The design objective of this tool kit is to have the right tool to repair and maintain the BOV with the BOV at all times

Here it is installed. Yea I know the BOV needs to be vaced out, fire extinguisher lives on the other side of the truck

The 349 piece mechanix pro tool set with custom blow molded case on sale at Sears, Home Depot, Lowe’s, etc does not meet the needs that this kit does for applicability, size, and weight reasons.

Applicability: This kit has many tools that are not included in the blow molded case. These tools were selected because they fit some specific fastener on the selected BOV. The tools in this set were bought from a bunch of sources, Salvation Army shop to Snap On truck, the correct tool is where you find it.

Size: This kit also must be compact to enable it to ride inside the BOV and yet be out of the way until needed. The blow molded case is just too big.

Weight: I have another tool box that is as heavy as me, that’s not many tools to a mechanic but it is enough that a box that heavy tends to be left at home. This kit is light enough that my 5 year old can carry it.

To build the kit there are some simple steps:

First; define the level of repair that the kit must support.

Second; measure the BOV to be kitted.

Third; put the correct tools in the box.

First; define repair level. For me with this BOV the answer is best stated as any repair that I would be willing to do in a Wal-Mart parking 250 miles away from home.

So swapping an engine or transmission is off the list, but most lesser jobs are fair game.

Second; measure the BOV to be kitted. It is important to find the tools that fit the job on

that BOV. Pulling the rear spark plugs was an easy 2 minute job on one of my past BOVs

if you had a crowfoot on a 12 inch extension, otherwise you would work for hours. Auto companies make changes at times so there can be variations even within a single model year.

Are you fitting this

or this

Third; put the correct tools in the box. This sounds simple but your brother in law will be over to drink your beer and tell you how to do this and that his BOV don’t use the %$# wrench. If you did steps one and two correctly you will probably have a written list of what tools fit where, I did.

Here are the tools that work for the target BOV

The bag that was conscripted into service first held the tools ok, sorta, but not really right.

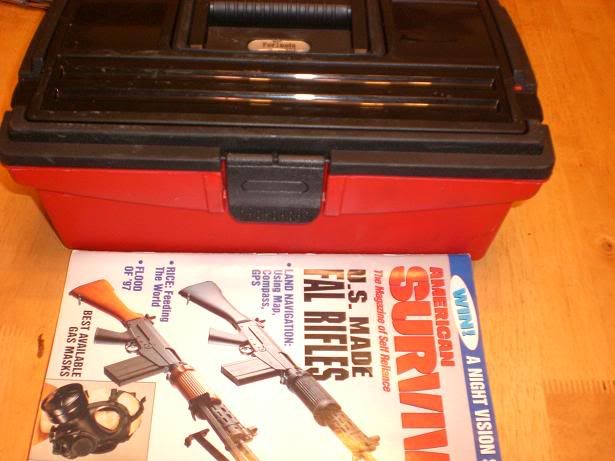

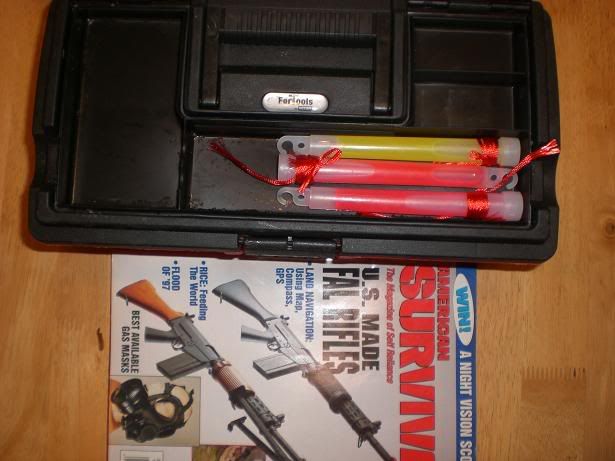

Here is the $2 box that was got for the job, Survival Guide gives a size reference.

I,m adding some glow sticks as I find then on sale, they are to be safety markers if needed.

Everything inside

Lights, electrical, and spanners

Win a FREE Membership!

Win a FREE Membership!