|

Posted: 8/5/2012 12:38:07 PM EDT

I've been having some accuracy issues with my new Ruger 22/45. I made a thread in the rimfire pistol forum detailing my problem:

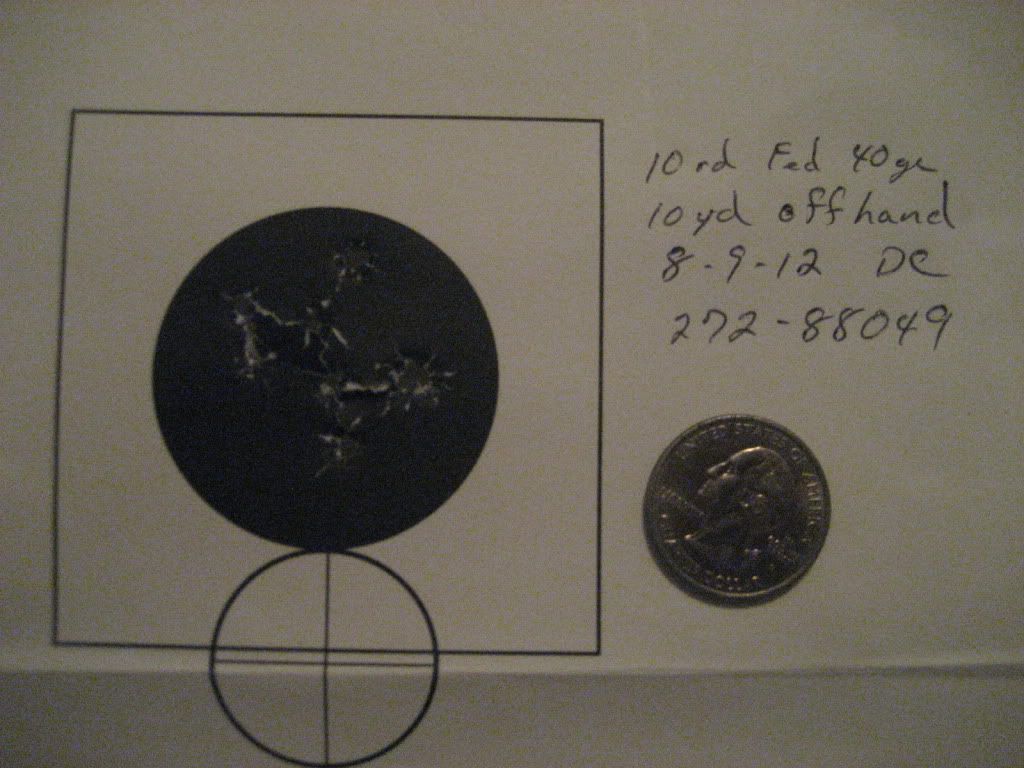

http://www.ar15.com/forums/t_5_50/128225_Ruger_Mk_III_22_45_accuracy_is_bad____or_is_it_me_.html I went to examine the crown, and it looks not like any crown I've ever seen. Although it appears uniform, the crown is ridged like a coin knurl. Is this normal?  UPDATE: Ruger got it today, said they'd fix it up and send a target to confirm that it's shooting straight. I asked about upgrading my fixed sights to adjustable ones so that I can change POA/POI for shooting suppressed. When I asked about doing a credit card transaction over the phone, the tech simply said, "Don't worry about it, we'll install them and send it back to you ASAP." I wasn't sure before but Ruger has pulled through in spades. +1000 for Ruger customer service, truly the best. UPDATE2:  So after waiting like an eager kid for the UPS guy, I got my pistol back today. I was dismayed to see the chatter marks still on the crown. The tech that spoke to me said they should not affect accuracy, I asked him to clean them up anyway...guess he didn't. :  They did, however, send me a target:  True to their word, the gun now sports a nice set of windage and elevation adjustable sights. However, to top it all off, they forgot to send one of my mags back. I'm supposed to get it in another 5-7 business days. Honestly, all I care about is that it shoots as accurately as any other factory 22/45. The crown is an eyesore, and maybe I'll get brave enough to try the brass screw and lapping compound, but probably not if it shoots well. Overall, my customer service experience with Sturm Ruger is meh. |

|

|

|

it really isn't normal? like i said i've never seen anything like it.

could it be that they skipped a clean-up step when they were manufacturing the barrel? |

|

|

|

I thought Ruger only crowned the Mini14s like that... You know, to ensure minute of barn accuracy.

|

|

|

|

Looks like tool chatter marks. Mabey running the cutting bits too long.

|

|

|

|

Hmm...do you think it would result in 2-3" groups firing supported at 7 yards? Seems like everyone else I've spoken to gets MUCH better accuracy from their 22/45s

This sucks. So now I'll probably have to send this in to the tune of...what, like $50 both ways plus FFL fees? FML |

|

|

|

If you buffed it completely smooth would that help alleviate issues? Any one ever had to do this?

|

|

|

|

Quoted:

Hmm...do you think it would result in 2-3" groups firing supported at 7 yards? Seems like everyone else I've spoken to gets MUCH better accuracy from their 22/45s This sucks. So now I'll probably have to send this in to the tune of...what, like $50 both ways plus FFL fees? FML That could easily result in piss poor accuracy. |

|

|

|

Quoted:

If you buffed it completely smooth would that help alleviate issues? Any one ever had to do this? Would have to be uniform the entire circumference. A proper crown is imperative for an accurate barrel. |

|

|

|

Quoted: Nothing a dremel can't fix.  Hell, I think I have done prettier work with a dremel... |

|

|

|

Quoted:

Hmm...do you think it would result in 2-3" groups firing supported at 7 yards? Seems like everyone else I've spoken to gets MUCH better accuracy from their 22/45s This sucks. So now I'll probably have to send this in to the tune of...what, like $50 both ways plus FFL fees? FML If you send to the manufacturer they ship it straight back to your door. Get in touch with them to see if they'll issue an RMA so you only have to pay return shipping, if any. |

|

|

|

Quoted: If you buffed it completely smooth would that help alleviate issues? Any one ever had to do this? You don't know how square the cut is to the bore, do you? But if you were to lap it with a spherical lap, a bit larger in diameter than the bore, you can get pretty close. For a .22 caliber, a good lap is a #10 BRASS dome head wood screw. Use valve grinding compound as the abrasive. When lapping the crown, precess the axis of the lap for the most uniform job. |

|

|

|

Quoted: Hmm...do you think it would result in 2-3" groups firing supported at 7 yards? Seems like everyone else I've spoken to gets MUCH better accuracy from their 22/45s This sucks. So now I'll probably have to send this in to the tune of...what, like $50 both ways plus FFL fees? FML I wouldn't pay to ship their mistake back to them. If you complain loud enough, I doubt you will have to pay shipping. |

|

|

|

Quoted: Quoted: Hmm...do you think it would result in 2-3" groups firing supported at 7 yards? Seems like everyone else I've spoken to gets MUCH better accuracy from their 22/45s This sucks. So now I'll probably have to send this in to the tune of...what, like $50 both ways plus FFL fees? FML If you send to the manufacturer they ship it straight back to your door. Get in touch with them to see if they'll issue an RMA so you only have to pay return shipping, if any. Cool, thanks for the tip, I didn't know that. Man f my luck w/ new guns....  |

|

|

|

Man I called Ruger CS at their AZ offices first thing this AM, I'm 4th in line....

Wait 10 mins, someone says lemme transfer you to AZ, I said No I called AZ to begin with.... Now I'm 7th in line. |

|

|

|

Iw ould just take it to local smith , pay 50$ for a recrown instead of dealing with all the hassle and ruger may not even fix it right or keep the gun for months.

|

|

|

|

You can fix it yourself if you don't want to pay for shipping and mess with the company.

All you need is a drill, a large brass button head screw from lowes, and some lapping compound (or tooth paste). Lots of videos on youtube will show you how to do it. I fixed an $80 .22 years ago using the brass scrwe method and it worked fine. |

|

|

|

Quoted: I thought Ruger only crowned the Mini14s like that... You know, to ensure minute of barn accuracy.  |

|

|

|

|

Ruger is having problems lately with QC. There have been a lot of threads about the inside of the MKIII receivers having severe tool marks, barrel flutes on the stainless hunter models having rust build up from carbon tool remnants, parts out of spec and crowns butchered. They are running their cutting bits too long or too hot and not changing them as often as they should.

I have a MKIII stainless that came with a rust speckled barrel and out of line takedown pin hole in the frame. |

|

|

|

Quoted:

You can fix it yourself if you don't want to pay for shipping and mess with the company. All you need is a drill, a large brass button head screw from lowes, and some lapping compound (or tooth paste). Lots of videos on youtube will show you how to do it. I fixed an $80 .22 years ago using the brass scrwe method and it worked fine. You can't remove that much metal by lapping.

That needs a lathe and proper machining––then lapping. |

|

|

|

Quoted:

Quoted:

You can fix it yourself if you don't want to pay for shipping and mess with the company. All you need is a drill, a large brass button head screw from lowes, and some lapping compound (or tooth paste). Lots of videos on youtube will show you how to do it. I fixed an $80 .22 years ago using the brass scrwe method and it worked fine. You can't remove that much metal by lapping.

That needs a lathe and proper machining––then lapping. http://www.amazon.com/Gunsmithing-Pistols-Revolvers-3rd-Edition/dp/144020389X I have the older edition of this book. He uses the brass screw method. |

|

|

|

Quoted:

Quoted:

Quoted:

You can fix it yourself if you don't want to pay for shipping and mess with the company. All you need is a drill, a large brass button head screw from lowes, and some lapping compound (or tooth paste). Lots of videos on youtube will show you how to do it. I fixed an $80 .22 years ago using the brass scrwe method and it worked fine. You can't remove that much metal by lapping.

That needs a lathe and proper machining––then lapping. http://www.amazon.com/Gunsmithing-Pistols-Revolvers-3rd-Edition/dp/144020389X I have the older edition of this book. He uses the brass screw method. Touching up and polishing is one thing––machining is quite another. You'd have to spend days spinning a screw with lapping compound.

Edit: Fat_McNasty is a gunsmith––send him an IM with a link to this thread and see what he says. |

|

|

|

Quoted: Iw ould just take it to local smith , pay 50$ for a recrown instead of dealing with all the hassle and ruger may not even fix it right or keep the gun for months. Ruger is quick on getting guns fixed and back to you. Had a Single Six lock up tight and took about 2 weeks from shipping to getting it back. O_P had a Blackhawk repaired and they reblued it and replaced the grips at no cost. http://www.theboxotruth.com/docs/edu115.htm |

|

|

|

Quoted: Quoted: Nothing a dremel can't fix.  Hell, I think I have done prettier work with a dremel... I've done a nicer crown with a zero flute chamfering bit and my cordless  |

|

|

|

Quoted:

Hmm...do you think it would result in 2-3" groups firing supported at 7 yards? Seems like everyone else I've spoken to gets MUCH better accuracy from their 22/45s This sucks. So now I'll probably have to send this in to the tune of...what, like $50 both ways plus FFL fees? FML That would definitely cause that to happen. If that was my new gun I'd want a whole new barrel. |

|

|

|

Quoted:

I've been having some accuracy issues with my new Ruger 22/45. I made a thread in the rimfire pistol forum detailing my problem: http://www.ar15.com/forums/t_5_50/128225_Ruger_Mk_III_22_45_accuracy_is_bad____or_is_it_me_.html I went to examine the crown, and it looks not like any crown I've ever seen. Although it appears uniform, the crown is ridged like a coin knurl. Is this normal? http://i1056.photobucket.com/albums/t377/victorvillanueva100/IMG_0827.jpg That is some serious chatter on that "crown". It looks like it was done at way to high of a speed with a floating tool with no lubrication. It's fixable and relatively easy to do so. You can make it satisfactory by using a dremel, yeah I know, with a 3/8 deburring ball. Take a patch, soak it in oil, put it over the muzzle, put the deburring ball on the opening of the muzzle over the patch and turn it at slow speed. Don't apply too much pressure and check frequently on progress. You basically want to keep the pressure centered and even and LIGHT. Do it just enough to remove the chatter marks and you're done. The reason you're getting accuracy issues is that the chatter has created an uneven crown. If you want supreme accuracy potential, you'll need to have a smith put the barrel in a lathe and turn the face of the barrel and recrown it. |

|

|

|

Ruger customer service is very good, send it in.

Posted Via AR15.Com Mobile |

|

|

|

Quoted:

Nothing a dremel can't fix.  probably caused by a dremel |

|

|

|

Quoted:

Nothing a dremel can't fix.  Oddly enough that can be fixed with a dremel bit....I've fixed a crown like that, with a round polishing bit chucked into a cordless drill...Takes 2 sets of eyes, because you have to be perfectly straight, but it can be done...The rifle I did it to shoots fine now. |

|

|

|

Quoted:

You can fix it yourself if you don't want to pay for shipping and mess with the company. All you need is a drill, a large brass button head screw from lowes, and some lapping compound (or tooth paste). Lots of videos on youtube will show you how to do it. I fixed an $80 .22 years ago using the brass scrwe method and it worked fine. As for the drill DON'T use a electric drill, use an old fashion hand cranked one Stuff a cleaning patch down the muzzle 1/2 inch to catch the cutting, makes clean up much easier. I use 240, 320, 500 emery cloth in that order. put a small square under your brass screw. Use a magnifying glass to look at the crown, it should be stepped where the lands and groves are and be symmetrical. |

|

|

|

Quoted:

Tool chatter from the cutter. Yep. Take it to a smithy and have it re-crowned and blued (11 degree target crown). Accuracy should be greatly improved. |

|

|

|

Quoted:

Quoted:

Quoted:

Quoted:

You can fix it yourself if you don't want to pay for shipping and mess with the company. All you need is a drill, a large brass button head screw from lowes, and some lapping compound (or tooth paste). Lots of videos on youtube will show you how to do it. I fixed an $80 .22 years ago using the brass scrwe method and it worked fine. You can't remove that much metal by lapping.

That needs a lathe and proper machining––then lapping. http://www.amazon.com/Gunsmithing-Pistols-Revolvers-3rd-Edition/dp/144020389X I have the older edition of this book. He uses the brass screw method. Touching up and polishing is one thing––machining is quite another. You'd have to spend days spinning a screw with lapping compound.

Edit: Fat_McNasty is a gunsmith––send him an IM with a link to this thread and see what he says. It would only take an hour at the most, being careful. Those chatter marks are maybe .005-.015 deep. I'm not saying it's the best method since re-cutting it on a lathe is the correct way. Just saying it's possible if he wants to avoid the hastle and cost of shipping and is okay with 90-95% accuracy compared to what a proper lathe cut crown would give. Plus there's no guarantee they'll indicate off the bore. They may just toss it in a 3-jaw and cut it, in which case the brass screw may even be a little more accurate or at least as accurate. |

|

|

|

You're cleaning up and smoothing an edge, not cutting a dovetail across a receiver.

|

|

|

|

Quoted:

Quoted:

Quoted:

Quoted:

You can fix it yourself if you don't want to pay for shipping and mess with the company. All you need is a drill, a large brass button head screw from lowes, and some lapping compound (or tooth paste). Lots of videos on youtube will show you how to do it. I fixed an $80 .22 years ago using the brass scrwe method and it worked fine. You can't remove that much metal by lapping.

That needs a lathe and proper machining––then lapping. http://www.amazon.com/Gunsmithing-Pistols-Revolvers-3rd-Edition/dp/144020389X I have the older edition of this book. He uses the brass screw method. Touching up and polishing is one thing––machining is quite another. You'd have to spend days spinning a screw with lapping compound.

Edit: Fat_McNasty is a gunsmith––send him an IM with a link to this thread and see what he says. brass screw.. its magnified, so it looks worse than it is.. they used a 60 deg cutter with spud to cut it, it chattered, cause they went too fast. Id take it to a smith and have them put a stepped target crown on it. But a DYI is the brass screw with grinding compound.. start off with a 120 grit then clean then drop to 240 then drop to 600. |

|

|

|

Quoted:

Quoted:

. brass screw.. its magnified, so it looks worse than it is.. they used a 60 deg cutter with spud to cut it, it chattered, cause they went too fast. Id take it to a smith and have them put a stepped target crown on it. But a DYI is the brass screw with grinding compound.. start off with a 120 grit then clean then drop to 240 then drop to 600. There you go, folks. Thanks for correcting me! |

|

|

|

Quoted:

Hmm...do you think it would result in 2-3" groups firing supported at 7 yards? Seems like everyone else I've spoken to gets MUCH better accuracy from their 22/45s This sucks. So now I'll probably have to send this in to the tune of...what, like $50 both ways plus FFL fees? FML 22/45's are very accurate and yours is not. Send it back and try to get them to pay for the shipping. |

|

|

|

Update: they sent me a next-day air shipping label via e-mail, just dropped it off.

Now, I wait... |

|

|

|

Ruger really went out of their way to make me a satisfied customer. I can't wait to get my gun back.

Update in OP |

|

|

|

Quoted: Excellent.Ruger really went out of their way to make me a satisfied customer. I can't wait to get my gun back. Update in OP Love a happy ending...........as long as youre happy when you get it back. Sounds like they want to keep a customer. |

|

|

|

Just looking at that makes me cringe. I can imagine the sound it made when that cut was done, but there was probably nobody watching or listening to the lathe when it happened.

|

|

|

|

I thought they weren't taking any more orders so they can preserve quality control?

|

|

|

|

Quoted:

I thought they weren't taking any more orders so they can preserve quality control? I have no idea if this is true or not, but perhaps realizing that they were sending stuff like this out the door is the reason why they stopped taking orders. |

|

|

|

I bought a couple of police trade-in GP100's a few years ago. One was missing a ball bearing to hold the cylinder on and the other had end shake. Sent them to Ruger and they fixed them free of charge. No hassle, they did a great job, and got them back to me quick. I think their CS is great. |

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.