20Uploads/2014-07/20140719_201438_zpsbxivocbi.jpg The MIAD grip was then cut with a file so that it had an internal rail that slid over the two 1/8" roll pins. This keeps the grip from pulling away from the reciever while allowing the needed front to back play. http://i739.photobucket.com/albums/xx39/jaqufrost/Mobile%20Uploads/2014-07/20140719_201211_zpsxb0rwxfs.jpg The forward and back travel of the stock is limited by a roll pin passed through the receiver extension and two small slots milled into the side of the stock. http://i739.photobucket.com/albums/xx39/jaqufrost/Mobile%20Uploads/2014-07/20140720_162337_zpsuoyertcg.jpg http://i739.photobucket.com/albums/xx39/jaqufrost/Mobile%20Uploads/2014-07/20140720_162356_zpstxxfd4pm.jpg View Quote Could you skip the roll pins in the receiver by simply allowing the receiver's grip area to align the grip? Drill two holes in your steel flat material coming out of the stock so that it can be screwed to the grip. Now the only roll pin needed should be the extension roll pin. If some support/alignment is needed on the grip side, I'd simply slot the grip screw hole and let it do the alignment if there's enough room for travel. Thoughts? Wes |

|

|

|

Quoted: Could you skip the roll pins in the receiver by simply allowing the receiver's grip area to align the grip? Drill two holes in your steel flat material coming out of the stock so that it can be screwed to the grip. Now the only roll pin needed should be the extension roll pin. If some support/alignment is needed on the grip side, I'd simply slot the grip screw hole and let it do the alignment if there's enough room for travel. Thoughts? Wes View Quote View All Quotes View All Quotes Quoted: Quoted: I then put two 1/8" roll pins through the receiver so I would have a rail for the grip to ride on. http://i739.photobucket.com/albums/xx39/jaqufrost/Mobile%20Uploads/2014-07/20140719_201438_zpsbxivocbi.jpg The MIAD grip was then cut with a file so that it had an internal rail that slid over the two 1/8" roll pins. This keeps the grip from pulling away from the reciever while allowing the needed front to back play. http://i739.photobucket.com/albums/xx39/jaqufrost/Mobile%20Uploads/2014-07/20140719_201211_zpsxb0rwxfs.jpg The forward and back travel of the stock is limited by a roll pin passed through the receiver extension and two small slots milled into the side of the stock. http://i739.photobucket.com/albums/xx39/jaqufrost/Mobile%20Uploads/2014-07/20140720_162337_zpsuoyertcg.jpg http://i739.photobucket.com/albums/xx39/jaqufrost/Mobile%20Uploads/2014-07/20140720_162356_zpstxxfd4pm.jpg Could you skip the roll pins in the receiver by simply allowing the receiver's grip area to align the grip? Drill two holes in your steel flat material coming out of the stock so that it can be screwed to the grip. Now the only roll pin needed should be the extension roll pin. If some support/alignment is needed on the grip side, I'd simply slot the grip screw hole and let it do the alignment if there's enough room for travel. Thoughts? Wes |

|

|

|

Quoted:

Yes, I believe that would work fine. I put the roll pins in to provide extra support in the event the grip is pulled away from the receiver. The grip screw will need left unscrewed quite a ways because of the angle it attaches to the receiver. I just went ahead and put the roll pins in because receivers are cheap and it was a fairly simple solution. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Quoted:

I then put two 1/8" roll pins through the receiver so I would have a rail for the grip to ride on. http://i739.photobucket.com/albums/xx39/jaqufrost/Mobile%20Uploads/2014-07/20140719_201438_zpsbxivocbi.jpg The MIAD grip was then cut with a file so that it had an internal rail that slid over the two 1/8" roll pins. This keeps the grip from pulling away from the reciever while allowing the needed front to back play. http://i739.photobucket.com/albums/xx39/jaqufrost/Mobile%20Uploads/2014-07/20140719_201211_zpsxb0rwxfs.jpg The forward and back travel of the stock is limited by a roll pin passed through the receiver extension and two small slots milled into the side of the stock. http://i739.photobucket.com/albums/xx39/jaqufrost/Mobile%20Uploads/2014-07/20140720_162337_zpsuoyertcg.jpg http://i739.photobucket.com/albums/xx39/jaqufrost/Mobile%20Uploads/2014-07/20140720_162356_zpstxxfd4pm.jpg Could you skip the roll pins in the receiver by simply allowing the receiver's grip area to align the grip? Drill two holes in your steel flat material coming out of the stock so that it can be screwed to the grip. Now the only roll pin needed should be the extension roll pin. If some support/alignment is needed on the grip side, I'd simply slot the grip screw hole and let it do the alignment if there's enough room for travel. Thoughts? Wes Threaded rod would probably work better than leaving the screw really far out. Wes |

|

|

|

Jaqufrost: You've spent some time really analyzing the SD3G, but I was pondering a simple solution to the issues of HF that come with using it on a bump-SAW. Ouside of how awesome the trigger is itself, one of the big things that is different about the SD3G than most other triggers is the flat bow. The trigger is activated earlier than a normally curved trigger just due to it's shape.

I wonder if the issues of HF would lessen or disappear if the finger rest tabs of a bump stock were extended out the same distance that the SD3G adds to a milsepc trigger. I am inclined to try it. |

|

|

|

Quoted:He doesn't appear to be bumping the gun, just pulling the trigger quickly View Quote View All Quotes View All Quotes Quoted:

Not really the same thing. He's at 500rpm MAYBE for a second and within 50' of his target. He's a good shooter, but I doubt he could keep that going for long. We're talking about shooting at longer distances, keeping a rate of fire around 700,and being able to do it until the barrel bursts. I did say I wasn't making it a bump fire gun. I thought this was the IAR build thread. I figure 5-10 shot strings on target with that trigger would provide pretty damn good "IAR" performance out of a semi-auto AR built in an IAR configuration otherwise. |

|

|

|

Quoted: I did say I wasn't making it a bump fire gun. I thought this was the IAR build thread. I figure 5-10 shot strings on target with that trigger would provide pretty damn good "IAR" performance out of a semi-auto AR built in an IAR configuration otherwise. View Quote View All Quotes View All Quotes Quoted: Quoted:He doesn't appear to be bumping the gun, just pulling the trigger quickly Quoted: Not really the same thing. He's at 500rpm MAYBE for a second and within 50' of his target. He's a good shooter, but I doubt he could keep that going for long. We're talking about shooting at longer distances, keeping a rate of fire around 700,and being able to do it until the barrel bursts. I did say I wasn't making it a bump fire gun. I thought this was the IAR build thread. I figure 5-10 shot strings on target with that trigger would provide pretty damn good "IAR" performance out of a semi-auto AR built in an IAR configuration otherwise. |

|

|

|

View Quote View All Quotes View All Quotes Quoted: Quoted: Quoted: I'm working on something like this, only with a Geissele S3G and no bump stock. Thanks for making the thread. This guy seems to handle it without a problem: http://youtu.be/Vvr0rSaFgZE |

|

|

|

If anyone is looking for a good deal on a burner barrel, this 18" model looks pretty good for $120.

|

|

|

|

Quoted: I had thought about building one my self, so I really liked seeing the home made one, I like how you did it. You could run another piece of steel to the bottum of the grip for rigididy, like a thumb hole design. Does anybody make a Thumb hole stock for AR15s? That's be the best place to start.

Do any of these stocks have a spring in the stock? As soon as I saw the slide fire I assumed it had a spring, but after research it appears that you have to push forward with your off hand? Would ATF sign off on having a spring in the stock to cause the firearm to reciprocate? Big question here: What do you do with the selector detent spring?? How about making one based on a sig brace design? That'd be cool. View Quote Thumb hole stocks are available from New Zealand & Europe. I did a reasonably extensive search a little over a year ago & cataloged the results here: http://www.feinsteinproject.org/loes/effortwoodstock/effortWoodstock.html I'm currently working on a thumbhole stock that would use a standard mil-spec carbine buffer tube (receiver extension), but I'm a bit creatively stuck @ the moment. You can see where I'm @ in the GD bumpfire thread here: http://www.ar15.com/forums/t_1_5/1641834_Official_Bump_SAW_GD_thread__BFS_stock_cut_for_function_p_25.html&page=21#i48903482 |

|

|

|

I wonder whether some of the issues with ROF, etc. could be addressed using some of the items that have been developed for use with LMG/LSW/IAR variants.

Some thoughts: - I'm not an engineer - would stronger recoil springs help or hurt, and/or would some sort of "nestled" spring design similar to that which is used on the [impractically fast] M231 have a positive or negative effect? - Multi-position (not just suppressed/unsuppressed) adjustable gas blocks - Hydraulic buffers - I know that poorly designed versions have leaked and otherwise caused troubles in even semi-automatic use, but they were originally developed for full automatic LMG/LSW variants - PRI "Fatboy" gas tube in addition to some of the other designs (i.e. melonited, inconel, etc.) In addition, some ergonomic/configuration thoughts on what might "make the most" of this kind of set up - First of all - I suddenly have the desire to see someone use the TAPCO SAW grip on an AR.

Beyond that - - IMHO, it would seem to me that a FF forearm design would be almost required to get sufficient air circulation compared to "wrapped" heat shield designs that will simply reflect barrel heat back on to the barrel, rather than helping it to dissapate, contributing to cook off issues with a closed bolt system - incidentally, I wonder how well any of those funky "heat sink" designs or even a "finned" barrel might be worthwhile in this kind of setup. - Basing things just on, say, the PARA SAW variants - I know that there's a lot of talk of 16" barrels for ease and convenience - and plus, a big part of the reason for this is to "avoid NFA," but for the most part - the issue has been avoiding the $12K+ investment in an RR - SBRs are still relatively accessible to most people - is a 16" barrel really necessary from a weight/utility standpoint compared to say a 12.5"? In terms of the employment of suppressive/fixing fires, with a fusillade of rounds heading downrange - could we more or less accomplish the same downrange effects with a shorter, more maneuverable barrel length? Maybe in a "Kino" configuration to increase iron sight radius, a well. - For those of you that have these/have used them - how is the controllability at max ROF? I know that we've established that they're relatively easy to keep on target and aim, etc. but some weapons are simply easier to control on automatic than others - typically it's an issue of the heavier, the smoother firing (with the commensurate penalty to the poor guy who has to carry it) but are users finding themselves having to "fight" the gun at max ROF? Would it benefit from the use of, say, a BattleComp or similar "flash comp," more so than a semi-automatic weapon would in practical use? - The MATECH adjustable BUIS seems almost purpose designed for this application for iron sights - optics wise - for those of you using optics - particularly magnified optics - how is that working out for you? Granted, I'm a big proponent of RDS, and particularly EOTechs on support-type weapons for many applications - but there is, undoubtedly an application where magnified optics would be desireable and preferable with this kind of capability - with the weapon moving back and forth to accomplish the "bump," do you think you could still be able to use a magnified optic of any kind? ~Augee |

|

|

|

|

|

Quoted: I wonder whether some of the issues with ROF, etc. could be addressed using some of the items that have been developed for use with LMG/LSW/IAR variants. Some thoughts: - I'm not an engineer - would stronger recoil springs help or hurt, and/or would some sort of "nestled" spring design similar to that which is used on the [impractically fast] M231 have a positive or negative effect? Do you have any more information on the M231 spring setup? - Multi-position (not just suppressed/unsuppressed) adjustable gas blocks I've been thinking a governah block would be nice. http://micromoa.com/ - Hydraulic buffers - I know that poorly designed versions have leaked and otherwise caused troubles in even semi-automatic use, but they were originally developed for full automatic LMG/LSW variants Are their any other players besides Enedine? I think they make the buffer for the M240. - PRI "Fatboy" gas tube in addition to some of the other designs (i.e. melonited, inconel, etc.) I think a better fix/adjustment would be an adjustable gas block. In addition, some ergonomic/configuration thoughts on what might "make the most" of this kind of set up - First of all - I suddenly have the desire to see someone use the TAPCO SAW grip on an AR.  Beyond that - - IMHO, it would seem to me that a FF forearm design would be almost required to get sufficient air circulation compared to "wrapped" heat shield designs that will simply reflect barrel heat back on to the barrel, rather than helping it to dissapate, contributing to cook off issues with a closed bolt system - incidentally, I wonder how well any of those funky "heat sink" designs or even a "finned" barrel might be worthwhile in this kind of setup. I would avoid any closed rails/tubes. A heatsinked rail makes sense as it should remove heat from the chamber. I would love to see some thermal readings from the barrel with and without a heatsink used. - Basing things just on, say, the PARA SAW variants - I know that there's a lot of talk of 16" barrels for ease and convenience - and plus, a big part of the reason for this is to "avoid NFA," but for the most part - the issue has been avoiding the $12K+ investment in an RR - SBRs are still relatively accessible to most people - is a 16" barrel really necessary from a weight/utility standpoint compared to say a 12.5"? In terms of the employment of suppressive/fixing fires, with a fusillade of rounds heading downrange - could we more or less accomplish the same downrange effects with a shorter, more maneuverable barrel length? Maybe in a "Kino" configuration to increase iron sight radius, a well. I think the concept would work. But your grazing fire capability will be more limited with the velocity loss. - For those of you that have these/have used them - how is the controllability at max ROF? I know that we've established that they're relatively easy to keep on target and aim, etc. but some weapons are simply easier to control on automatic than others - typically it's an issue of the heavier, the smoother firing (with the commensurate penalty to the poor guy who has to carry it) but are users finding themselves having to "fight" the gun at max ROF? Would it benefit from the use of, say, a BattleComp or similar "flash comp," more so than a semi-automatic weapon would in practical use? Mine is already very controllable. I preload the bipod like shooting a precision rifle or regular machinegun. I'll have to try it with a Comp sometime. Mine is already kinda heavy so if the comp is too effective it might make it more difficult to bump. - The MATECH adjustable BUIS seems almost purpose designed for this application for iron sights - optics wise - for those of you using optics - particularly magnified optics - how is that working out for you? Granted, I'm a big proponent of RDS, and particularly EOTechs on support-type weapons for many applications - but there is, undoubtedly an application where magnified optics would be desireable and preferable with this kind of capability - with the weapon moving back and forth to accomplish the "bump," do you think you could still be able to use a magnified optic of any kind? I'm using a MATECH. I use them quite a bit though as they are priced right and work well. I think a low power magnified optic would work fine. Our SAW's are issued with ACOG's now and I think a similar ACOG would be a good choice. ~Augee View Quote |

|

|

|

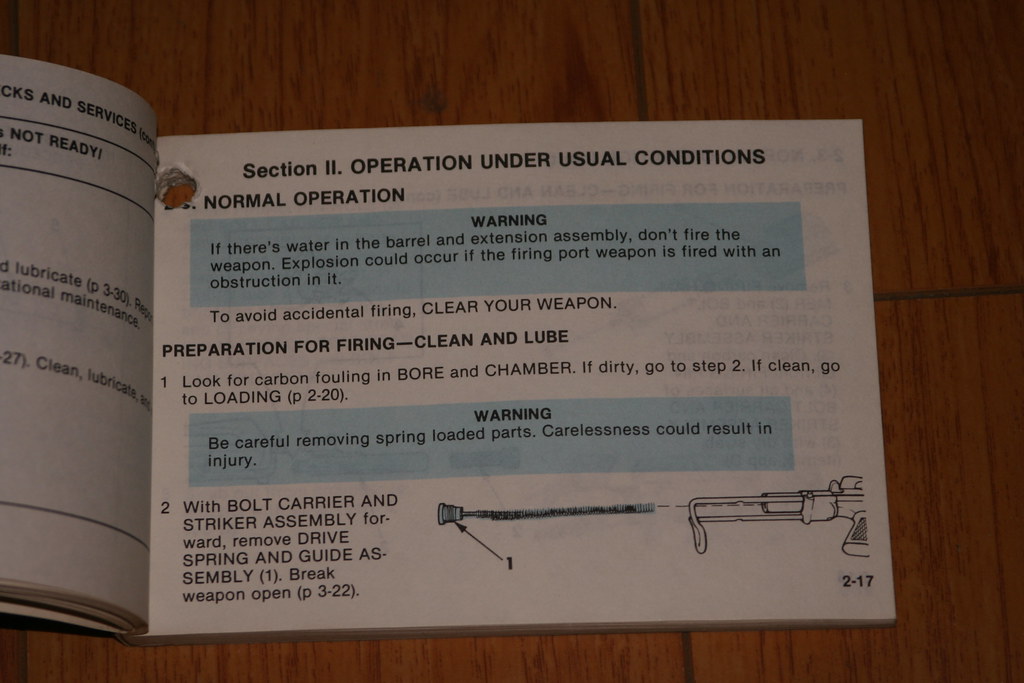

http://www.ar15.com/forums/t_3_123/459672_M231_Firing_Port_Weapon_Review________56K_MASSACRE______________.html

The M231 Bradley Port Firing Weapon was an open bolt weapon using a modified recoil system that used a striker to fire rather than a hammer, so it couldn't be directly translated - but it used a recoil buffer system that consisted of three springs nestled together to control ROF. Granted - I think they made the weapon fire faster, as I've heard anecdotes of people removing some of the springs to slow it down, but I wonder how much you could tune a set of springs - maybe using a single addition spring behind and within the buffer/recoil spring assembly currently in the weapon. I'd wonder if, with a nestled spring design and possibly a lighter buffer (and possibly in conjunction with a lighter bolt carrier) you could speed up the action enough to "outrun" the hammer follow and return to battery in time. As I've mentioned, I've been generally disinterested in hydraulic buffers for the most part, so I haven't followed them closely, but besides Endine, in carbine buffers I'm seeing: The KynSHOT: http://www.armoryblog.com/gun-gear-reviews/kynshot-hydraulic-recoil-buffer-review/ and the Crosshair: http://www.brownells.com/rifle-parts/receiver-parts/recoil-parts/recoil-buffers/ar15-recoil-buffer-carbine-sku100012336-57177-119296.aspx No idea on the relative quality of any of them, though. IIRC Stukas87 likes using hydraulic buffers in his M4A1 lowers - he might have some more word on what's good and what's not. I've never used one in my rifle, and the stated benefits don't seem terribly compelling even for an FA capable M4A1 when coupled with the reports I've seen of breakage/leakage, though some use them very successfully, it would appear - and I'm not sure of the exact reasoning behind using them in an LMG/LSW/IAR variant - I just know that Colt had been experimenting with them in their ACR, LMG, and LSW variants. ~Augee |

|

|

|

Quoted: http://www.ar15.com/forums/t_3_123/459672_M231_Firing_Port_Weapon_Review________56K_MASSACRE______________.html http://farm4.static.flickr.com/3263/2886845488_a23f866576_b.jpg http://farm4.static.flickr.com/3131/2886847424_e7e359f623_b.jpg SNIP ~Augee View Quote Great pictures. It's amazing how close the M16 is to an open bolt, the striker system is so simple. No buffer was needed and just ran off of the extra spring power. The striker system really eliminated timing issues, even if the bolt bounced the primer had already been ignited. |

|

|

|

Here is a video where I attempted to use the SD3G with two fingers like a paintball trigger. It didn't work so well. Splits were in the .16 range. The last four shots of the video were done with just my usual trigger finger and splits were about .14. What this video doesn't show is the large number of times I made the hammer follow the bolt home and had a dead gun

|

|

|

|

Quoted:

Here is a video where I attempted to use the SD3G with two fingers like a paintball trigger. It didn't work so well. Splits were in the .16 range. The last four shots of the video were done with just my usual trigger finger and splits were about .14. What this video doesn't show is the large number of times I made the hammer follow the bolt home and had a dead gun http://youtu.be/iQlEjn-c0dM View Quote Yeah, that wasn't much different than just squeezing it normally. You still have to try stuff to see what does and doesn't work. What was your expected ROF with that technique? |

|

|

|

Quoted:

Here is a video where I attempted to use the SD3G with two fingers like a paintball trigger. It didn't work so well. Splits were in the .16 range. The last four shots of the video were done with just my usual trigger finger and splits were about .14. What this video doesn't show is the large number of times I made the hammer follow the bolt home and had a dead gun View Quote Just because you mentioned it, it reminded me - I have no idea how this would work for this application - but I wonder how one of those "paintball style" AR "double triggers" would work?

http://www.cheaperthandirt.com/product/9-173442 ~Augee |

|

|

|

Quoted: Yeah, that wasn't much different than just squeezing it normally. You still have to try stuff to see what does and doesn't work. What was your expected ROF with that technique? View Quote View All Quotes View All Quotes Quoted: Quoted: Here is a video where I attempted to use the SD3G with two fingers like a paintball trigger. It didn't work so well. Splits were in the .16 range. The last four shots of the video were done with just my usual trigger finger and splits were about .14. What this video doesn't show is the large number of times I made the hammer follow the bolt home and had a dead gun http://youtu.be/iQlEjn-c0dM Yeah, that wasn't much different than just squeezing it normally. You still have to try stuff to see what does and doesn't work. What was your expected ROF with that technique? The deal killer was the hammer follows. I've got videos where I had a dead gun in 3-4 shots. |

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.