|

Posted: 10/22/2014 1:25:58 PM EDT

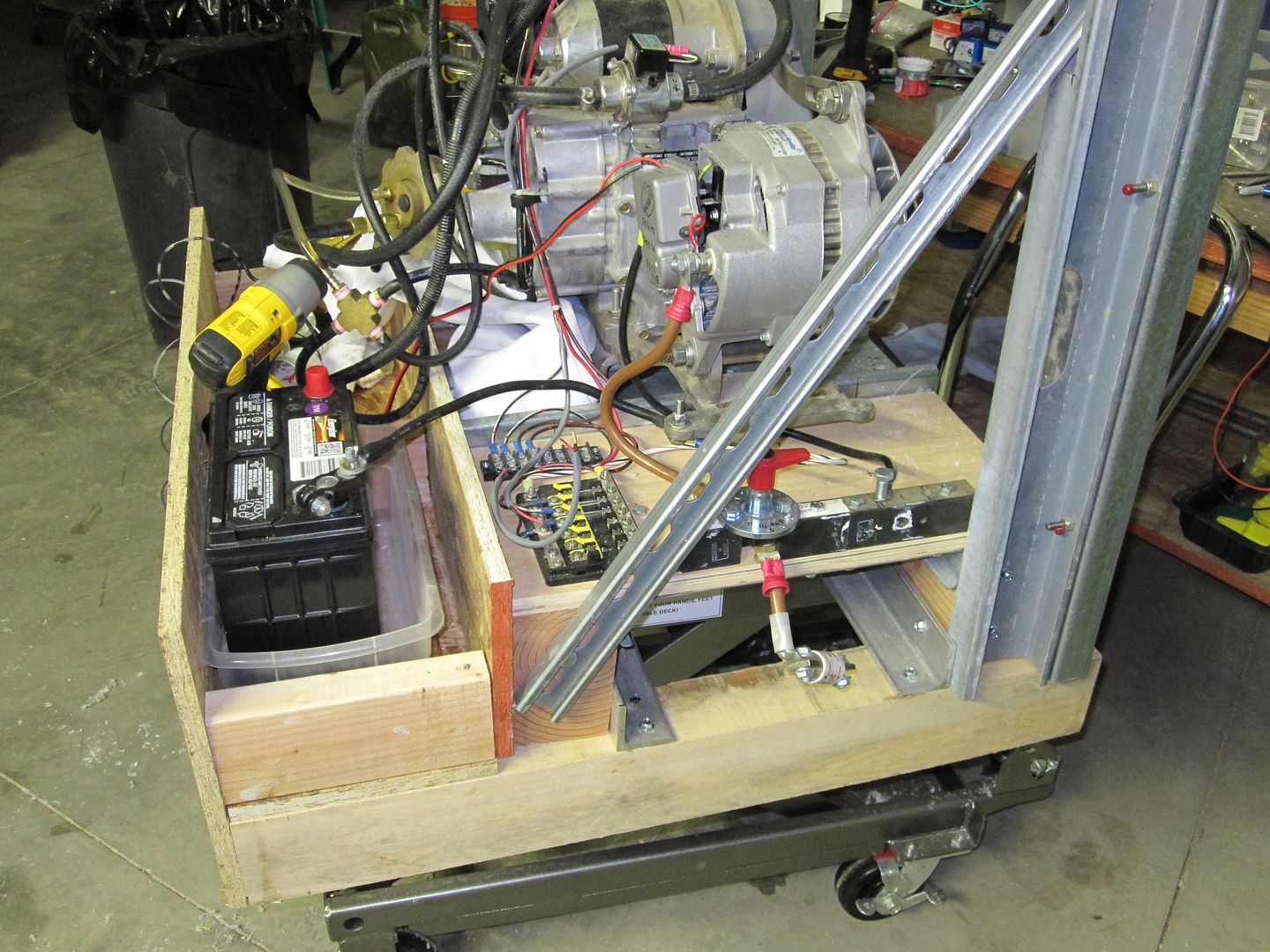

4 HP diesel engine/ Leece Neville 12 volt alter--charging battery bank Part 2 W/ data...

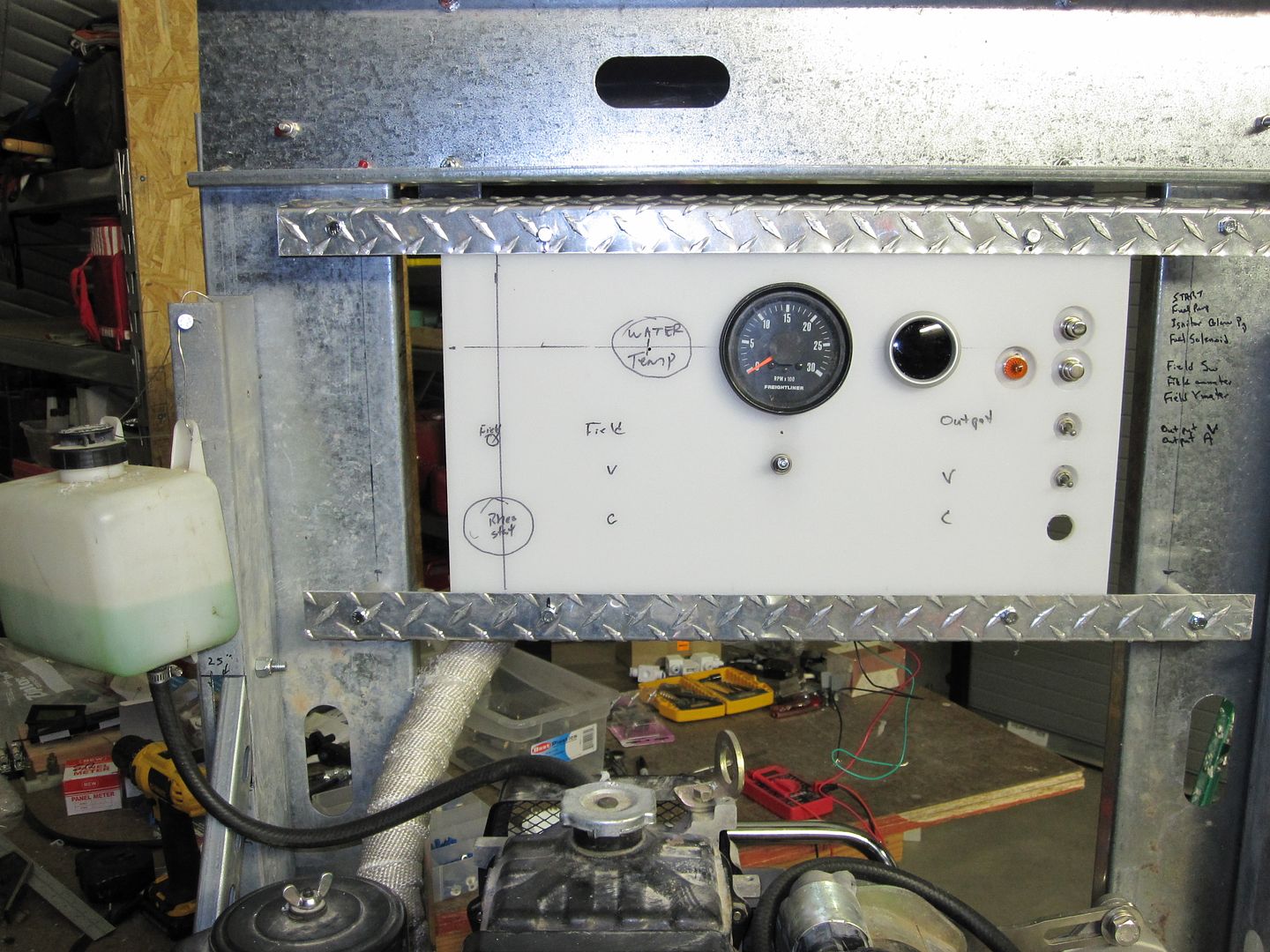

Here's a thread that's been archived re a Kubota 4 HP engine powering a Leece Neville alternator. Kubota genny PART 1 Recently, an instrument panel has been added:

Here's the business part...

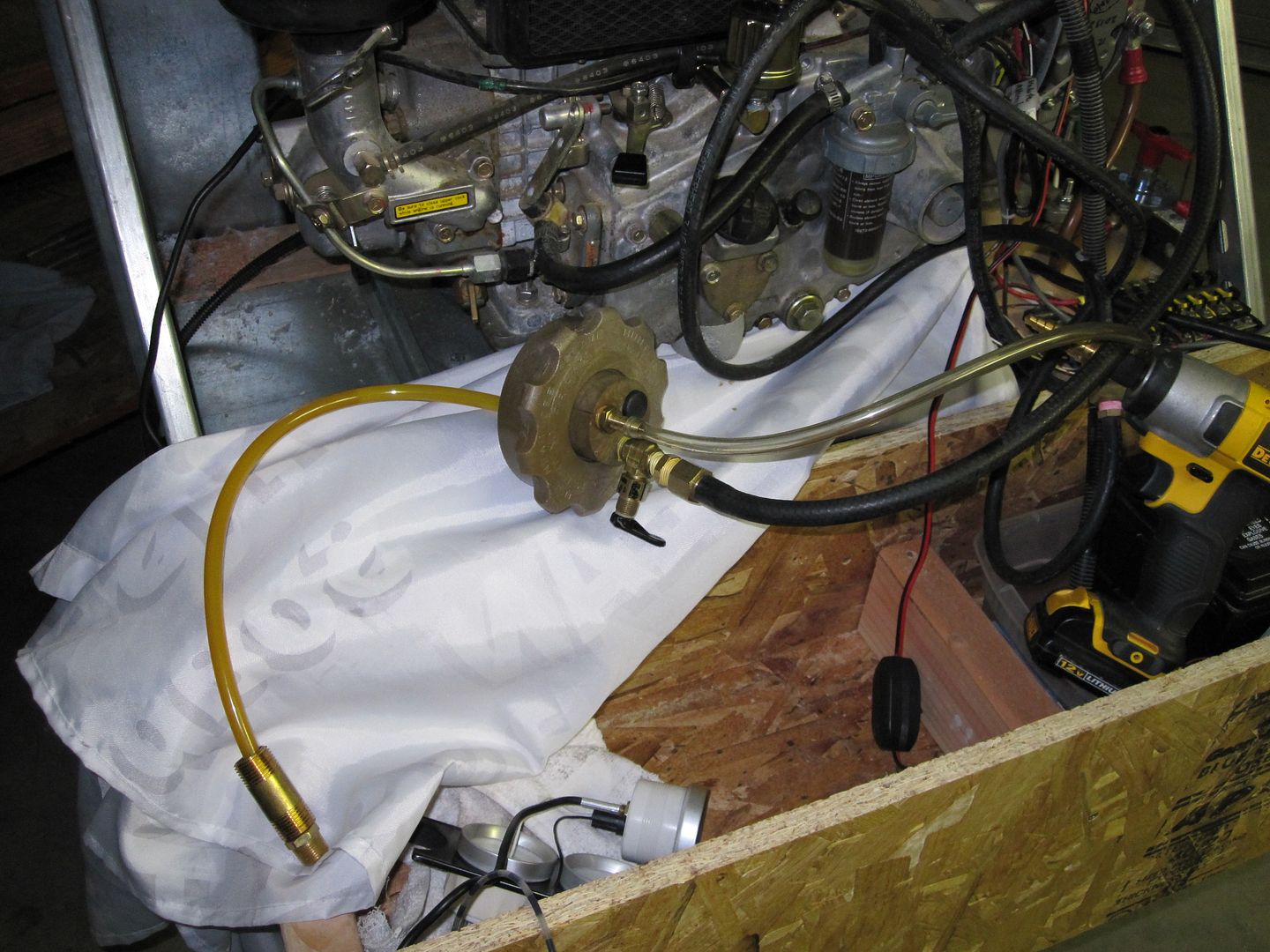

A Scepter fuel can sits in the 'shelf' next to the battery and here's the way the fuel system is plumbed to the fuel can. I changed the way the genny was mounted to the H-F hydraulic table. The genny now has provision to sit on 4 x 4 skids, be raised on the table or be moved with a pallet jack.

The clear hose is the fuel return from the pump... |

|

|

|

|

|

|

|

Very clever set up. I have had a similar alternator for some time, been pondering how to best power it up. Thanks for the tip.

I think the rubber will be okay with the oil, petro product switched to petro product...but I get your drift. Might be worth the effort to build a copper line with ferrels etc. for a permanent set up. I am sure you know but avoid that nylon tubing...always fails when you don't want it to. That has been my general experience with the stuff anyway. |

|

|

|

I suck at electric but did you get it to run at lower amps with a rheostat? How is that setup?

Im a look/hear kinda persoin not a read/pictures. |

|

|

|

|

|

Expy-

Looks great. Nice job, However, points deducted because it is not painted camouflage.

|

|

|

|

Quoted:

Expy- Looks great. Nice job, However, points deducted because it is not painted camouflage.  View Quote Thank you! I appreciate that you appreciate the hard work. Did a lot more work on the solar power system and genny today. Have a lot of pix in my email to upload for both systems. Most of the work involved interfacing the genny power to the solar power panel, revising the disconnects for the genny on both sides, installing some shunts and meter, etc. Thought about the interconnect between the genny charger and the power panel and rewired the genny in two fused branches to the inputs of the big 150 amp circuit breakers -on the battery side. That's so if the CB's both trip, all none of the electronics see anything nasty from the genny/alternator. A lot of stuff. Eating now, will go back to it in a little bit. |

|

|

|

Also found that one of the big breakers had too high a voltage drop across the contacts. Been watching it a few days and could feel a bit of temp rise thru the Bakelite at the location of the contacts, during high charge periods from the panels.

So today I drilled a small hole thru the plastic where the heat was and sprayed some contact cleaner inside. Seems to have fixed the issue. At say 30 amps, the drop is abt 80 mv. |

|

|

|

|

|

Yep, gonna have to add a sense wire.

Just ran it and have abt a volt and 1/2 drop from the alternator to the distribution panel. At 55 amps. Had to turn all the Outbacks' off to get the system to draw more than abt 25 amps from the genny. The engine runs smooth and is fine at 1900 RPM. So, will add a 3rd wire now and see what happens. |

|

|

|

Just tested, will have to remote sense both the neg and pos terminals.

It appears it's easy with these alternators. Gotta love Leece Neville! |

|

|

|

Quoted:

Here's a pix of where the breaker got drilled and injected during it's brain surgery... Symptoms were high contact resistance/voltage drop at higher currents. A long slender drill used for cranial biopsies is pointing to the hole drilled in the patient. http://i994.photobucket.com/albums/af66/expy37/KUBOTAgenrev3186_zps887de802.jpg View Quote do yourself a favor and REPLACE that circuit breaker. Your supposed fix is temporary at best and an extreme hazard at worst. Shoot me a pm if you would like an in depth explanation of why this is not a proper fix. |

|

|

|

Quoted:

do yourself a favor and REPLACE that circuit breaker. Your supposed fix is temporary at best and an extreme hazard at worst. Shoot me a pm if you would like an in depth explanation of why this is not a proper fix. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Here's a pix of where the breaker got drilled and injected during it's brain surgery... Symptoms were high contact resistance/voltage drop at higher currents. A long slender drill used for cranial biopsies is pointing to the hole drilled in the patient. http://i994.photobucket.com/albums/af66/expy37/KUBOTAgenrev3186_zps887de802.jpg do yourself a favor and REPLACE that circuit breaker. Your supposed fix is temporary at best and an extreme hazard at worst. Shoot me a pm if you would like an in depth explanation of why this is not a proper fix. Please send me an internal message, I'm curious. I expect it to live a long and happy life, if it doesn't no biggy. And I will let you know if it doesn't. |

|

|

|

Quoted:

I suck at electric but did you get it to run at lower amps with a rheostat? How is that setup? Im a look/hear kinda persoin not a read/pictures. View Quote Got more info on this from yesterday's tests and will be doing more tests once I get all the sense cable stuff installed and hooked up. Stand by... |

|

|

|

Oh, note the DPDT switch in the bottom center of the instrument panel.

It selects the sense voltage either "Remote" from the battery bank inside the barn ---via the orange wire, or "Local" from the terminals at the alternator. |

|

|

|

|

|

I like this project op . My only thought is that look at a Delco Remy alternator instead of the Leece -Neville . I managed a fleet shop and the Leece-Neville had so much of a higher failure rate that the Delco that we stopped buying the Leece. The current Delco-Remy 24si rated at 150 amps in the same mounts as you are using are also reasonably priced compared to a Leece

|

|

|

|

Quoted:

I like this project op . My only thought is that look at a Delco Remy alternator instead of the Leece -Neville . I managed a fleet shop and the Leece-Neville had so much of a higher failure rate that the Delco that we stopped buying the Leece. The current Delco-Remy 24si rated at 150 amps in the same mounts as you are using are also reasonably priced compared to a Leece View Quote I started out with the Delco, but trying to provide for connections to remote sense and general maintenance, like R&R the VR, I went with the L-N ---and have purchased backups. The brushes can be replaced on the L-N that I'm using in a couple minutes, and there are other maintenance features I like. So, I'm pretty much stuck.

|

|

|

|

Forgot to mention, the current in the alternator's VR reference wires is ~2.2 amps.

Measured with a Fluke clip on ammeter, that are VERY marginally accurate at low current. I suppose a rheostat in series w/ the reference lead would serve to set the constant voltage, but I like the diode solution for accuracy. |

|

|

|

Also wanted to mention, the ability of a cell to accept charge is partly determined by how many sulfur ions in the electrolyte.

As a cell 'sulfates' and forms insoluble sulfur compounds on the plates, sulfur ions are lost from the electrolyte and as the sulfation continues, eventually the electrolyte becomes just plain old water [sorta]. So, you can evaluate the aging of a battery by measuring its specific gravity when it is 'fully' charged. A lowering SG, for a given end charge voltage, suggests some sulfur ions have been lost from the electrolyte. Low SG electrolyte freezes at higher temps, explaining why we see batteries failing in the fall when ambient temps reach freezing. Something to think about [and measure] if you need your battery to work in a SHTF. See page two for electrolyte freezing points vs SG. Electrolyte freezing temps, pg 2 Here's a state of charge vs freezing point chart from Affordable Solar, I think.

It's readily apparent that a poorly working vehicle charging system can lead to a damaged battery in not so cold wx. It's equally apparent, keeping tabs on your battery's SG with a hydrometer or refractometer, and charging system voltage with a Harbor Freight $4 DVM, could save you a breakdown... You do keep a DVM in your vehicle -dontcha? |

|

|

|

240 seems a little high, isn't that about the boiling point of 50/50 ethylene glycol/water mix?

|

|

|

|

Quoted:

240 seems a little high, isn't that about the boiling point of 50/50 ethylene glycol/water mix? View Quote Thanks for pointing this out JC. I looked at the radiator cap and it's rated at 16 psi. I think that may help out with the boiling point. The temperature sensor is right in the head near the exhaust and that's probably the highest temp location to measure it. |

|

|

|

For the techie guys here...

Something I found when working on this little diesel and a small spark ignition engine ---was that low cost Digital voltmeters go totally whacky due to interference from ignition systems. So trying to diagnose battery issues on spark ignition engines with a DVM could be impossible when the engine is running. I picked up a cheapie analog [old timey type with a pointer and scale] meter for about $10 at a box store. It works fine in the presence of the high tension ignition systems. Something to keep in mind. |

|

|

|

Batteries have gotten run down for all the use we've given them, even with over 8 kw harvested many days.

So yesterday I fired up the Kubota/Leece Neville genset and started to get the SG up. [The gen-set works beautifully, and if anyone follows my footsteps, stick with the Leece-Neville alternator for MANY reasons... Stay away from the Delco's, been there done that... Right now between sun [clouds in and out] and the DC genny, they are putting ~150 amps into the battery bank. SG is abt 1260 right now. Talking with the [old-timey and brilliant] engineer who does their battery design, at US Battery a couple years ago, and referring to the info he gave me that I wrote on the wall at the batteries, he recommends charging to 16 vdc for equalization, every 2 weeks [I never do]. He also said to float to 15.5 volts in the summer and 15.6 volts in the winter, for 2 hours each day. |

|

|

|

Something else...

The electrolyte level of the flooded batteries changes dramatically as they are heavily charged. I looked before starting this charge cycle while the SG was low. It looked like they needed water. If I HAD added water, right now they would be well overfilled. All the sulphur ions going back into solution in the electrolyte as the plate reaction goes forward, really swells the liquid. Be careful... |

|

|

|

240 degrees is too high.

Diesel trucks generally run around 205 to 210. Could have a stuck/bad thermostat? |

|

|

|

Quoted:

240 degrees is too high. Diesel trucks generally run around 205 to 210. Could have a stuck/bad thermostat? View Quote No there is no thermostat in this small engine. There is a radiator cap and it's good. The radiator and cooling asm is integral to the head. The service manual doesn't give a temp spec. Yesterday in the sun it got to 250F. That's at the hottest location in the head next to the exhaust port where the sensor well is located. Running fine, today too. The cooling system cap isn't blowing off or anything. Cap is rated at 16 psi IIRC. |

|

|

|

Quoted: No there is no thermostat in this small engine. There is a radiator cap and it's good. The radiator and cooling asm is integral to the head. The service manual doesn't give a temp spec. Yesterday in the sun it got to 250F. That's at the hottest location in the head next to the exhaust port where the sensor well is located. Running fine, today too. The cooling system cap isn't blowing off or anything. Cap is rated at 16 psi IIRC. View Quote View All Quotes View All Quotes Quoted: Quoted: 240 degrees is too high. Diesel trucks generally run around 205 to 210. Could have a stuck/bad thermostat? No there is no thermostat in this small engine. There is a radiator cap and it's good. The radiator and cooling asm is integral to the head. The service manual doesn't give a temp spec. Yesterday in the sun it got to 250F. That's at the hottest location in the head next to the exhaust port where the sensor well is located. Running fine, today too. The cooling system cap isn't blowing off or anything. Cap is rated at 16 psi IIRC. |

|

|

|

Quoted:

Seems darn hot, but a diesel is most efficient the hotter it is until she melts, so View Quote View All Quotes View All Quotes Quoted:

Quoted:

Quoted:

240 degrees is too high. Diesel trucks generally run around 205 to 210. Could have a stuck/bad thermostat? No there is no thermostat in this small engine. There is a radiator cap and it's good. The radiator and cooling asm is integral to the head. The service manual doesn't give a temp spec. Yesterday in the sun it got to 250F. That's at the hottest location in the head next to the exhaust port where the sensor well is located. Running fine, today too. The cooling system cap isn't blowing off or anything. Cap is rated at 16 psi IIRC. That's what I'm thinking... |

|

|

|

Quoted:

There's a new [to me at least] digital DC voltage and current meter that measures high current -typically 100 or 200 amps... And doesn't use a shunt. It uses some sort of toroid [I think on the same principles of DC clip on ammeters] that you have to pass the heavy current carrying inductor thru and these display current in both directions. I.e., charge discharge. Here's a pix from http://www.electronic-circuits-diagrams.com/store/img-large/dc-300v-0-100a-led-digital-voltmeter-ammeter-charge-battery-voltage-current-12v_281766909367.jpg http://www.electronic-circuits-diagrams.com/store/img-large/dc-300v-0-100a-led-digital-voltmeter-ammeter-charge-battery-voltage-current-12v_281766909367.jpg The blue square thing in the picture is the current sensor. A lot of Sellers are offering these on eBay right now and I got one in the other day. The nice thing abt it was the price, only abt $12 or maybe 15, IIRC. Still haven't had time to hook it up and test it, but I'll report when I do. To find the various ones on eBay, need to search 'digital volt amp meter' and similar and look at the pictures until you see the blue sensor. View Quote I think I need one or two of those..... |

|

|

|

Quoted:

It uses some sort of toroid [I think on the same principles of DC clip on ammeters] that you have to pass the heavy current carrying inductor thru and these display current in both directions. View Quote see https://en.wikipedia.org/wiki/Hall_effect_sensor and https://en.wikipedia.org/wiki/Hall_effect_sensor#DC_current_transformers and especially see http://en-us.fluke.com/training/training-library/test-tools/clamp-meters/inside-hall-effect-clamp-meters.html ar-jedi |

|

|

|

Nice build EXPY.

Any idea how much that engine and alternator assembly weigh's, minus the support structure? Thanks. |

|

|

|

I think the engine is around 120# and the alternator is abt 20#...

|

|

|

|

Haven't had the run the 4 HP diesel genny this winter to charge batteries ---since adding panels.

The panels we added have a more difficult time of shedding snow than the 4 original on the S end of the barn and the 3 on the container. They're sloped aggressively... The sun shines against the south bldg. end and heats up those 4 panels as the warm air rises, as well as the end of the container. Wx has been bad for a while and the batteries were running down, even with aggressive load shedding by remote control. The other day wx finally improved and the original panels saved the day at the barn. The night before the battery voltage under small load was 11.6 vdc at a below freezing temp, it was looking like a trip there was in the near future... In one day the 4 old 224 watt Sharp panels on the end of the barn put about 3.9 kw of juice into the batteries. Snow has melted off the other panels considerably, and they're adding a lot of charge too. I figger it will take 12kw+ to get the batteries in the barn topped off. So we can stay here working on projects and staying warm... Surprisingly, the batteries at the container didn't get nearly as low. For the folks who remember the solar box water storage system we built in ~2010, this year is the earliest I've seen it get very close to freezing, about 32.4F. Of course the phase change effect kicks in and there have to be a ton more BTU's exchanged to the outside before it actually freezes hard. After the wx got better, the temp has been going up according to the sensors. Water is close to 40F now, and that's ~120 gallons because SO filled the tank before winter set in. An issue we've always had is the snow falls off the 3 container panels right onto the solar box glass.

|

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.